Method for machining worm-gear pair

A worm gear, worm gear technology, applied in the direction of worm gear, worm, components with teeth, etc., can solve the problem that it is difficult for manufacturers to provide a wide variety of special worm gear hob.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

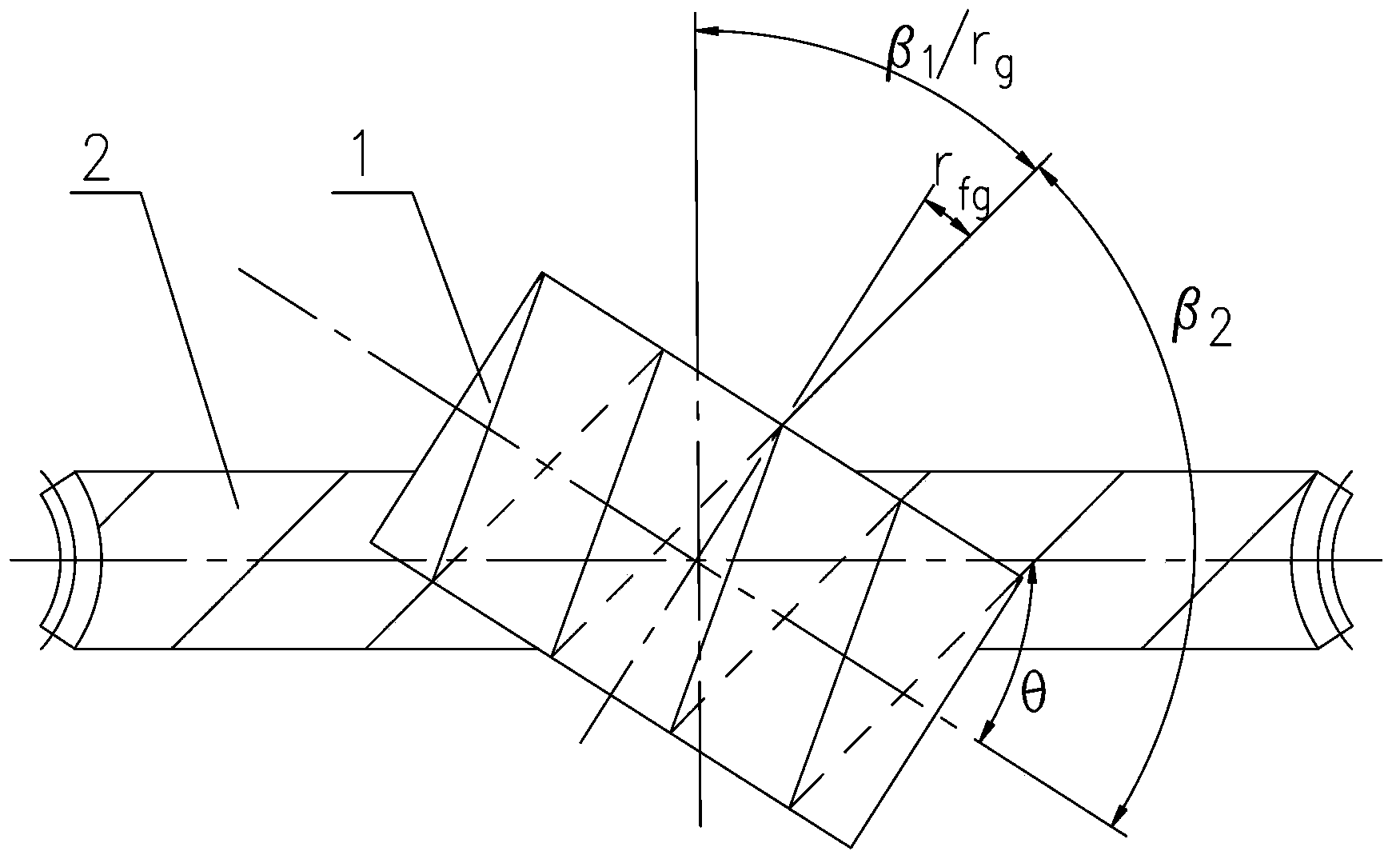

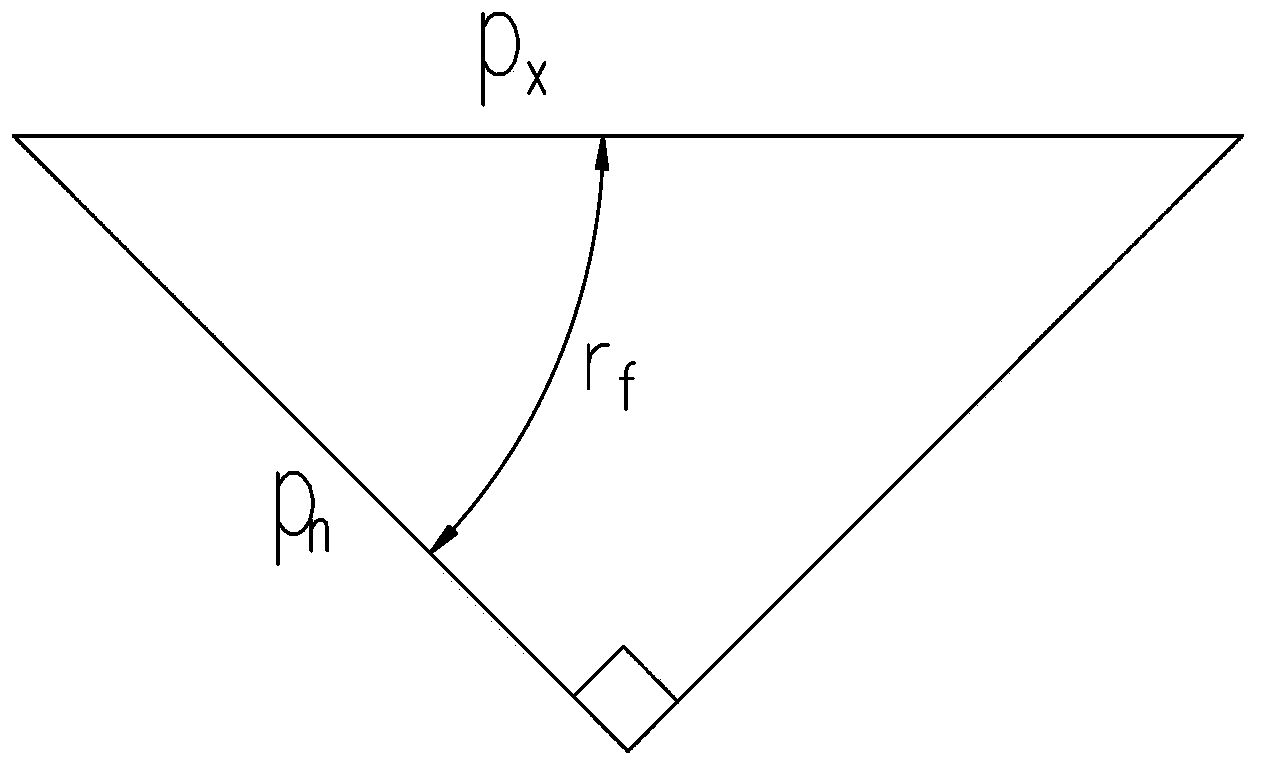

[0019] The technical solution for processing worm gears is based on the meshing principle of involute helical gears. According to this principle, to make the standard gear hob mesh with the processed worm gear, it must be ensured that the standard gear hob and the processed worm gear have a common normal modulus. Same as the pressure angle. To make the gear hob and the processed worm wheel have the same normal direction, the helix angles of the two must be complementary. Such as figure 1 In the case of machining a right-handed worm gear as shown, the helix angle β of the general standard gear hob 1 2 and the helix angle β of the worm wheel to be processed 1 Not complementary, and therefore no common normal. In order to make the gear hob 1 and the processed worm wheel 2 have a common normal direction, first place the end faces of the standard gear hob 1 and the processed worm wheel 2 perpendicular to each other, and keep the two radially connected, and the direction of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com