Preparation method of chitosan and immersion device for preparing chitosan

A liquid immersion device and chitosan technology, applied in the field of chitosan preparation and preparation of chitosan immersion devices, can solve water consumption, energy consumption, acid consumption, alkali consumption, failure of comprehensive utilization of resources, Environmental pollution and other problems, to achieve the effect of saving consumption, easy post-processing, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

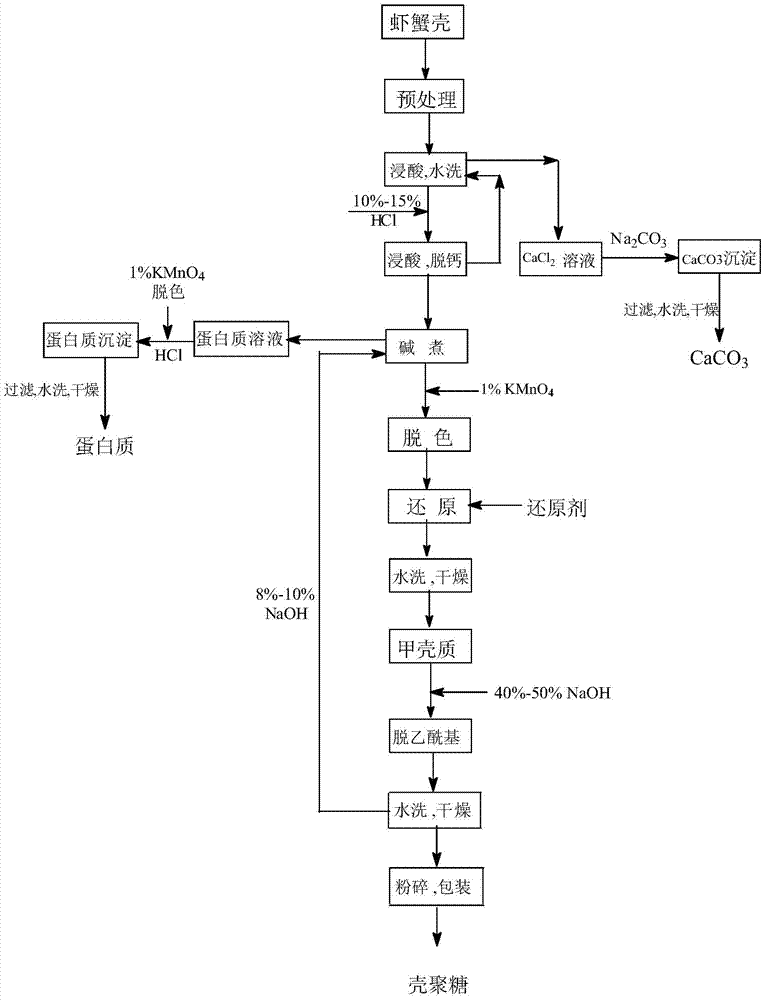

[0042] Shrimp and crab shells are screened, impurity removed, cut into pieces, washed and dried.

[0043] Soak the above-mentioned shrimp and crab shells with an appropriate amount of hydrochloric acid for 6 hours, so that the calcium carbonate and calcium phosphate in the shrimp and crab shells react with hydrochloric acid to form calcium chloride, recycle the calcium chloride after filtering, and collect the shrimp after preliminary decalcification 1. Crab shells; adding an appropriate amount of sodium carbonate solution or introducing carbon dioxide into the recovered calcium chloride solution, filtering, washing with water, and drying to obtain solid calcium carbonate.

[0044] Soak the shrimp and crab shells collected above with an excess of hydrochloric acid with a mass concentration of 12% for 12 hours, stir until no bubbles are formed in the hydrochloric acid solution, and collect the decalcified shrimp and crab shells.

[0045] Boil the shrimp and crab shells collecte...

Embodiment 2

[0050] Shrimp and crab shells are screened, impurity removed, cut into pieces, washed and dried.

[0051] Soak the above-mentioned shrimp and crab shells with an appropriate amount of hydrochloric acid for 5 hours, so that the calcium carbonate and calcium phosphate in the shrimp and crab shells react with hydrochloric acid to form calcium chloride, recycle the calcium chloride after filtering, and collect the shrimp after preliminary decalcification 1. Crab shells; adding an appropriate amount of sodium carbonate solution or introducing carbon dioxide into the recovered calcium chloride solution, filtering, washing with water, and drying to obtain solid calcium carbonate.

[0052] Soak the shrimp and crab shells collected above with an excess of 10% hydrochloric acid for 10 hours, stir until no bubbles are formed in the hydrochloric acid solution, and collect the decalcified shrimp and crab shells.

[0053] Boil the shrimp and crab shells collected above with 8% sodium hydrox...

Embodiment 3

[0058] Shrimp and crab shells are screened, impurity removed, cut into pieces, washed and dried.

[0059] Soak the above-mentioned shrimp and crab shells with an appropriate amount of hydrochloric acid for 8 hours, so that the calcium carbonate and calcium phosphate in the shrimp and crab shells react with hydrochloric acid to form calcium chloride, recycle the calcium chloride after filtering, and collect the shrimp after preliminary decalcification 1. Crab shells; adding an appropriate amount of sodium carbonate solution or introducing carbon dioxide into the recovered calcium chloride solution, filtering, washing with water, and drying to obtain solid calcium carbonate.

[0060] Soak the shrimp and crab shells collected above with an excess of hydrochloric acid with a mass concentration of 15% for 15 hours, stir until no bubbles are formed in the hydrochloric acid solution, and collect the decalcified shrimp and crab shells.

[0061] Boil the shrimp and crab shells collecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com