Quasi beta forging process for TC25 titanium alloy

A titanium alloy and process technology, which is applied in the quasi-β forging process field of TC25 titanium alloy, can solve the problems of long production cycle and high production cost, and achieve the effects of fast hammering speed, excellent mechanical properties and excellent organizational state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

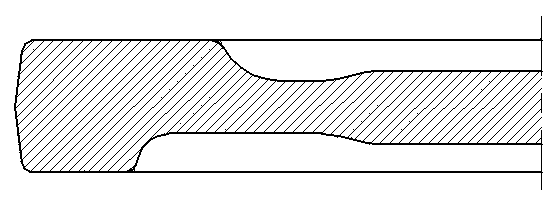

Image

Examples

Embodiment 1

[0013] Processing a kind of TC25 alloy disc class forgings, it comprises the following process steps:

[0014] (1) Cutting: Grinding the edge of the bar into rounded corners;

[0015] (2) Billet making: heating the bar and upsetting the bar by free forging, and then spraying Ti-1 protective agent on the surface of the billet;

[0016] (3) Heating the billet before forging: the billet is heated at medium temperature, the heating temperature at medium temperature is Tβ-30°C, and the heating coefficient at medium temperature is 0.8min / mm; then the billet is heated at high temperature, the heating temperature at high temperature is Tβ+20°C, and the heating coefficient at high temperature is heating The coefficient is 0.5min / mm;

[0017] (4) Die forging: assemble the forging die on a high-energy screw press, put the billet heated before forging into the forging die, and die-forge the billet by the high-energy screw press; the deformation of the forging during the die forging proce...

Embodiment 2

[0020] Processing a kind of TC25 alloy disc class forgings, it comprises the following process steps:

[0021] (1) Cutting: Grinding the edge of the bar into rounded corners;

[0022] (2) Billet making: heating the bar and upsetting the bar by free forging, and then spraying Ti-1 protective agent on the surface of the billet;

[0023] (3) Heating the blank before forging: the blank is heated at medium temperature, the heating temperature at medium temperature is Tβ-10°C, and the heating coefficient at medium temperature is 0.6min / mm; then the blank is heated at high temperature, the heating temperature at high temperature is Tβ+5°C, and the heating coefficient at high temperature is heating The coefficient is 0.6min / mm;

[0024] (4) Die forging: assemble the forging die on a high-energy screw press, put the billet heated before forging into the forging die, and die forge the billet by the high-energy screw press; the deformation of the forging during the die forging process i...

Embodiment 3

[0026] Processing a kind of TC25 alloy disc class forgings, it comprises the following process steps:

[0027] (1) Cutting: Grinding the edge of the bar into rounded corners;

[0028] (2) Billet making: heating the bar and upsetting the bar by free forging, and then spraying Ti-1 protective agent on the surface of the billet;

[0029] (3) Heating the blank before forging: the blank is heated at medium temperature, the heating temperature at medium temperature is Tβ-20°C, and the heating coefficient at medium temperature is 1.0min / mm; then the blank is heated at high temperature, the heating temperature at high temperature is Tβ-10°C, and the heating coefficient at high temperature is heating The coefficient is 0.4 min / mm;

[0030] (4) Die forging: assemble the forging die on a high-energy screw press, put the billet heated before forging into the forging die, and die forge the billet by the high-energy screw press; the deformation of the forging during the die forging process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com