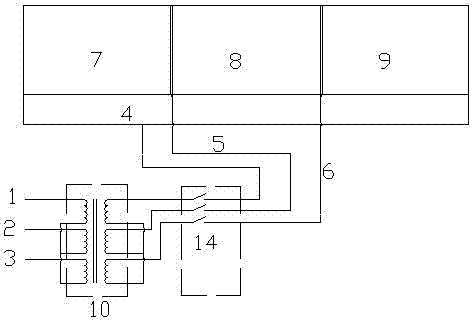

Resistance network facility for removing snows and ices from road and laying and power-supplying method thereof

A technology of laying method and power supply method, which is applied in the direction of roads, roads, pavement details, etc., can solve the problems of difficult control of concrete resistivity, difficult construction, high insulation requirements, etc., and achieve simple and reliable construction and laying, and good consistency of heating power , The effect of stable heating power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0025] The implementation of the technical solution proposed by the present invention is to achieve the goals of simple construction, uniform heating and safe electricity use by rationally designing the resistance network structure, laying method and power supply mode. The specific implementation is as follows:

[0026] A resistance net facility for deicing and snowing on road surfaces, wherein the resistance net is laid between the road surface layer and the surface bearing layer or in the concrete surface layer, and the resistance net is a strip-shaped resistance wire 12 and a columnar metal fixed The distance rods 13 are welded in an orthogonal manner, the distance between the resistance wires 12 is 3~10cm, the distance between the metal distance rods 13 is 4~100cm, and the two ends of the resistance wire 12 are welded with copper wires or copper strips in the orthogonal direction constitute.

[0027] The laying method is that the direction of the resistance wire 12 in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com