Compound biological agent for enabling acidified marsh gas fermentation system to restore gas production and preparation method thereof

A technology of biological preparations and fermentation systems, applied in biochemical equipment and methods, methods based on microorganisms, fermentation, etc., can solve problems such as long-term domestication, a large amount of manpower, material resources, and losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

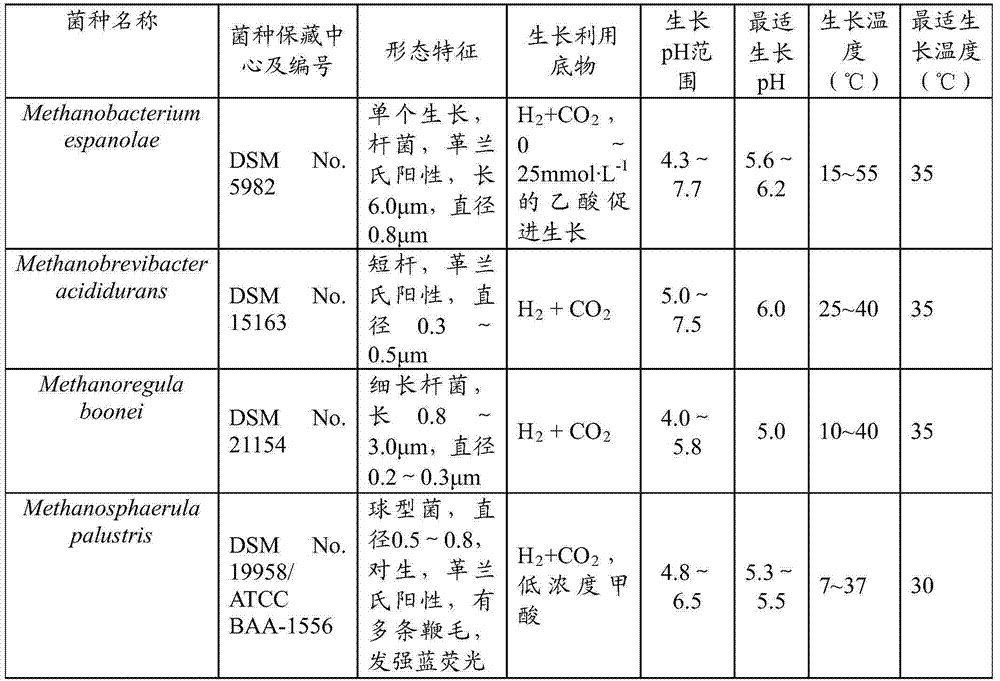

[0062] The preparation of the mixed bacterial liquid of embodiment 1 acidophilic acid-resistant methanogen

[0063] (1) Preparation of Methanobacterium espanolae single bacterial solution

[0064] According to the medium formula numbered DSM No.506 provided by the German Culture Collection Center, the volume percentage content is 80% H 2 +20%CO 2 Prepare the liquid medium of Methanobacterium espanolae under the anaerobic conditions, adjust the pH value to 5.6-6.2, and pack them in 25mL anaerobic tubes, 500mL anaerobic bottles and 20L anaerobic tanks under the above anaerobic conditions, and the filling volume is It is advisable not to exceed 20% of the total volume of the anaerobic tube, anaerobic bottle or anaerobic tank. Cover the airtight cover and sterilize at 121°C for 20 minutes. Filled with 80% H by volume 2 +20%CO 2 The gas is inflated to an anaerobic tube or anaerobic bottle or anaerobic tank with a gas pressure of 100kPa. The live bacterial culture of Methanobac...

Embodiment 2

[0075] Example 2 Preparation of mixed bacterial liquid of acidophilic and acid-resistant methanogens

[0076] According to the needs of production, the scale of cultivation can be expanded and four-level cultivation can be carried out. Set 1m 3 The anaerobic tank is used as four-level culture, and the medium formula, inoculation method, culture conditions, and mixed volume ratio of the mixed bacterial solution of the corresponding bacterial species are the same as in Example 1.

Embodiment 3

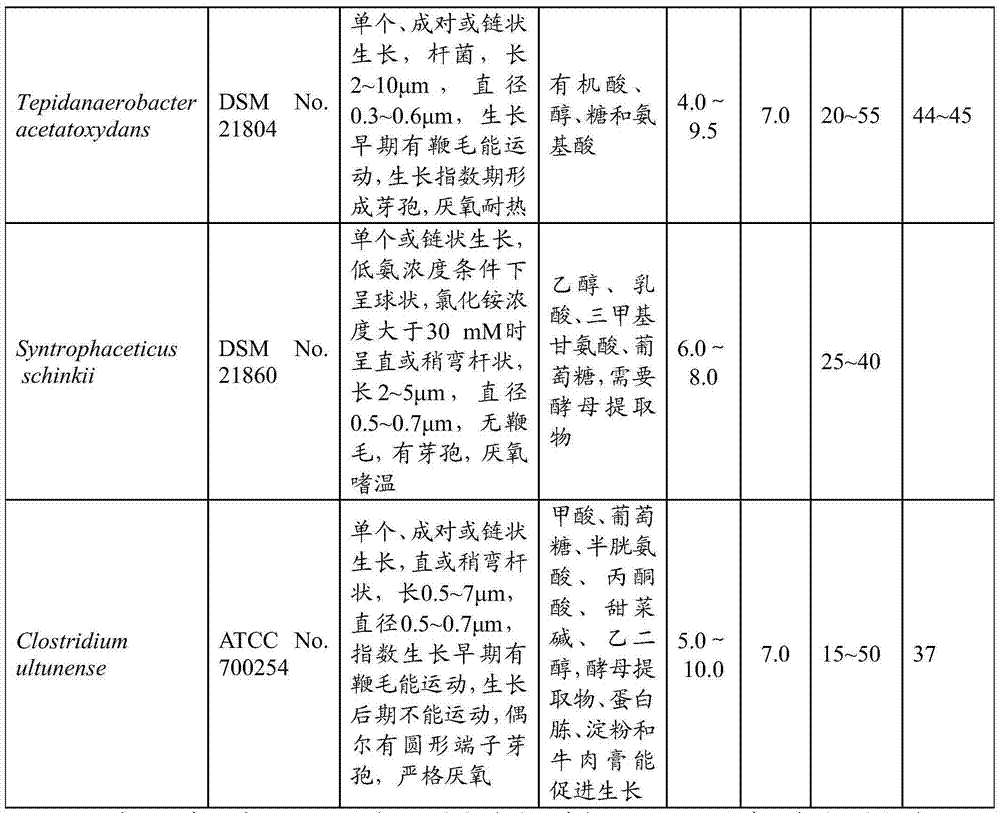

[0077] The preparation of the mixed bacteria liquid of embodiment 3 intertrophic acetic acid oxidizing bacteria

[0078] (1) Tepidanaerobacter acetatoxydans single bacterial solution preparation

[0079] According to the medium formula numbered DSM No.1301 provided by the German Culture Collection Center, the volume percentage content is 80% N 2 +20%CO 2 Prepare the liquid culture medium of Tepidanaerobacter acetatoxydans under the anaerobic conditions, adjust the pH value to 7.0-7.2, and pack them in 25mL anaerobic tubes, 500mL anaerobic bottles and 20L anaerobic tanks under the above-mentioned anaerobic conditions. It is advisable not to exceed 50% of the total volume of the anaerobic tube, anaerobic bottle or anaerobic tank. Cover the airtight cover and sterilize at 121°C for 20 minutes. Filled with a volume percentage of 80% N 2 +20%CO 2 The gas is inflated to an anaerobic tube or anaerobic bottle or anaerobic tank with a gas pressure of 100kPa. The live bacterial cul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com