Step-by-step deep profile control method based on pressure field and flow velocity field distribution

A technology of deep profile control and flow velocity field, which is applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc. It can solve the problems of large differences and insufficient consideration of the influence and combination of flow velocity on the performance of profile control agents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The experimental methods used in the following examples are conventional methods unless otherwise specified.

[0020] The materials and reagents used in the following examples can be obtained from commercial sources unless otherwise specified.

[0021] Assumption conditions: homogeneous horizontal infinite formation, permeability K, fluid viscosity μ.

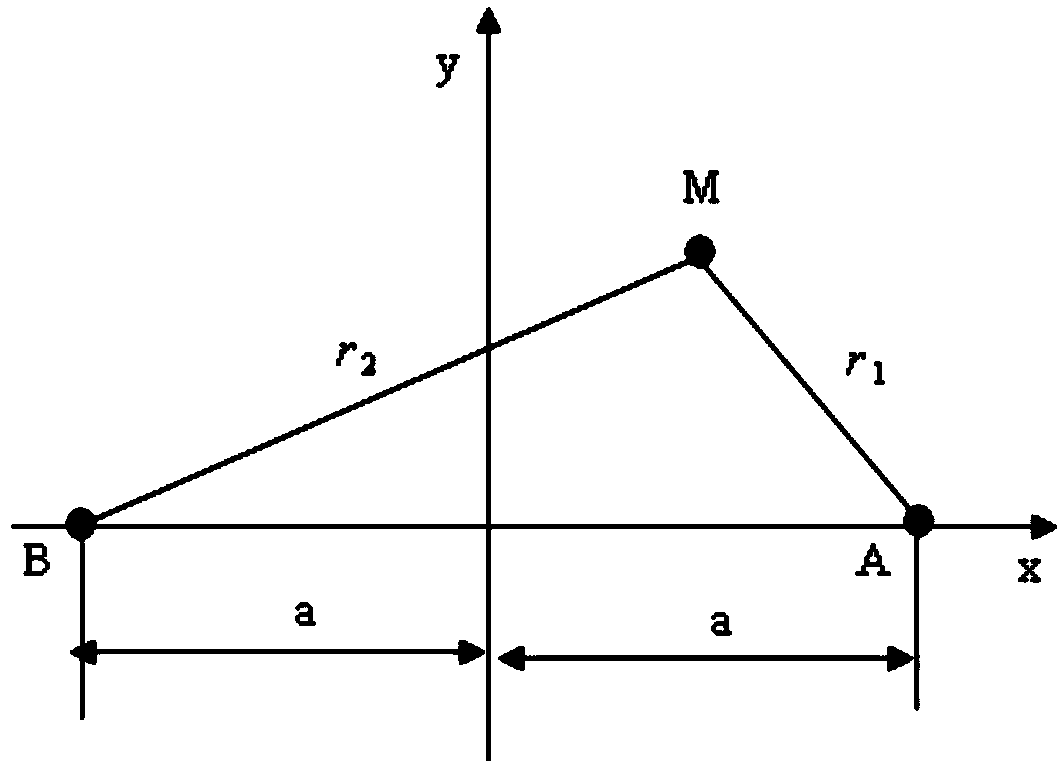

[0022] One production well A, one water injection well B, the well spacing is 2a, and the wellbore radius is R w , the injection well pressure is P 注 . The injection volume per unit thickness of the water injection well is q, and the production volume per unit thickness of the production well is q. At any point M in the formation, the distance to the production well A is r 1 , the distance to the injection well is r 2 , through physical simulation experiments, the optimal injection depth obtained is r 0 , the schematic diagram is as figure 1 .

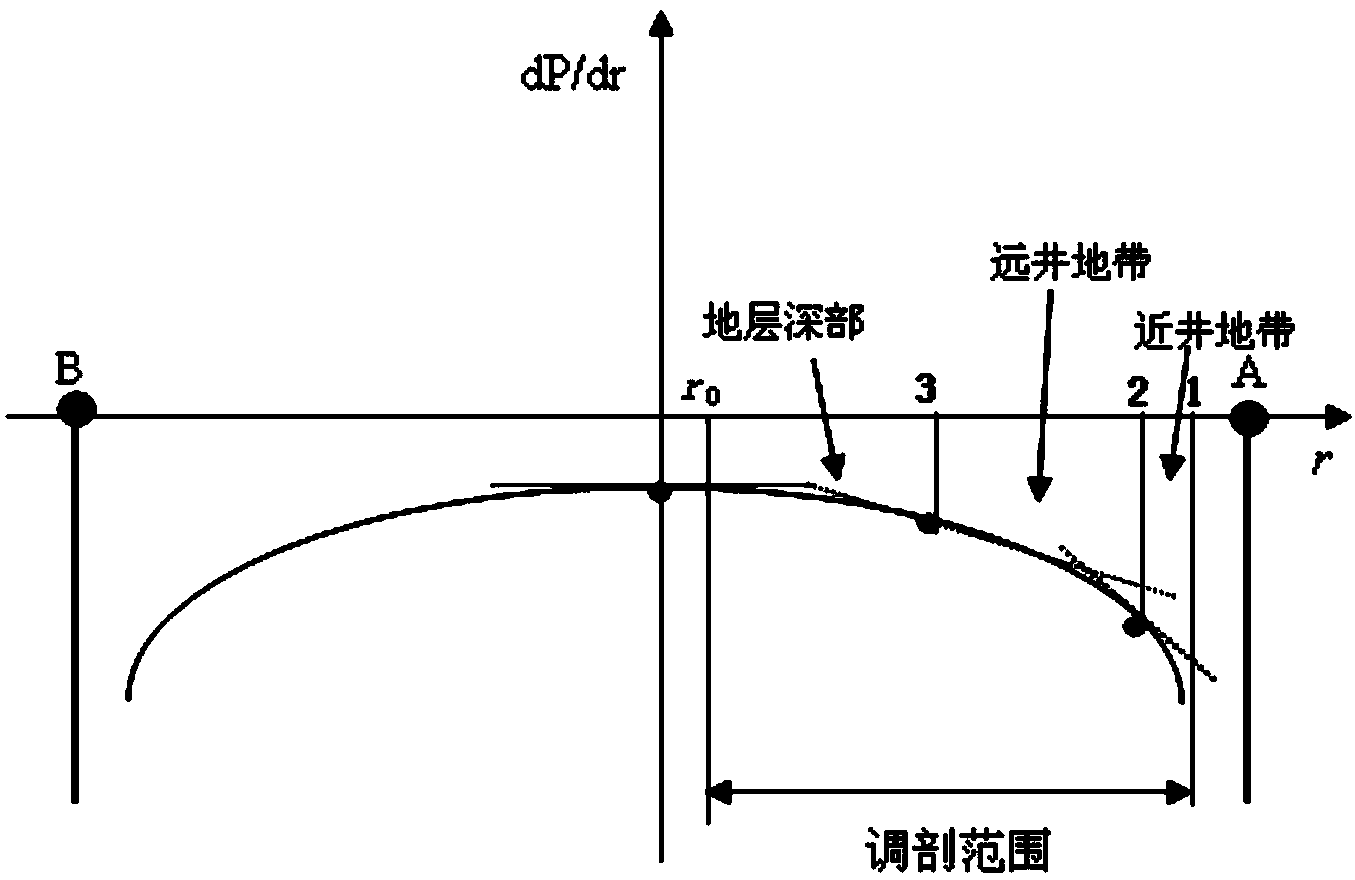

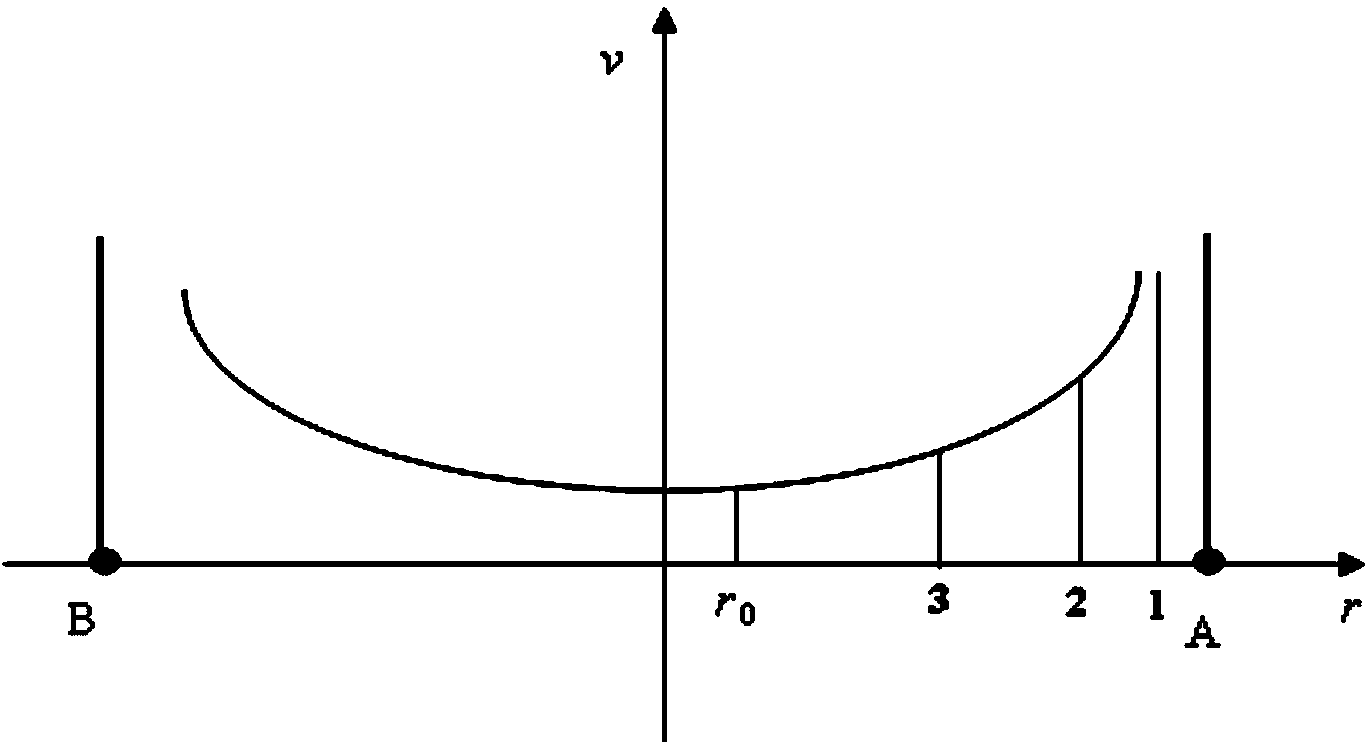

[0023] Generally, the range of profile control refers to the distanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com