Clamp of welding tool

A technology for welding tooling fixtures and connecting holes, which is applied in the mechanical field and can solve the problems of long time for tooling replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

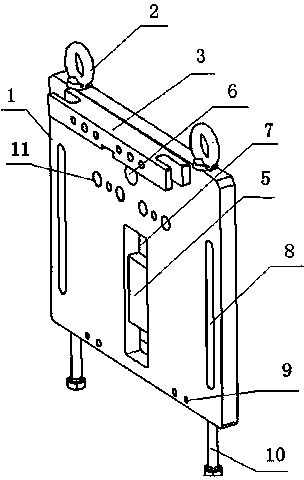

[0014] Such as figure 1 As shown, the fixture includes a positioning base plate 1, a positioning block I3, a positioning block II4, a positioning block III5, a lifting ring 2 and a bolt 10. The positioning base plate 1 is placed longitudinally, and two lifting rings 2 are connected to both sides of its top. The function of the lifting ring 2 is to lock the Quickly change the positioning base plate 1 to facilitate the use of steel wire ropes to pass through the ring for hoisting equipment when the device is moved.

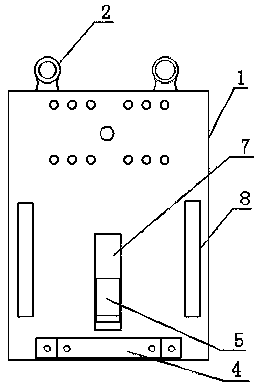

[0015] Such as figure 2 As shown, there are two strip-shaped holes on both sides of the plate surface of the positioning base plate 1, and a fixing hole 7 is opened in the middle of the plate surface, and the fixing hole 7 is used to connect the positioning block III5; The hole 11 is used to connect the positioning block I3; the bottom of the positioning base plate 1 is provided with a plurality of horizontal holes 9, and the holes 9 are used to connect the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com