Anti-mite finishing agent, anti-mite finishing method for fabrics and anti-mite fabrics

An anti-mite finishing agent and anti-mite technology, which can be used in fiber treatment, textiles and paper making, etc., can solve the problem of no treatment method, and achieve the effect of comfortable family living environment and good avoidance performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

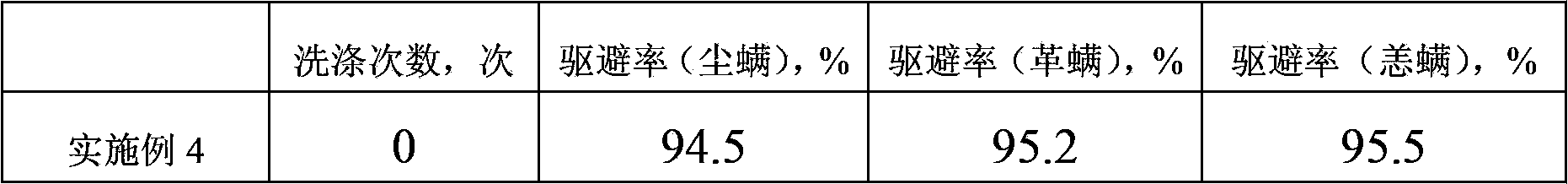

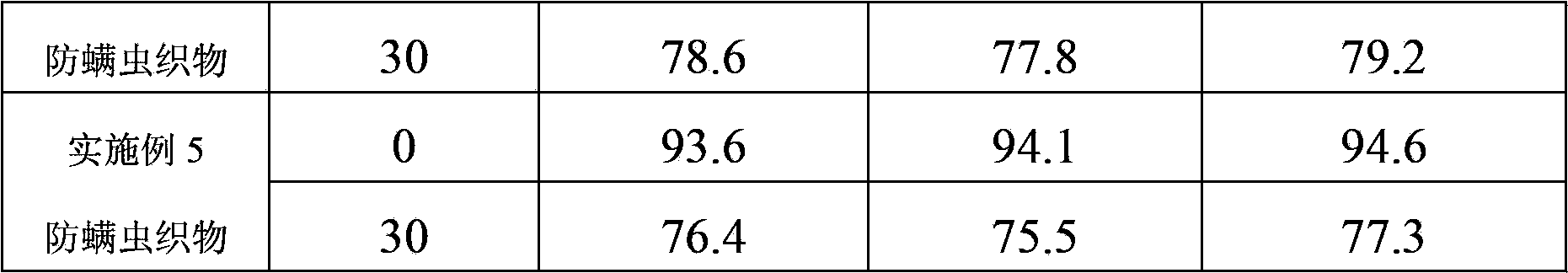

Examples

Embodiment 1

[0029] Each raw material is taken by weighing according to the data of Example 1 corresponding to Table 1. 1,4-Naphthalene 2,3-diyl trithiocarbonate, phenyl 5,6-dichloro 2-trifluoromethylbenzimidazolyl 1-carboxylate, 1-(4-fluoro Phenyl)biguanide hydrochloride, ethylene glycol and sodium dodecyl carboxymethyl imidazoline acetate are stirred and mixed, and sanded evenly to obtain the anti-mite finishing agent of the present invention.

Embodiment 2

[0031] Each raw material is taken by weighing the data of Example 2 corresponding to Table 1. According to the method described in Example 1, the anti-mite finishing agent of the present invention can be obtained.

Embodiment 3

[0033] Each raw material is taken by weighing according to the data of Example 3 corresponding to Table 1. According to the method described in Example 1, the anti-mite finishing agent of the present invention can be obtained.

[0034] Table 1: Formula of anti-mite finishing agent Unit: kg

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com