Entire roll embossing production process of IML (in mould labeling) film

A production process and embossing technology, which is applied in the field of IML film embossing production process, can solve the problems of insufficient economic and practical value, low production efficiency and high cost, and achieve significant economic and practical value, saving manpower and material resources, and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

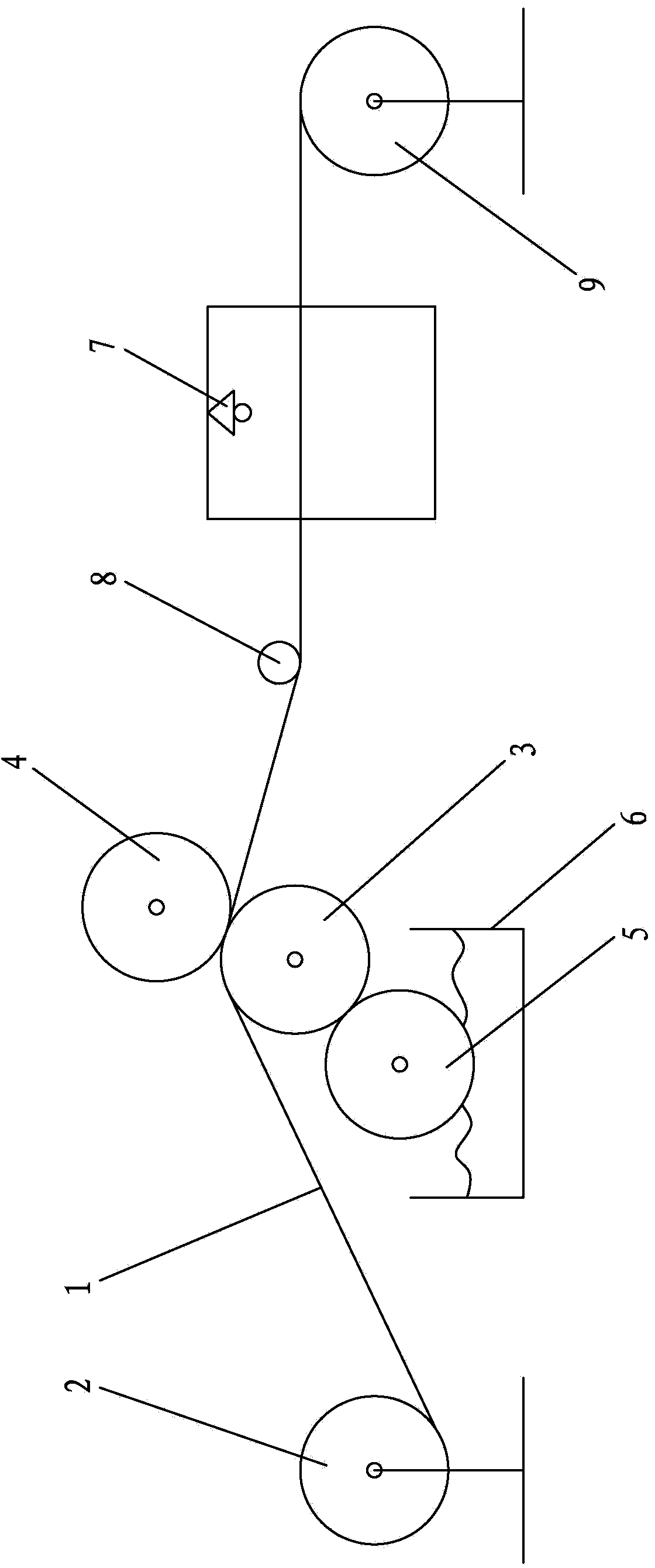

[0023] A kind of IML film roll embossing production technique of the present invention, as figure 1 As shown, on the basis of ensuring that the unwinding roller 2, the embossing roller 3, and the auxiliary pinch roller 4 are on the same assembly line, and that the film 1 is conveyed along this assembly line, the following steps are included:

[0024] (1) Unwind the embossed film 1 wound on the unwinding roller 2;

[0025] (2) Apply glue on the embossing roller 3 with patterns, and make the film 1 to be embossed pass through the embossing roller 3 and auxiliary clamping in such a way that the embossing roller 3 corresponds to the embossing surface of the film 1 to be embossed between the rollers 4, and make the embossing roller 3 and the auxiliary pinch roller 4 clamp the film 1 to be embossed to apply embossing pressure, the embossi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com