Field grading detection method and system for postharvest apples based on embedded technology

A detection method and apple technology, applied in measurement devices, optical devices, character and pattern recognition, etc., can solve the problems of not easy to carry, economic loss, and inability to popularize the post-harvest pre-sorting technology of apples.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The development process of this system will be further described below in conjunction with the specific drawings.

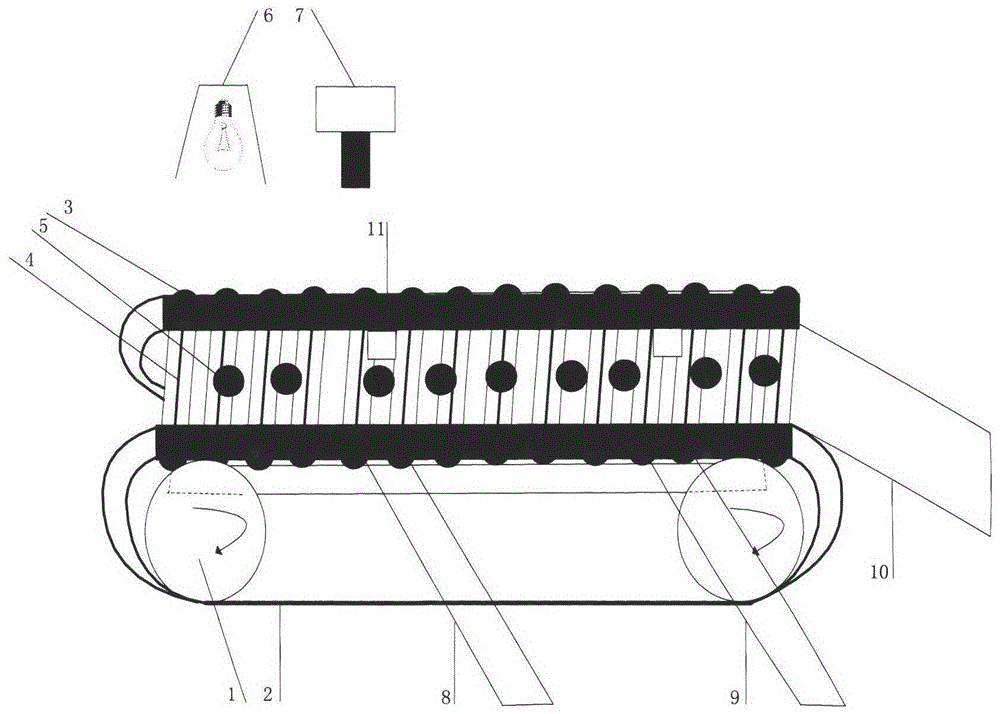

[0060] The detection system completes the image acquisition, processing and analysis, and separation of each apple during the apple conveying movement. figure 1 It is a schematic diagram of the system. Two groups of chain conveyor belts 2 with the same structure are installed side by side, driven by sprocket 1, and the conveyor belt drives roller 3 and roller 4 to move. The apple rolls forward on the conveying platform, and the camera can capture 90% of the apple. % above epidermis image. In order to reduce the influence of light, all apples are detected under the same light source 6, and the CMOS camera 7 is installed vertically above the conveyor belt to collect the target image on the conveyor belt in real time, and the processor identifies and grades the collected images, and The grading results are sent to the implementing agency 11 to perform the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com