Bow blowing spherical joint of dredging ship

A technology of ball joints and dredgers, which is applied in the direction of earth movers/shovels, construction, etc., can solve the problems of joint failure, accelerated wear of parts, and easy entry of sand, so as to prevent seawater or sand from entering and ensure Lubrication, the effect of speeding up disassembly and assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

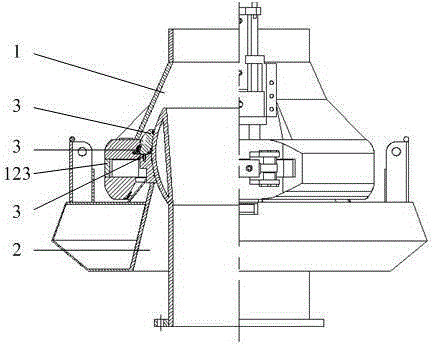

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

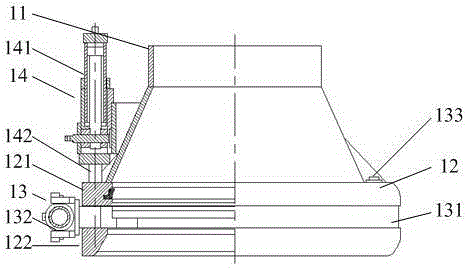

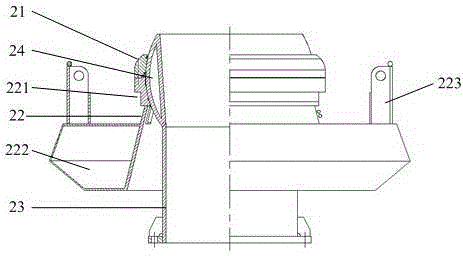

[0024] Such as Figure 1-Figure 3 As shown, the embodiment of the present invention provides a dredger bow blowing ball joint, including a female head 1 and a male head 2 that are mated and connected to each other. The female head 1 includes a connecting pipe 11, and the bottom of the connecting pipe 11 is connected to the female sleeve head. 12 connection, the female sleeve 12 is provided with a locking device 13 for locking the male head 2; the male head 2 includes an upper cover 21, a lower cover 22 and a sphere connecting pipe 23, and the sphere connecting pipe 23 is provided Between the upper cover 21 and the lower cover 22, a spherical turning part 24 is arranged on its upper part, and the inner walls of the upper cover 21 and the lower cover 22 are circular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com