Method for casting large-sized silicon ingot

A large-size, silicon ingot technology, applied in the field of silicon ingot manufacturing, can solve the problems of danger, slow chemical material, low power output of bottom heater, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

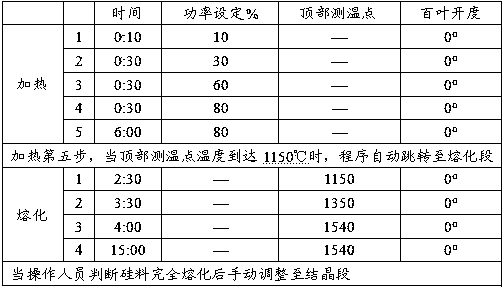

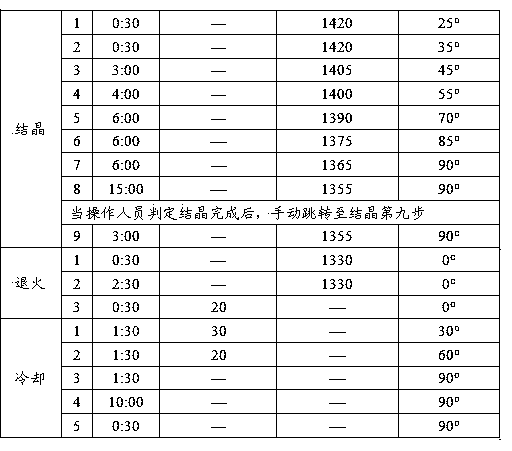

[0029] Such as Figure 1-3 Shown, a kind of method of casting large-scale silicon ingot, comprises the following steps:

[0030] The first step is to transform the thermal field of the G5 ingot furnace, which specifically includes the following steps: 1) Remove the original heat insulation baffle 8 of the G5 ingot furnace to ensure that there is enough space in the thermal field; 2) Remove the shutters 5 The heat-insulating carbon felt 13 on the upper part increases the heat dissipation window area inside the thermal field of the ingot furnace; 3) Move the temperature measuring point on the top of the thermal field outward by 50mm-70mm to ensure that the graphite side guard plate of the G6 ingot furnace will not scrape with the thermocouple 4) Replace the graphite side guard plate 2, graphite bottom plate 9 and quartz crucible 1 in the G5 ingot furnace with the graphite side guard plate, graphite bottom plate and quartz crucible of the G6 ingot furnace.

[0031] The second st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com