Automatic paperboard staggered stacking device

A technology of misplaced stacking and cardboard, which is applied in the direction of stacking receiving device, thin material handling, transportation and packaging, etc. It can solve the problems of reduced production capacity and production speed, and achieve the effect of increasing production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below with reference to the drawings and embodiments.

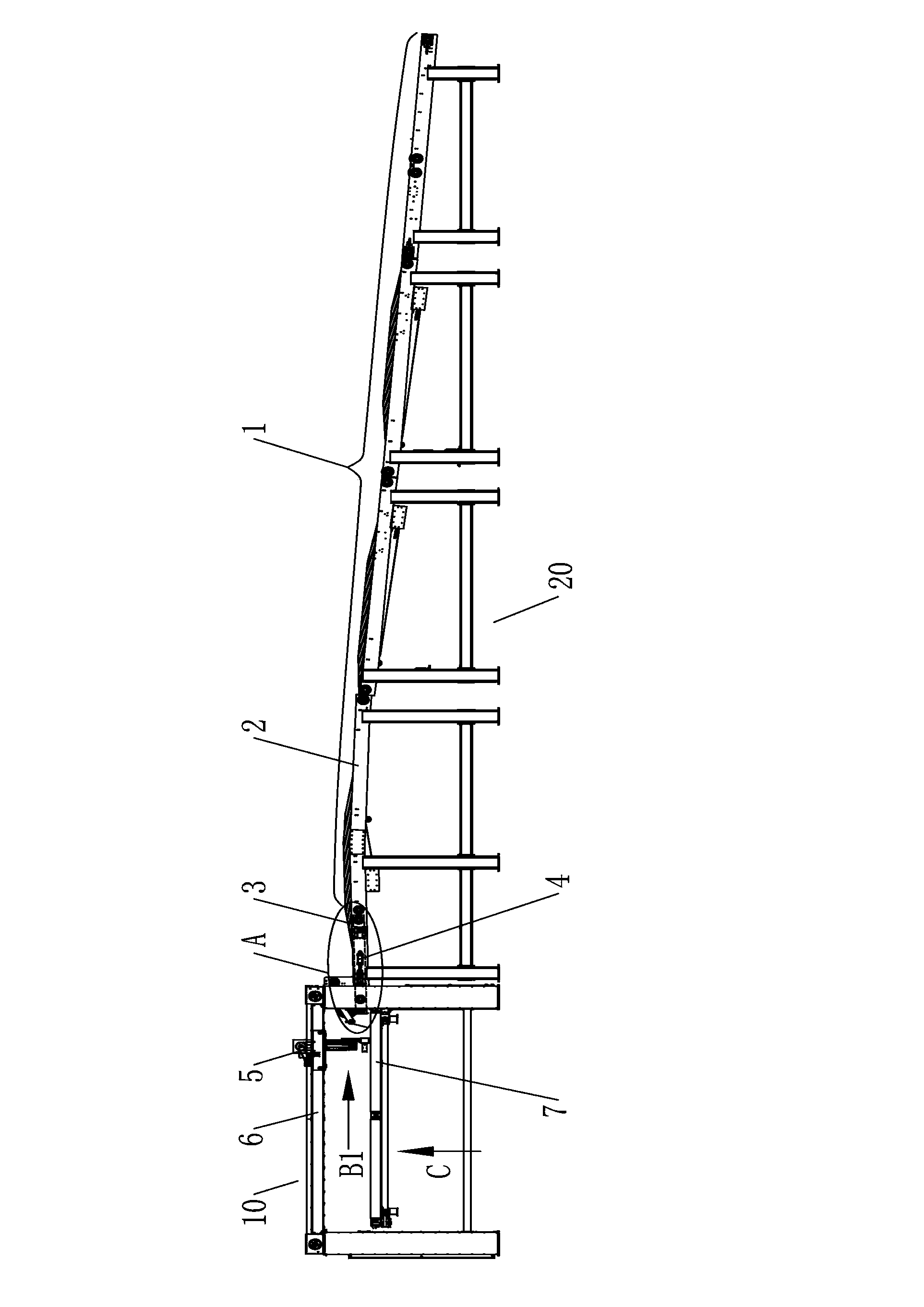

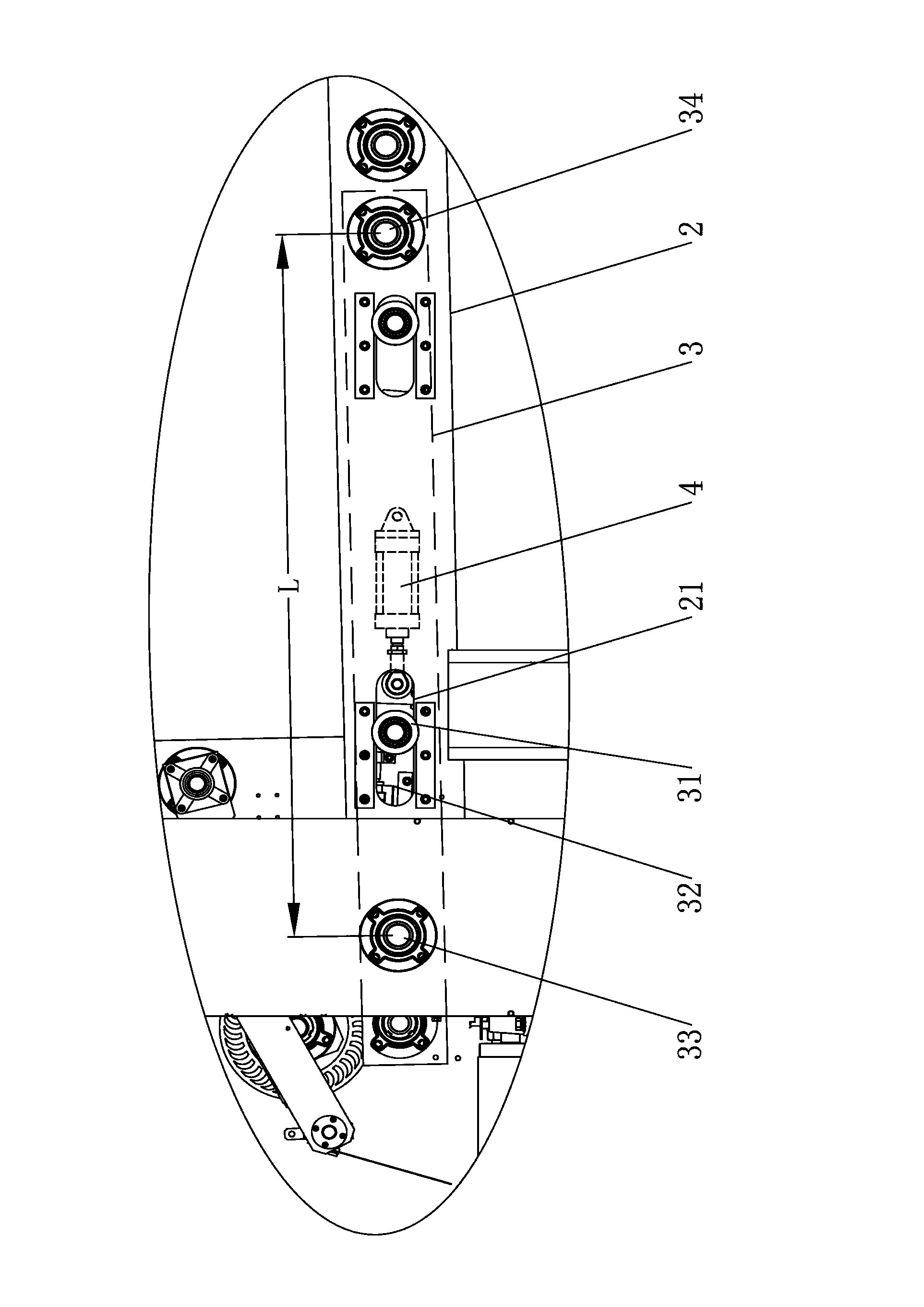

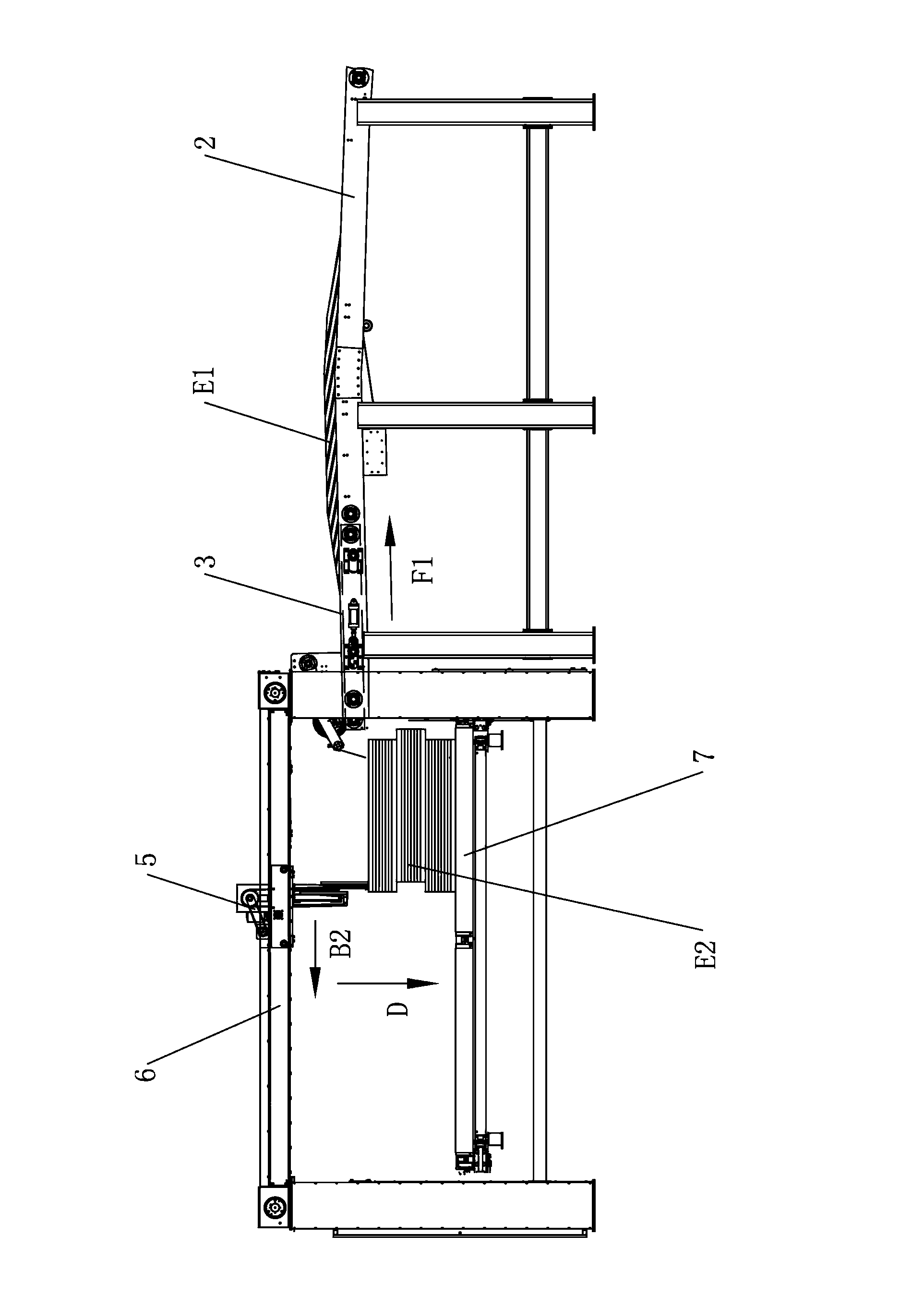

[0023] See figure 1 with figure 2 As shown, an automatic offset stacking device for cardboard includes a cardboard stacking mechanism 10 and a cardboard transfer mechanism 20. The cardboard transfer mechanism 20 is used to connect between the cardboard stacking mechanism 10 and cardboard production equipment (not shown). The mechanism 10 includes a liftable paper stacking table 7 with a conveyor belt; the cardboard conveying mechanism 20 includes a frame 2, a speed-increasing conveyor 3, an air cylinder 4, and a conveyor belt 1, and the speed-increasing conveyor 3 slides back and forth. At the front end of the frame 2, the conveyor belt 1 is arranged at the rear of the frame 2, the cylinder of the cylinder 4 is connected with the frame 2, and the piston rod of the cylinder 4 is connected with the speed-increasing conveyor 3.

[0024] The speed-increasing conveying device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com