Alcohol oil extraction device in dimethyl ether production system and alcohol oil extraction method

A production system, dimethyl ether technology, applied in the field of alcohol oil recovery method and device, can solve the problems of catalyst deactivation, alcohol oil entry, catalyst color graying, etc., to improve the extraction effect, reduce the concentration of the kettle liquid, completely separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

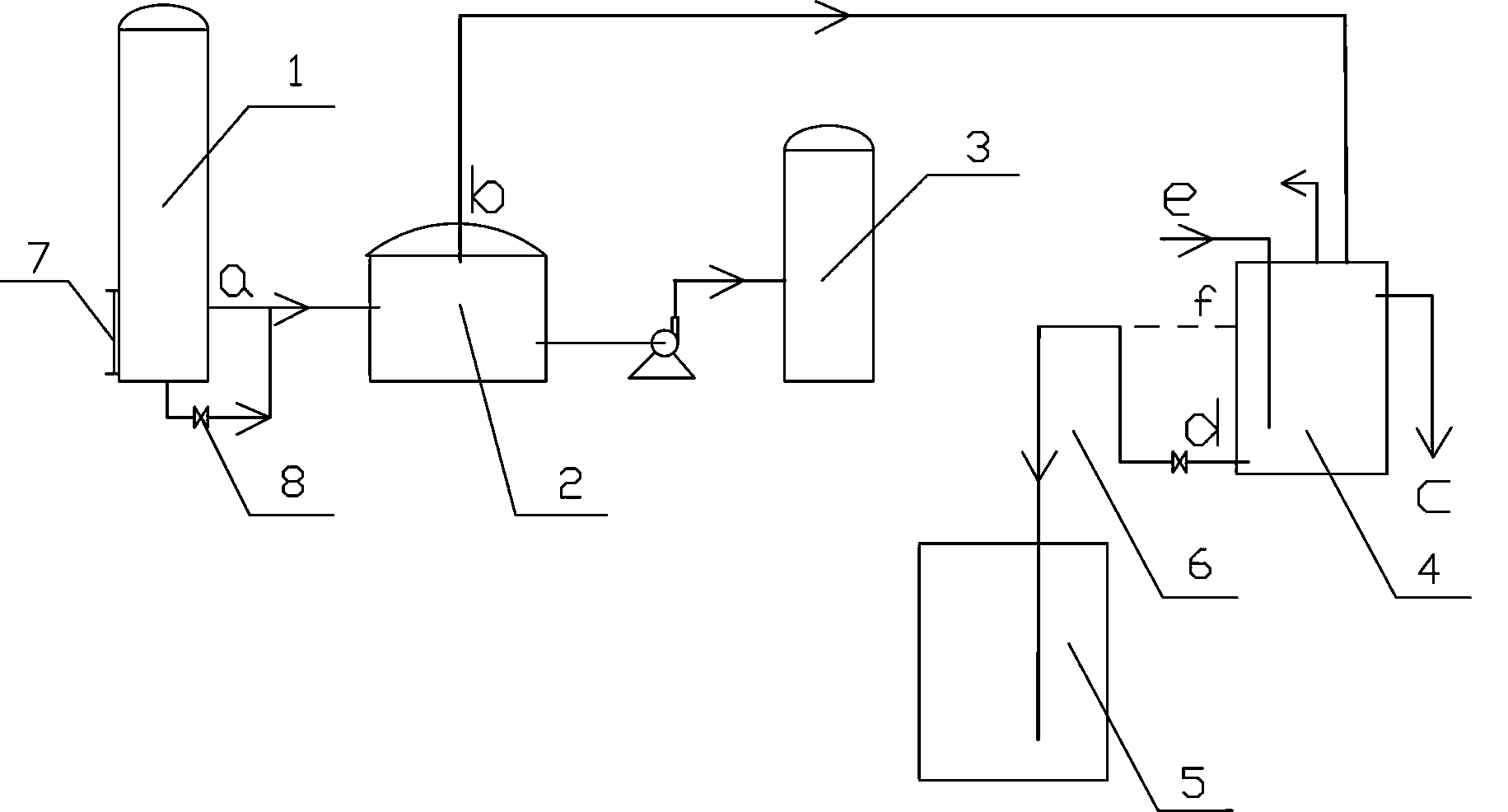

[0017] Example: A method and device for extracting alcohol oil in a dimethyl ether production system, using crude methanol as a raw material to prepare dimethyl ether, and the reaction product obtained by producing dimethyl ether enters the dimethyl ether rectification tower 1 in the dimethyl ether production system for rectification The still liquid in the tower kettle of tower 1 (containing 15% volume methanol, a small amount of alcohol oil, ether and a large amount of water) enters the still liquid buffer tank 2 under the action of pressure difference, and the valve 8 controls the flow of the still liquid. The upper part of the level meter 7 is connected to the production outlet a to the buffer tank 2, and the kettle liquid is stratified in the kettle liquid buffer tank 2. The lower layer is mainly methanol and water, and enters the methanol vaporization tower 3 to further extract methanol. The upper layer is mainly a small amount of methanol and alcohol. oil, ether, etc., e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com