Sterilization and heat-insulation coating for textiles and preparation method thereof

A heat-insulating coating and textile technology, which is applied in the direction of textiles, papermaking, and fiber treatment, can solve the problems of unsuitable coating, poor flexibility, compactness and adhesion of heat-insulating coatings, and achieve physical and mental pleasure and good heat insulation effect , the effect of strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

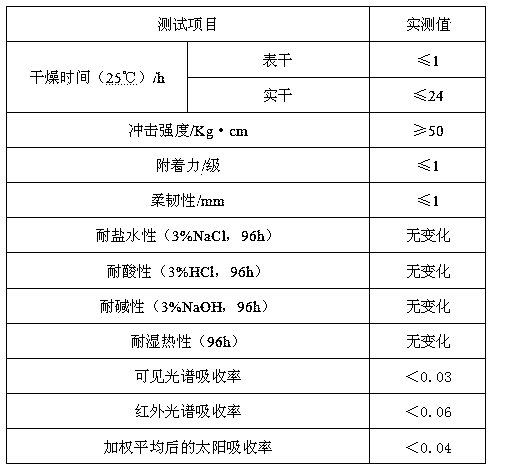

Examples

Embodiment 1

[0018] A bactericidal and heat-insulating coating for textiles, comprising the following components in parts by weight: 60 parts of water-based acrylic resin, 10 parts of fluorocarbon emulsion, 5 parts of nano-titanium dioxide, 5 parts of pigment, 5 parts of polytetrafluoroethylene, and lavender essential oil 1 part, 2 parts of alcohol ester twelve, 1 part of fungicide SCJ-950, 2~4 parts of glyceryl tristearate, 1 part of polydimethylsiloxane, 180 parts of water.

[0019] The preparation method of the bactericidal heat-insulating paint of the textile of the present embodiment, comprises the steps:

[0020] (1) Dry the pigment and PTFE together and grind to 120~200 mesh;

[0021] (2) Add the water-based acrylic resin and glyceryl tristearate into the water, stir, and then add the pigment ground in step (1), polytetrafluoroethylene, nano-titanium dioxide, alcohol ester twelve and fluorocarbon emulsion, Stir at high speed to make it evenly mixed, the stirring speed is 1200r / min,...

Embodiment 2

[0024] A bactericidal and heat-insulating coating for textiles, comprising the following components in parts by weight: 80 parts of water-based acrylic resin, 16 parts of fluorocarbon emulsion, 10 parts of nano-titanium dioxide, 20 parts of pigment, 10 parts of polytetrafluoroethylene, and lavender essential oil 2 parts, 5 parts of alcohol ester twelve, 3 parts of fungicide SCJ-950, 4 parts of glyceryl tristearate, 3 parts of polydimethylsiloxane, 200 parts of water.

[0025] The preparation method of the bactericidal heat-insulating paint of the textile of the present embodiment, comprises the steps:

[0026] (1) Dry the pigment and PTFE together and grind to 120~200 mesh;

[0027] (2) Add the water-based acrylic resin and glyceryl tristearate into the water, stir, and then add the pigment ground in step (1), polytetrafluoroethylene, nano-titanium dioxide, alcohol ester twelve and fluorocarbon emulsion, Stir at high speed to make it evenly mixed, the stirring speed is 1600r / ...

Embodiment 3

[0030] A bactericidal and heat-insulating coating for textiles, comprising the following components in parts by weight: 70 parts of water-based acrylic resin, 14 parts of fluorocarbon emulsion, 8 parts of nano-titanium dioxide, 11 parts of pigment, 7 parts of polytetrafluoroethylene, and lavender essential oil 1.5 parts, 4 parts of alcohol ester twelve, 2 parts of fungicide SCJ-9502, 3 parts of glyceryl tristearate, 2 parts of polydimethylsiloxane, 190 parts of water.

[0031] The preparation method of the bactericidal heat-insulating paint of the textile of the present embodiment, comprises the steps:

[0032] (1) Dry the pigment and PTFE together and grind to 120~200 mesh;

[0033] (2) Add the water-based acrylic resin and glyceryl tristearate into the water, stir, and then add the pigment ground in step (1), polytetrafluoroethylene, nano-titanium dioxide, alcohol ester twelve and fluorocarbon emulsion, Stir at a high speed to make it evenly mixed at a stirring speed of 140...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com