A bidirectional powder spreading device and powder spreading method for selective laser melting SLM equipment

A laser selective melting and powder spreading device technology, which is applied in the direction of improving process efficiency and energy efficiency, can solve the problems of increased demand for preset molding materials, long consumption time, and low powder supply, and achieve increased efficiency and The effect of qualified rate, shortened auxiliary process time, and reduced powder waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

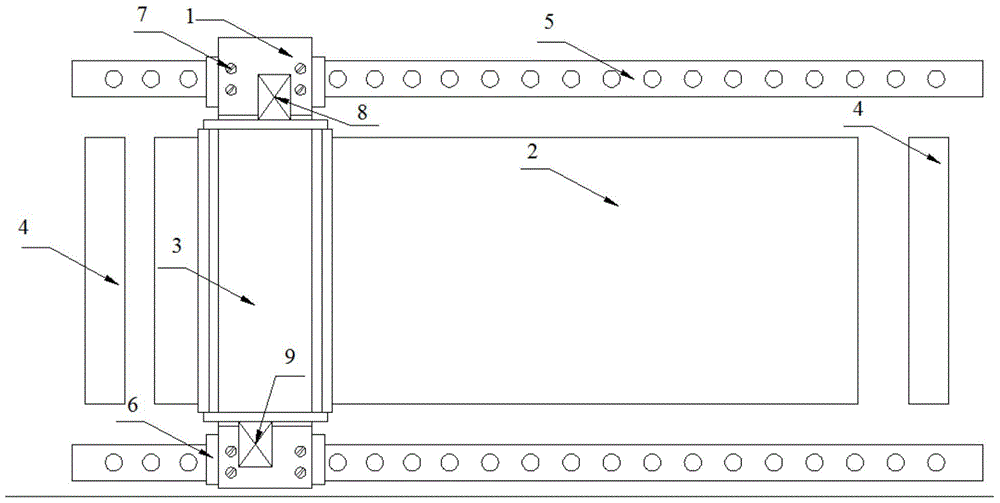

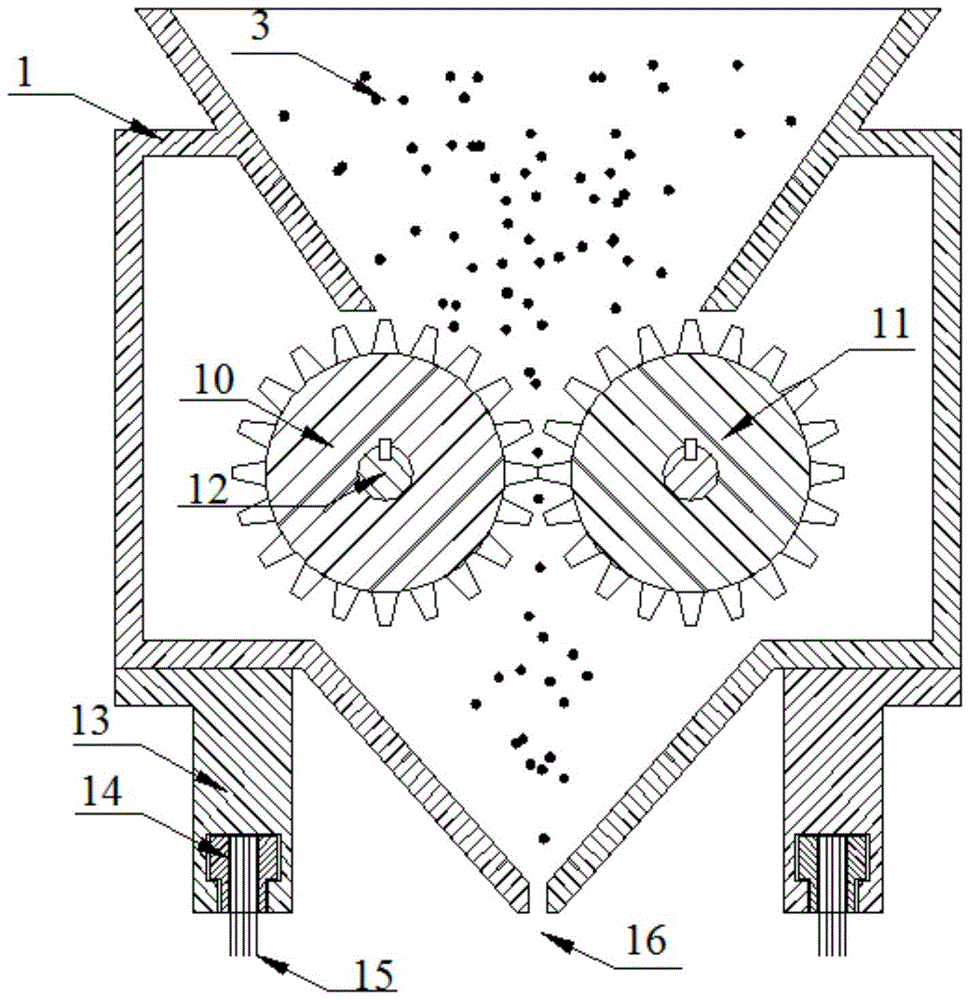

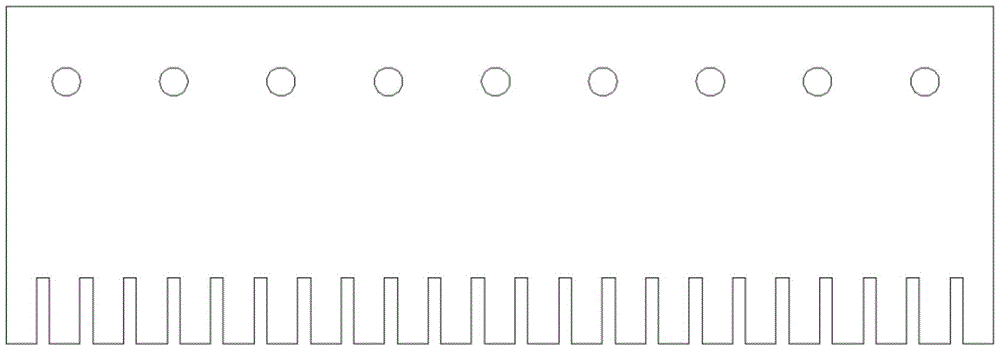

[0037] Such as figure 1 , figure 2 As shown, the two-way powder spreading device of the laser selective melting SLM equipment in this embodiment includes a main powder spreading device, two auxiliary linear motor guide rails 5 arranged in parallel, and a linear motor moving slider 6, and the linear motor moving slider is arranged on the auxiliary On the guide rail of the linear motor, the main powder spreading device is erected on the moving slider of the linear motor; the main powder spreading device includes a powder loading device 3 and two powder supply gears arranged in the powder loading device, that is, the first powder supply gear Gear 10 and the second powder supply gear 11, the first powder supply gear 10 and the second powder supply gear 11 are set at the same height, and the center of circle of the two powder supply gears is provided with a servo motor transmission shaft 12; when the servo motor is running, it drives The rotating shaft of the servo motor rotates,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com