Synthesis method of modified polyurethane resin for circuit board

A technology of polyurethane resin and synthesis method, which is applied in the direction of polyurea/polyurethane coatings, coatings, anti-corrosion coatings, etc., can solve the problems of brittle texture, flexibility and poor adhesion, and achieve increased solubility, good flexibility and Excellent adhesion and fullness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

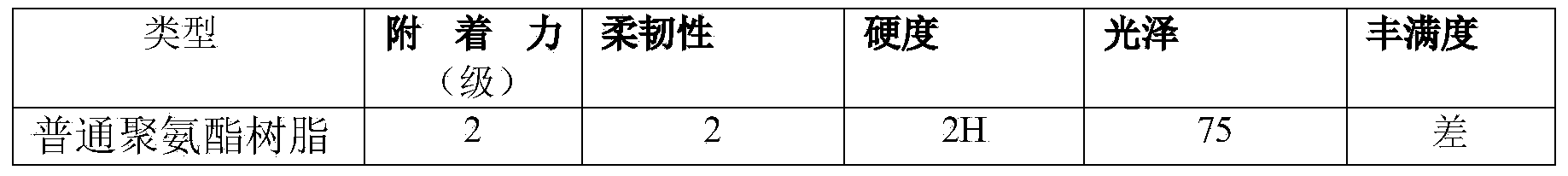

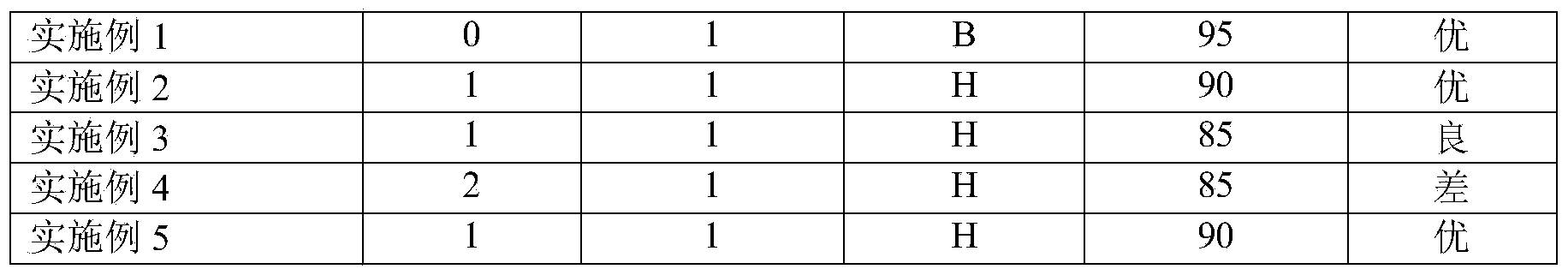

Examples

Embodiment 1

[0024] Embodiment 1: Synthesis of polyhydroxy polyester resin at first: octylic acid and ethylene glycol are 1:2 synthetic polyhydroxy polyester resin of hydroxyl value 500mgKOH / g by weight; Then add 71.6KG (446.8 mol) of polyhydroxy polyester resin, 148.9KG (148.9mol) of polyether polyol resin, wherein the molecular weight of polyether polyol resin is 3000, and the hydroxyl value is 50mg KOH / g. MDI-50298.2KG, ethyl acetate 206.1KG and xylene 238.2KG, heat up to 60°C, after constant temperature reaction for 1 hour, then add 1KG of dibutyltin dilaurate, continue constant temperature reaction for 1 hour, then add neopentyl glycol 18.6KG, after constant temperature reaction for 1 hour, then add 10.6KG trimethylolpropane, after constant temperature reaction for 1 hour, raise the temperature of the reactor to 80°C, after constant temperature reaction for 6 hours, wait for the temperature of the reactor to drop by 59°C, use 32.8 KG of butyl acetate dilutes the product and filters it...

Embodiment 2

[0025] Embodiment 2: Synthesizing polyhydroxy polyester resin at first: be that 1:3 synthetic polyhydroxy polyester resin of hydroxyl value is 500mgKOH / g by carbon nonacid and neopentyl glycol by weight first; Then add in the reaction kettle successively 47.8KG (297.9mol) of polyhydroxy polyester resin (70% solid content), 297.9KG (297.9mol) of polyether polyol resin, wherein the molecular weight of polyether polyol resin is 3000, and the hydroxyl value is 55mg KOH / g . MDI-50298.2KG, ethyl acetate 206.1KG and xylene 238.2KG, then the temperature of the reaction kettle was raised to 60°C, after a constant temperature reaction for 1 hour, 1KG of stannous octoate was added, and the constant temperature reaction was continued for 1 hour, and neopentyl glycol 18.6 After KG, react at a constant temperature for 1 hour, add 10.6KG of trimethylolpropane, keep the temperature at a constant temperature for 1 hour, raise the temperature of the reactor to 80°C, and react at a constant temp...

Embodiment 3

[0026] Embodiment 3: Synthesis of polyhydroxy polyester resin at first: first by dodecanoic acid and trimethylolpropane in a weight ratio of 1:2.5 synthetic polyhydroxy polyester resin with a hydroxyl value of 500mgKOH / g; Add 76.4KG of polyhydroxy polyester resin and 119.1KG of polyether polyol resin, wherein the polyether polyol resin has a molecular weight of 3000 and a hydroxyl value of 60 mgKOH / g. MDI-50298.2KG, ethyl acetate 206.1KG and xylene 238.2KG, the temperature of the reactor was raised to 60°C, and the reaction was performed at a constant temperature for 1 hour. After adding 1KG of bismuth isooctanoate, the reaction was continued at a constant temperature for 1 hour, and after adding 18.6KG of neopentyl glycol ,Constant temperature reaction for 1 hour, after adding 10.6KG of trimethylolpropane, constant temperature reaction for 1 hour, the temperature of the reactor was raised to 80°C, constant temperature reaction for 6 hours, after the temperature of the reactor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com