High flame retardant polyisocyanurate rigid foam and preparation method thereof

A polyisocyanurate and rigid foam technology, applied in the field of polyisocyanurate rigid foam, can solve the problems of easy settlement of solid flame retardants, inability to carry out industrial production, poor environmental protection, etc., and achieve fluidity Good, appropriate degree of cross-linking, improved flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

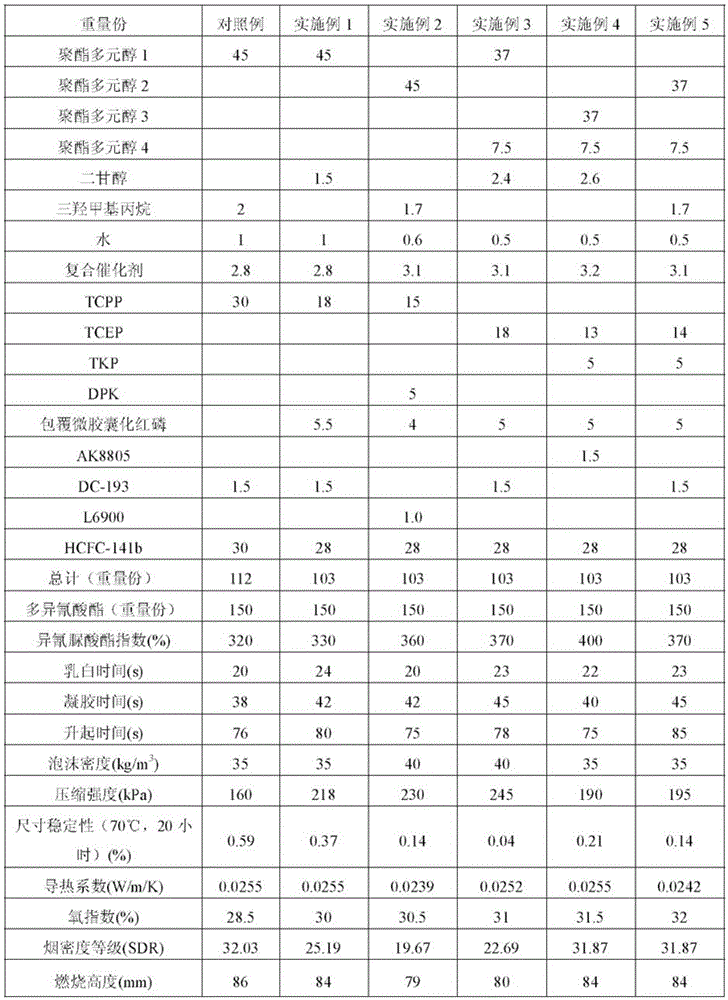

Examples

Embodiment

[0065] The raw materials involved in the following examples are:

[0066] Polyester polyol 1: Modified phthalic anhydride polyester polyol, the hydroxyl value is 230-250mgKOH / g, the functionality is 2, the viscosity at 25°C is about 3000mPa.s, and the average molecular weight is 400- 500, product brand HF-8725, purchased from Zhejiang Huafeng New Material Co., Ltd.

[0067] Polyester polyol 2: modified phthalic anhydride type polyester polyol, the hydroxyl value is 230-250mgKOH / g, the functionality is 2, the viscosity at 25°C is about 3000mPa.s, and the average molecular weight is 400- 500, product brand HF-8724, purchased from Zhejiang Huafeng New Materials Co., Ltd.

[0068] Polyester polyol 3: phthalic anhydride type polyester polyol, the hydroxyl value is 190-200mgKOH / g, the functionality is 2, the viscosity at 25°C is about 15000mPa.s, the average molecular weight is 500-600, the product Brand HF-8020, purchased from Zhejiang Huafon New Materials Co., Ltd.

[0069] Pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com