Floor Gun Clips

A technology of floor guns and gun clips, which is applied in the direction of construction and building construction, and can solve the problems of affecting the working efficiency of the floor gun, the falling off of the gun clip, and the inconvenience of nailing, so as to achieve convenient and fast nailing and prevent the nails from falling off , Accurate nailing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

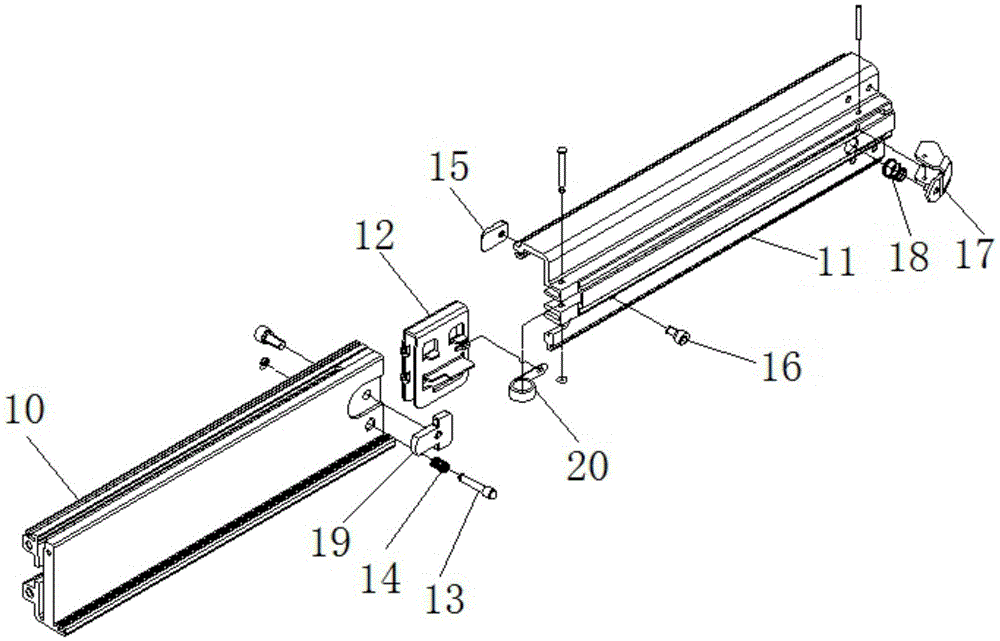

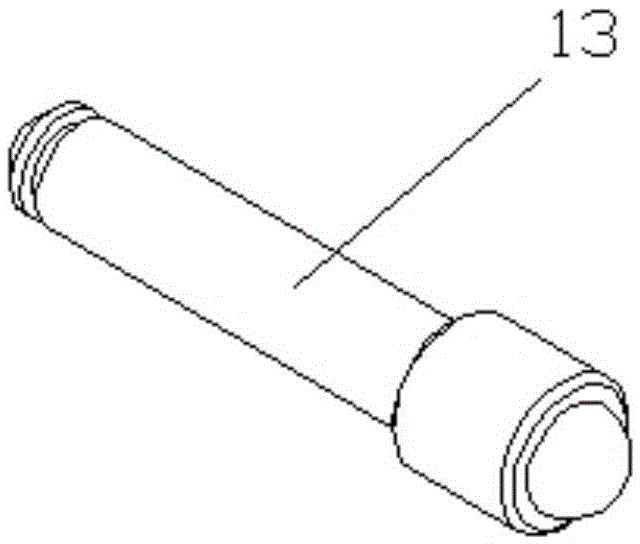

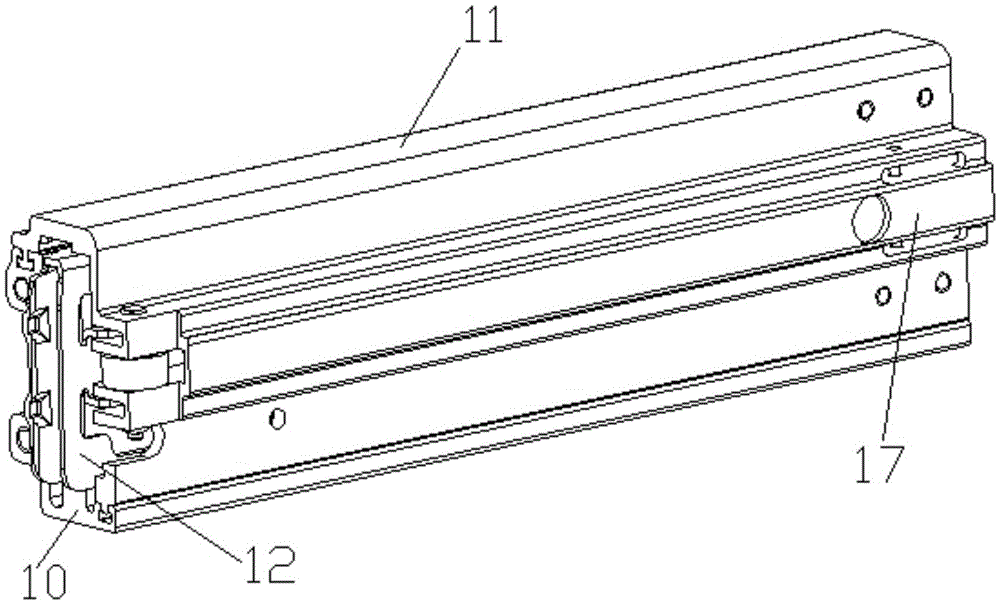

[0024] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 -10: The gun clip of the floor gun, including an outer clip 10 and an inner clip 11, the outer clip 10 is provided with a card slot 10a, and the inner clip 11 is provided with a boss 11a, and the card slot 10a is in phase with the boss 11a Cooperate so that the outer clip 10 and the inner clip 11 are connected and can slide each other. The inner side of the inner clip 11 is equipped with a push nail block 12, and the outer clip 10 is provided with ribs 10b, and the ribs 10b are connected to the described outer clip 10. A nail storage groove 10c is formed between the side walls of the outer clip 10, and the nail pushing block 12 hangs on the rib 10b, and slides along the rib 10b as a guide rail, wherein the outer clip 10 and the The inner folder 11 is provided with a matching locking mechanism, and the specific structure of the locking me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com