Method for producing neomycin by replacing part of fermenting raw materials with soybean meal

A technology for replacing part and fermenting raw materials, applied in the biological field, can solve the problems of high cost and complex raw material formula of culture medium, and achieve the effects of alleviating the pressure of environmental protection, being beneficial to warehouse management and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

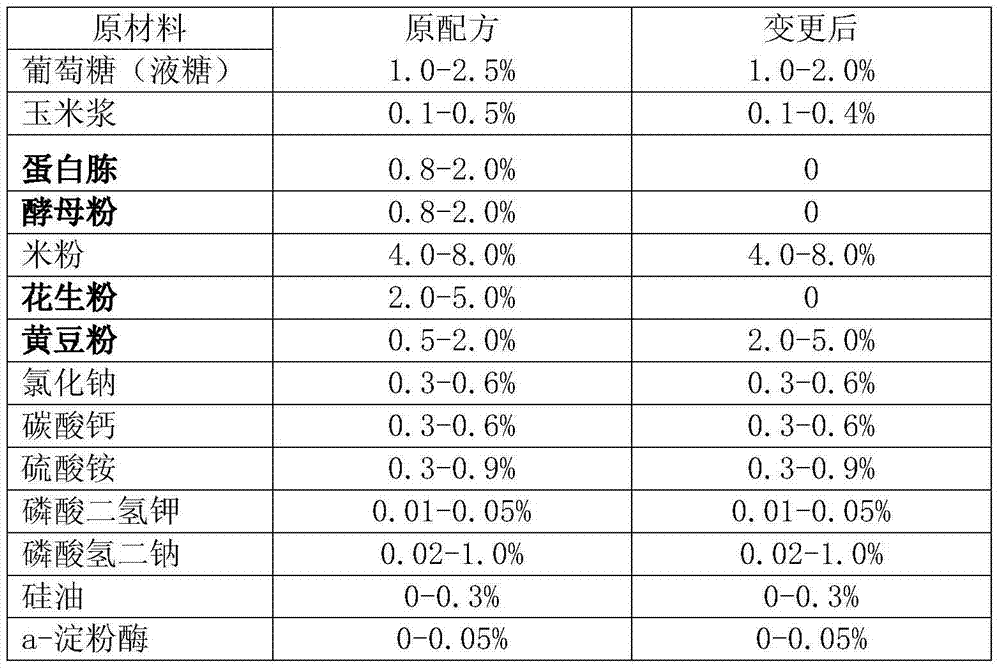

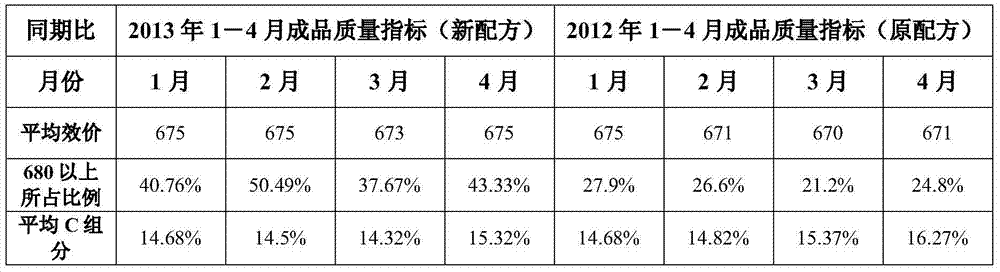

Method used

Image

Examples

Embodiment 1

[0034] A method for producing neomycin by substituting soybean flour for part of fermented raw materials, the method consists of the following steps:

[0035] 1) Cultivation of inclined spores: the sand spores are sealed, dried, and stored at 0-4°C to obtain inclined spores;

[0036] 2) Cultivate the slant spore suspension: culture the slant spore at 28±2°C for 4 to 12 days to prepare the slant spore suspension;

[0037] 3) Seed tank culture: Put the slant spore suspension into the seed culture tank for cultivation. The culture solution in the seed tank includes soybean powder with a mass content of 2.0% of the mass of the culture solution in the fermenter, and the culture solution in the seed tank does not contain peptone, yeast powder and peanut powder;

[0038] 4) Fermentation tank culture: send the culture liquid cultivated in the seed tank into the fermentation culture tank for cultivation. The culture liquid in the fermenter includes soybean powder with a mass content o...

Embodiment 2

[0049] A method for producing neomycin by substituting soybean flour for part of fermented raw materials, the method consists of the following steps:

[0050] 1) Cultivation of inclined spores: the sand spores are sealed, dried, and stored at 0-4°C to obtain inclined spores;

[0051] 2) Cultivate the slant spore suspension: culture the slant spore at 28±2°C for 4 to 12 days to prepare the slant spore suspension;

[0052] 3) Seed tank culture: Put the slant spore suspension into the seed culture tank for cultivation. The culture solution in the seed tank includes soybean powder with a mass content of 5.0% of the mass of the culture solution in the fermenter, and the culture solution in the seed tank does not contain peptone, yeast powder and peanut powder;

[0053] 4) Fermentation tank culture: send the culture liquid cultivated in the seed tank into the fermentation culture tank for cultivation. The culture liquid in the fermenter includes soybean powder with a mass content o...

Embodiment 3

[0064] A method for producing neomycin by substituting soybean flour for part of fermented raw materials, the method consists of the following steps:

[0065] 1) Cultivation of inclined spores: the sand spores are sealed, dried, and stored at 0-4°C to obtain inclined spores;

[0066] 2) Cultivate the slant spore suspension: culture the slant spore at 28±2°C for 4 to 12 days to prepare the slant spore suspension;

[0067] 3) Seed tank culture: Put the slant spore suspension into the seed culture tank for cultivation. The culture solution in the seed tank includes soybean powder with a mass content of 3.0% of the mass of the culture solution in the fermenter, and the culture solution in the seed tank does not contain peptone, yeast powder and peanut powder;

[0068] 4) Fermentation tank culture: send the culture liquid cultivated in the seed tank into the fermentation culture tank for cultivation. The culture liquid in the fermenter includes soybean powder with a mass content o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com