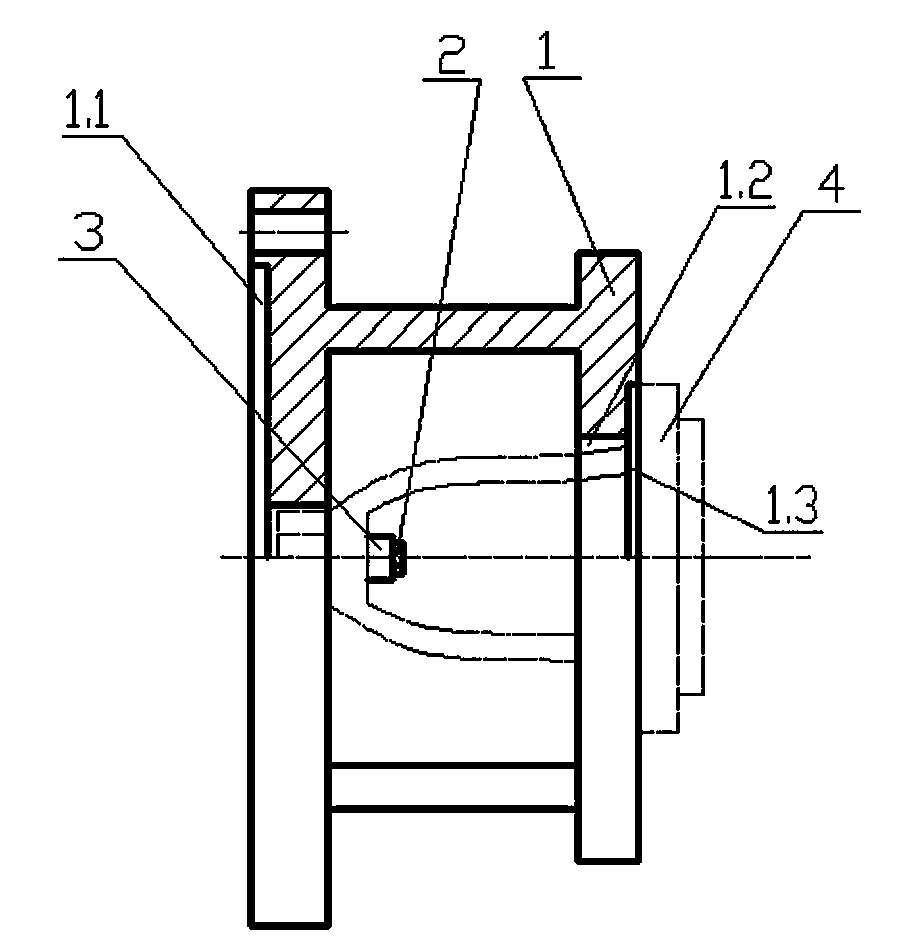

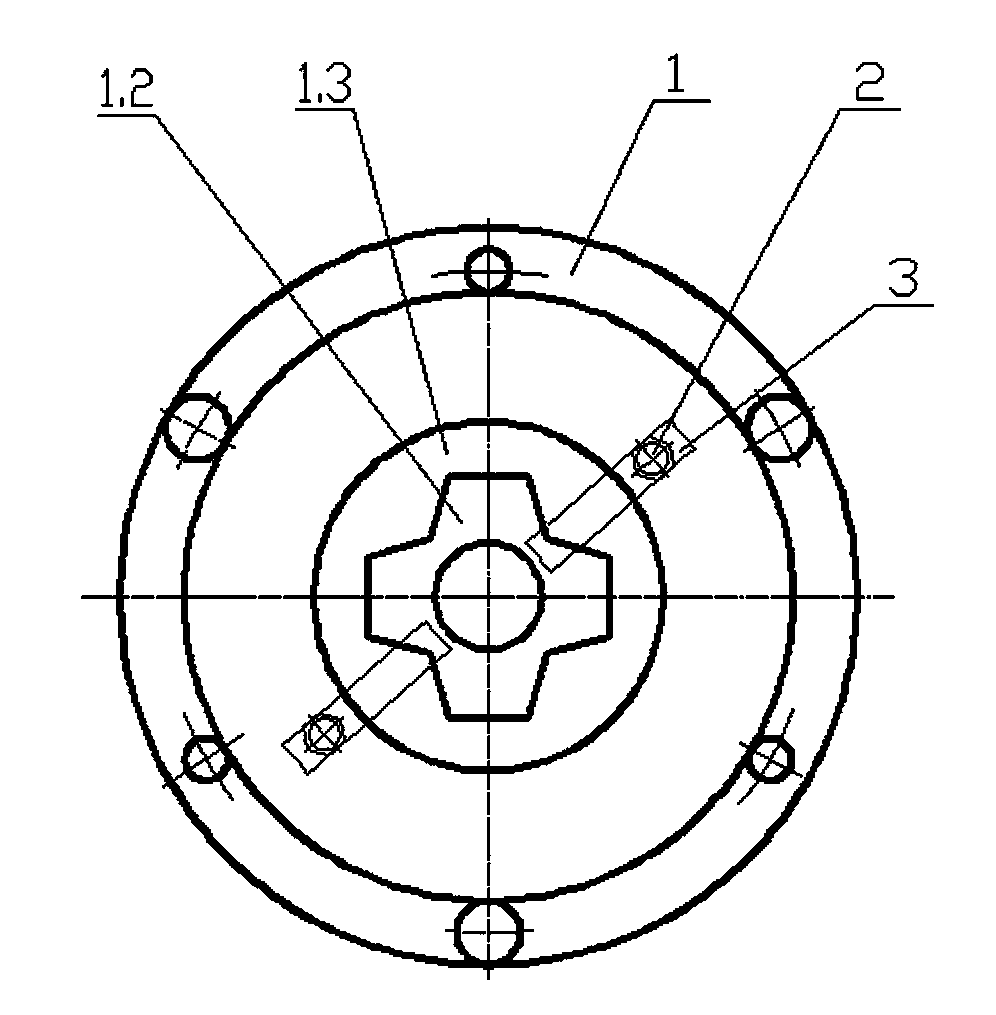

Locating and turning fixture for large end face and shaft hole of valve deck of stop valve

A large end face, positioning car technology, applied in the field of machining fixtures, can solve problems such as difficulty in meeting design requirements, and achieve the effects of reducing auxiliary man-hours, easy production, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

[0014] figure 1 The shown cut-off valve bonnet big end face and shaft hole positioning vehicle fixture, it is made up of clamp body 1, bolt 2 and pressure plate 3. The clamp body 1 is a double-layer conjoined disc frame with an inner hollow structure, and the left disc has an external end face seam 1.1, which is the positioning reference of the clamp body 1, and it is matched with the connecting plate of the supporting lathe. Co-located connections. There is a cross-shaped through hole 1.2 and a coaxial step hole 1.3 in the center of the end face of the right disc. The step hole 1.3 is the installation reference of the bonnet 4 to be processed, and the outer circle of the large end surface of the bonnet 4 to be processed is in clearance fit with the step hole 1.3. . The bolt 2 is installed on the inner end surface of the left disc, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com