Casting sand mold locking clamp

A technology of locking clamps and turning sand molds, applied in manufacturing tools, casting molding equipment, mold boxes, etc., can solve the problems of insufficient clamping degree of clamping clamps, inability to apply lateral casting, etc., to improve casting quality and simple structure. , the effect of avoiding accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

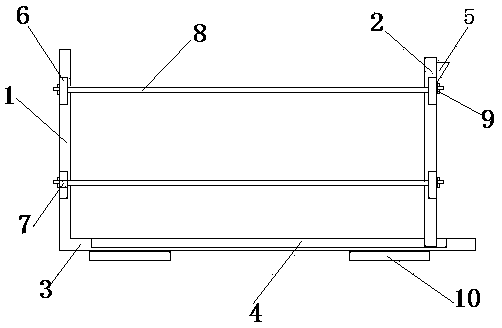

[0012] Examples such as figure 1 As shown, a casting foundry mold locking clamp includes a left clamping block 1, a right clamping block 2 and a locking device arranged between the two clamping blocks. The locking device includes a left clamping block 1, a right clamping The mounting block 6 on the side of the clamp block 2, the double-ended threaded connecting rod 8 penetrating through the through hole 7 of the mounting block 6, and the lock nuts 9 arranged at both ends of the double-ended threaded connecting rod 8, the locking device also includes A base 3 connecting the left clamping block 1 and the right clamping block 2, the left clamping block 1 is arranged on the left end of the base 3, and is integrated with the base 3; the right clamping block 2 is slidably arranged on the upper right part of the base 3 In the chute 4, the upper part of the right clamping block 2 is also provided with a liquid injection funnel 5.

[0013] The lower part of the base 3 is also fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com