Clamp for hydraulic pipe expansion and fin distributing method of clamp

A practical and fixture technology, which is applied in the field of hydraulic expansion tubes, can solve the problems of uneven wall thickness, low yield, and not tight riveting of aluminum tubes and fins, etc., and achieves the effect of convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

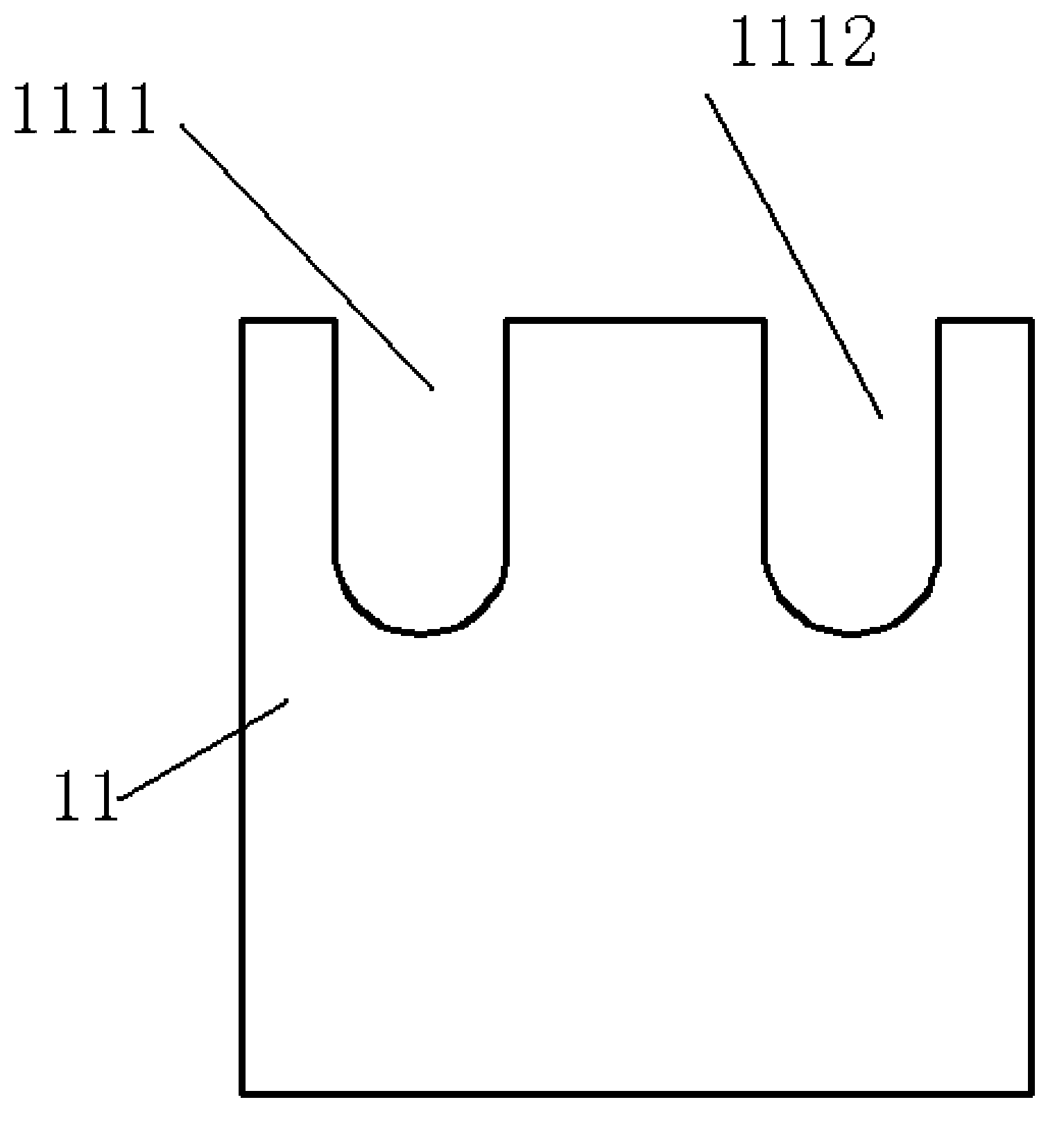

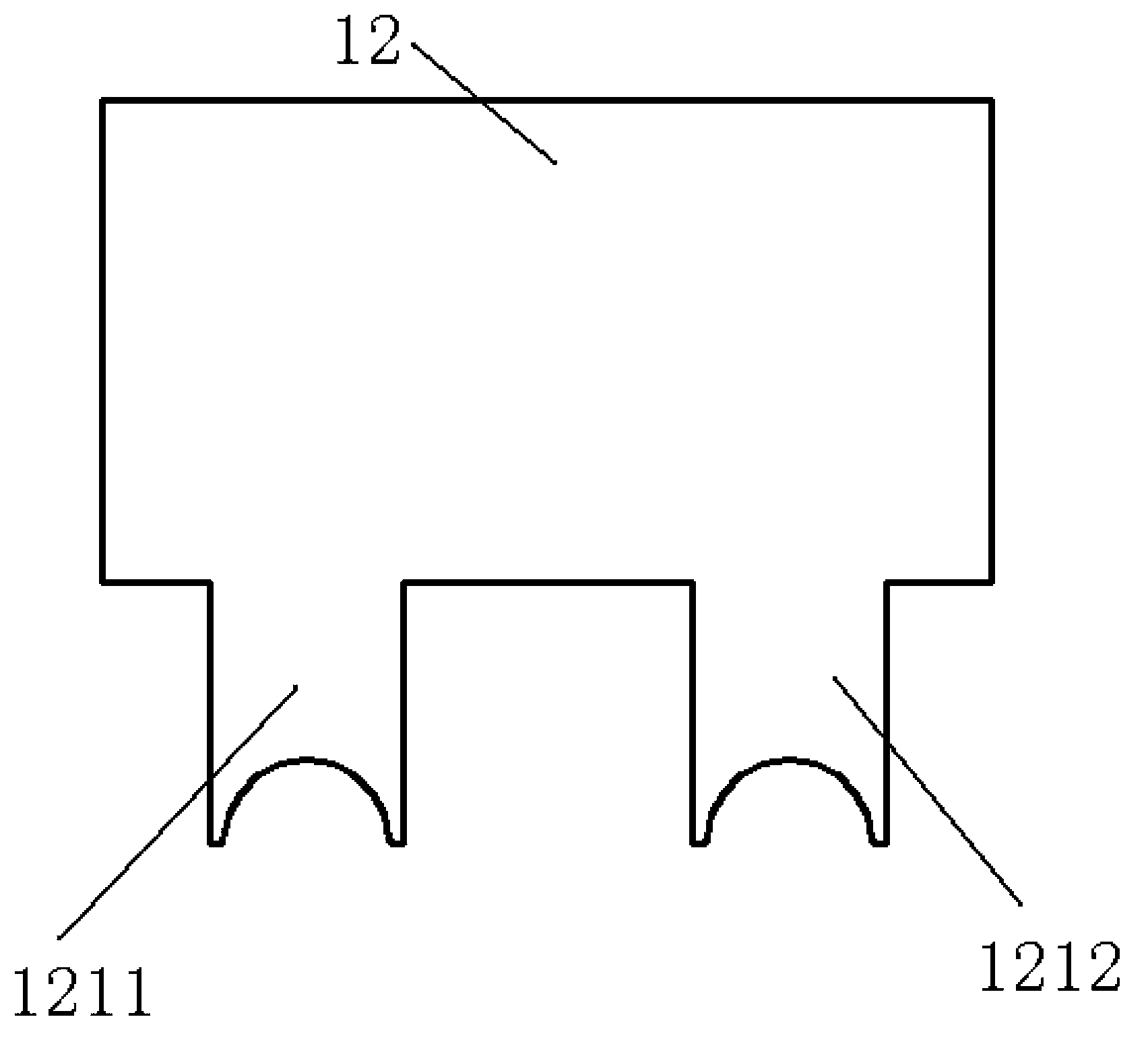

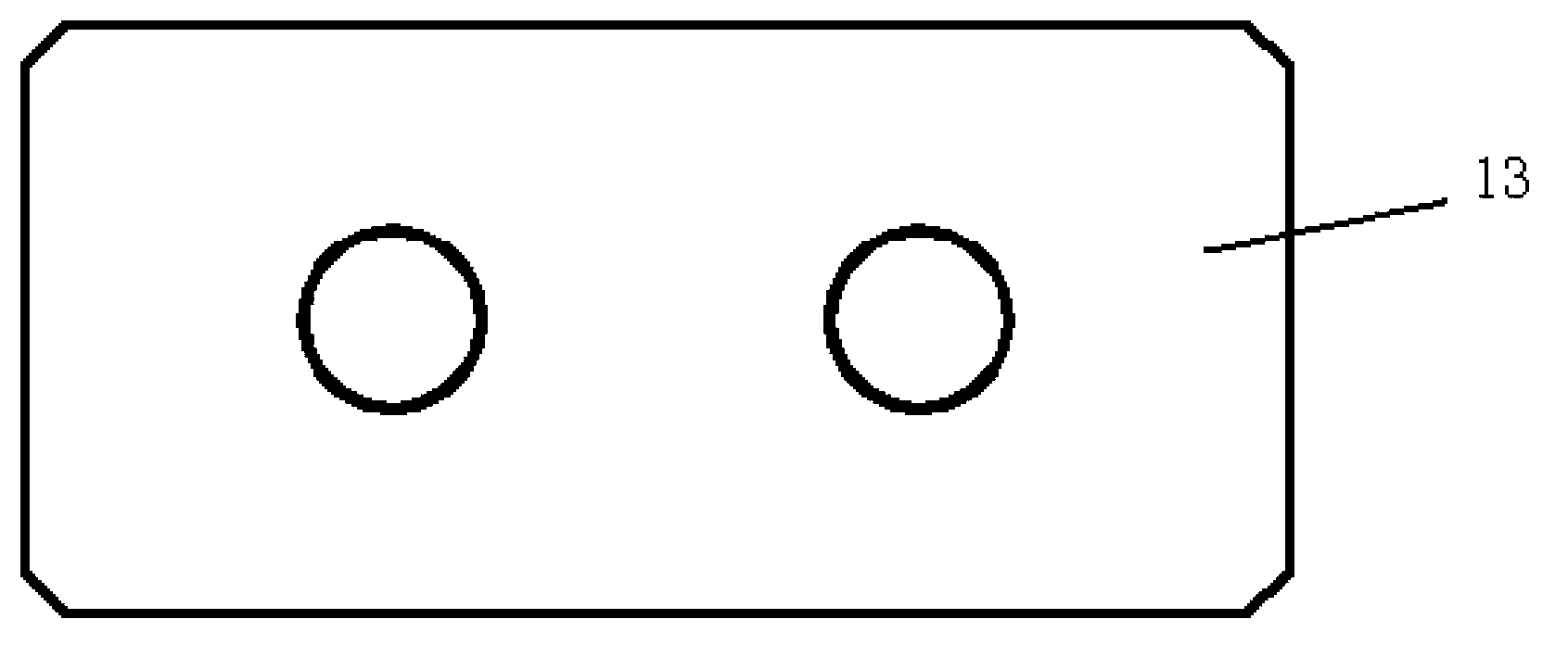

[0033] refer to Figure 1-5 As shown, the clamp for hydraulic pipe expansion includes a lower die 11 and an upper die 12 . Wherein the lower die 11 is provided with at least one "U"-shaped groove, and in this embodiment, two "U"-shaped grooves are selected, that is, the first groove 1111 and the second groove 1112, the first groove 1111 and the second groove. The two grooves 1112 have the same shape and are located on the same level. The distance between the first groove 1111 and the second groove 1112 matches the two holes 131 for inserting aluminum tubes in the fin. The first groove 1111 and the bottom of the second groove 1112 are both arc-shaped; the lower mold 11 is also provided with a plurality of slots 112 for discharging fins, wherein the slots 112 run through the side wall of the groove. The upper mold 12 is provided with at least one protrusion 121. In this embodiment, two protrusions matching the first groove 1111 and the second groove 1112 are selected, that is, ...

Embodiment 2

[0040] refer to Figure 6-7 As shown, the clamp for hydraulic expansion includes a lower die 21 and an upper die 22 . The lower die 21 is provided with at least one "U"-shaped groove 211. In this embodiment, one "U"-shaped groove 211 is selected. The bottoms of the grooves 211 are all arc-shaped. The diameters of the aluminum tubes are the same; the lower mold 21 is also provided with a plurality of slots 212 for fin discharge, wherein the slots 212 run through the side walls of the grooves 211 . The upper mold 22 is provided with at least one protrusion 221. In this embodiment, one protrusion 221 matching the above-mentioned groove 211 is selected. An approximate circle is formed, and the diameter of the approximate circle is the same as that of the expanded aluminum tube, which is used to protect the aluminum tube from expanding within a fixed range, so as not to cause rupture due to involuntary expansion.

[0041] Refer to Example 1 for the sheet arranging method using th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com