Wheat flour production system

A production system and technology for wheat flour, applied in grain processing and other directions, can solve the problems of low production efficiency, low flour quality, backward production equipment, etc., and achieve the effects of high production efficiency, high purity and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

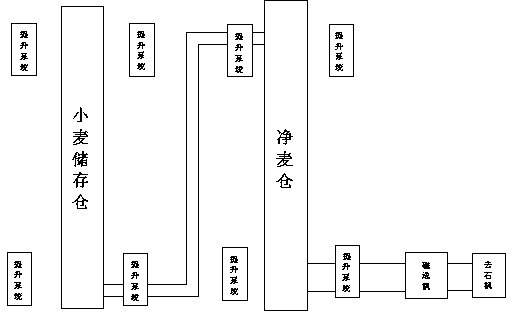

[0009] The specific embodiment of the present invention is illustrated below: a wheat flour production system, comprising a wheat storage bin, a wheat cleaning bin, a lifting system, a wheat washing system, a magnetic separator, a destoner, a humidity adjustment system, a high-pressure air supply system, a mill Flour machine, auger conveying system and packaging machine, wheat storage bin and clean wheat bin are all upright cylindrical, the upper and lower ends of the wheat storage bin and clean wheat bin are equipped with multiple lifting systems for transporting wheat, the wheat washing system will The wheat in the wheat storage bin is washed and sent to the clean wheat bin, which is connected with the magnetic separator, de-stoner, and humidity adjustment system in turn, and the high-pressure air supply system provides power to send the wheat in the clean wheat bin to the mill. The machine and the mill are connected with the auger conveying system and the packaging machine i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com