Optical fiber drawing furnace

A wire drawing furnace and optical fiber technology, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of inability to draw special optical fibers, etc., achieve excellent oxygen removal function, avoid crystallization, and facilitate heat preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

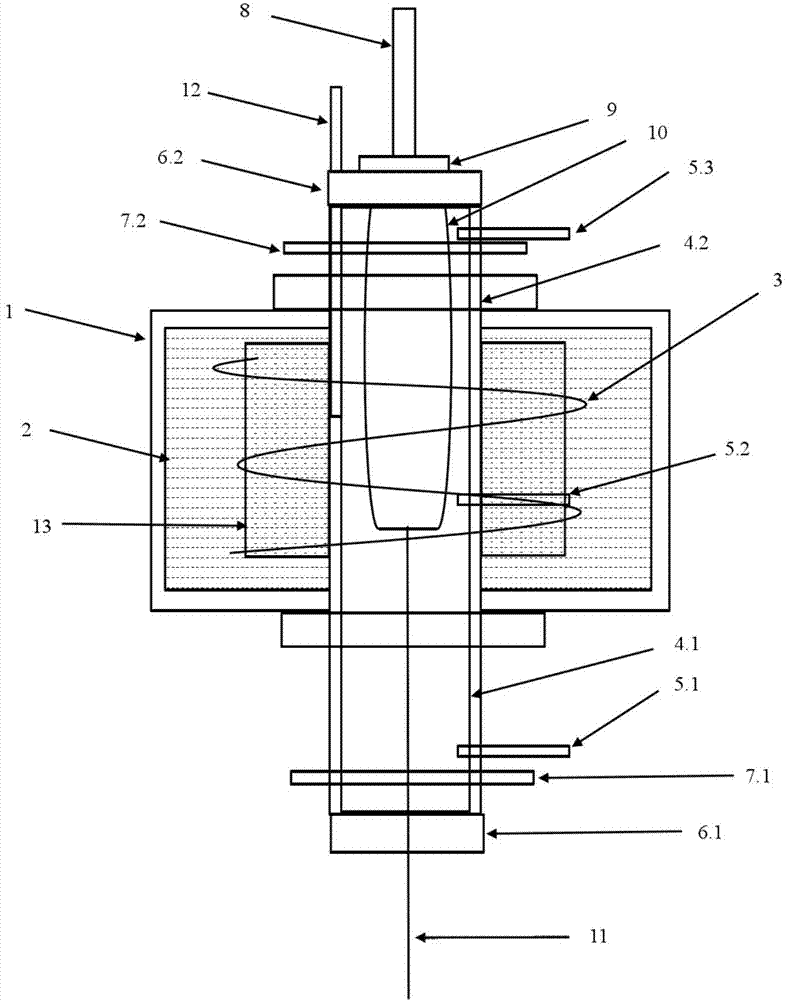

[0014] The technical content of the present invention is to research and prepare an optical fiber drawing furnace for drawing special optical fibers. Helically wound on the heat insulation layer 13, used for heating and heat preservation of the wire drawing furnace; the sealing unit fixed in the middle of the furnace body includes two sealing units, consisting of several layers of middle sleeves, air guide pipes, and sealing devices, which are set for Place the preform and provide a constant temperature and oxygen-free wire drawing environment during the preform drawing process; the first sealing unit is fixed by a quartz outer middle sleeve 4.2, the first fixing frame 7.1, the second fixing frame 7.2, and the second sealing unit The unit is composed of the first sealing unit and the casing 4.2 in the outer layer, and the first sealing device 6.1 and the second sealing device 6.2. Supporting the entire sealing system, the sealing material at the upper and lower ends of the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com