Wiper blade with an adaptor unit for coupling to a wiper arm

A wiper arm and wiper blade technology, which is applied in vehicle cleaning, vehicle maintenance, transportation and packaging, etc. It can solve problems such as connections are no longer fastened enough, wiper blades are loosened, broken, etc., and the structural size is achieved The effect of small, inexpensive, strong and robust connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

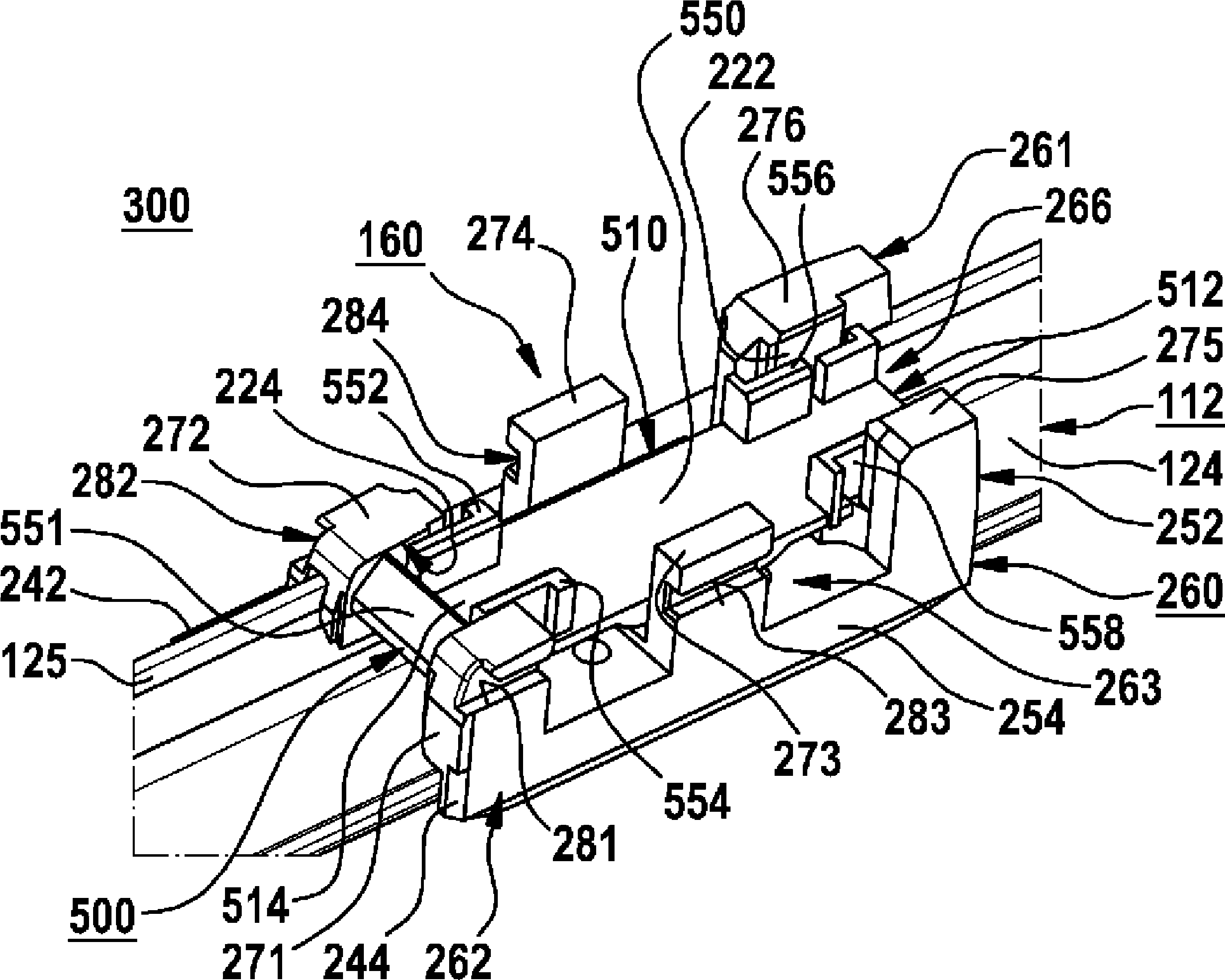

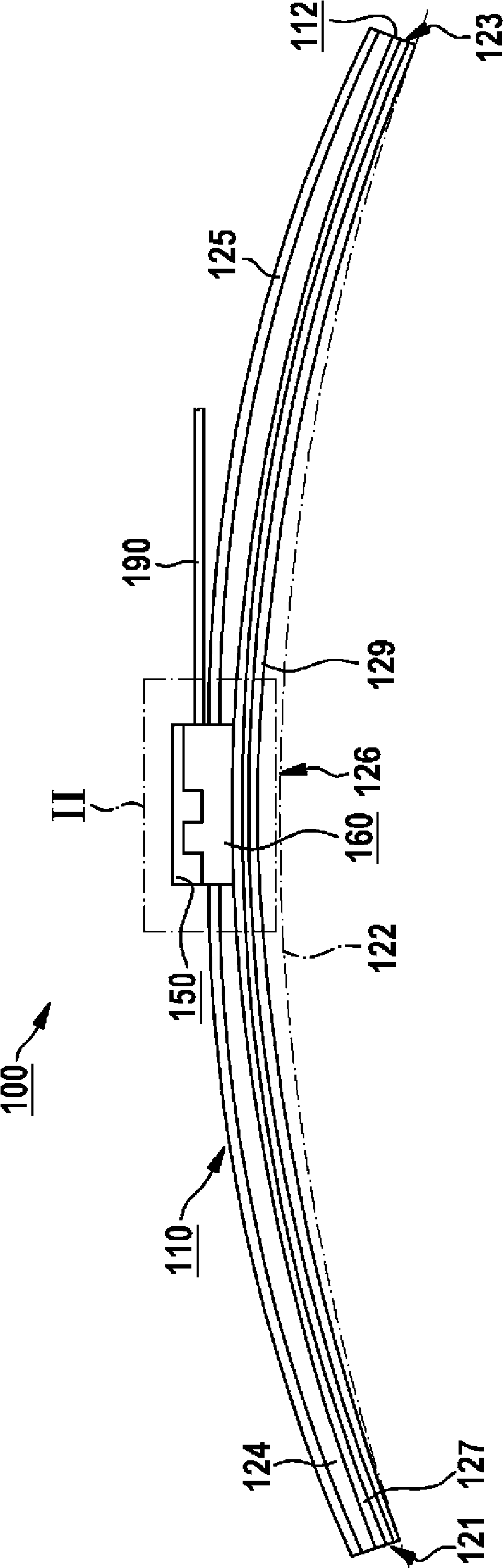

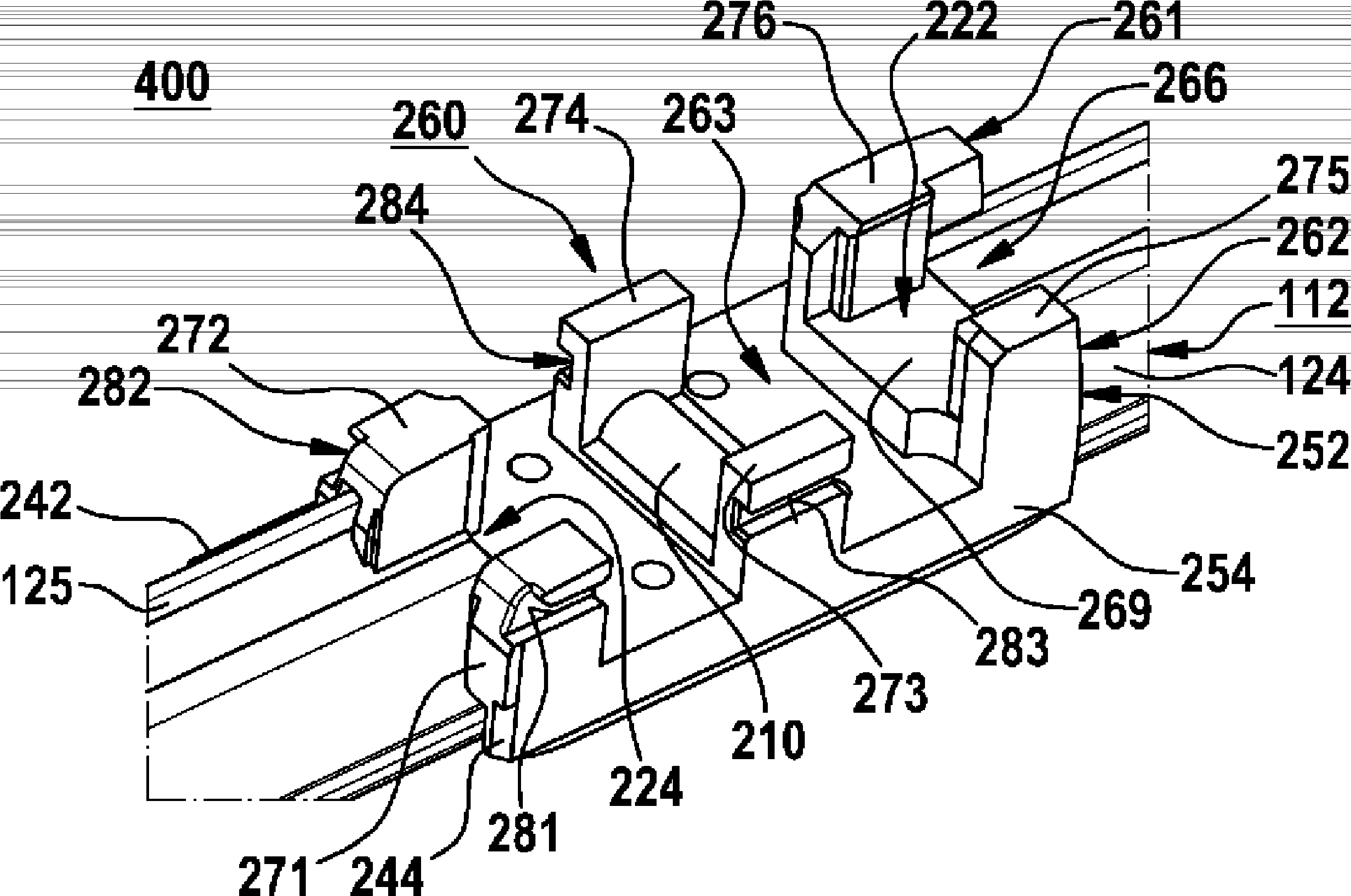

[0034] According to one specific embodiment, the wiper blade 110 is designed as a flat beam, ie the wiper strip 112 has a lateral longitudinal groove, which is formed, for example, on the back strip 124 and in which two are arranged. Carrier rails, preferably spring rails. As an alternative thereto, the wiper strip 112 can be designed as a hollow profile with an approximately central longitudinal channel, for example arranged in the rear web 124 , in which a single carrier rail is arranged.

[0035] Attached to the wiper strip 112 is an adapter unit 160 , which is covered by an optional cover-shaped fastening means 150 , and which is used to articulate the wiper strip 112 on a wiper arm 190 , by means of which The wiper arm can guide the wiper blade 110 for wiping a window 122 shown in dashed lines, for example a motor vehicle window. The fastening cover 150 is therefore optional, since the use of the fastening cover 150 can be dispensed with when the adapter unit 160 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com