Cake discharge protective structure of spiral oil press

A protective structure and oil press technology, applied in presses, manufacturing tools, etc., can solve the problems of high pressure in the press chamber, injury of on-site personnel, and no protection, etc., to reduce environmental pollution, improve the working environment, and reduce resources wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

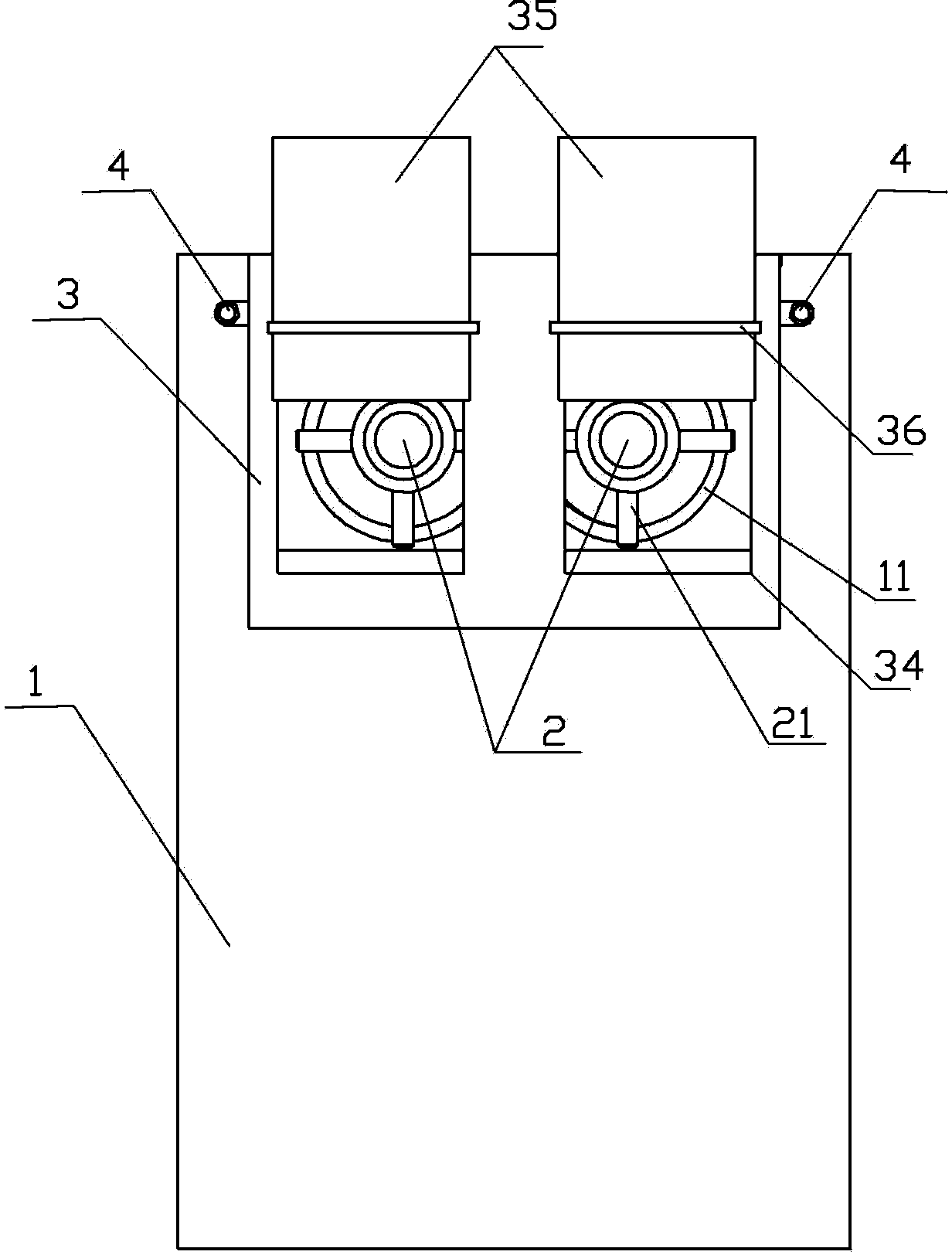

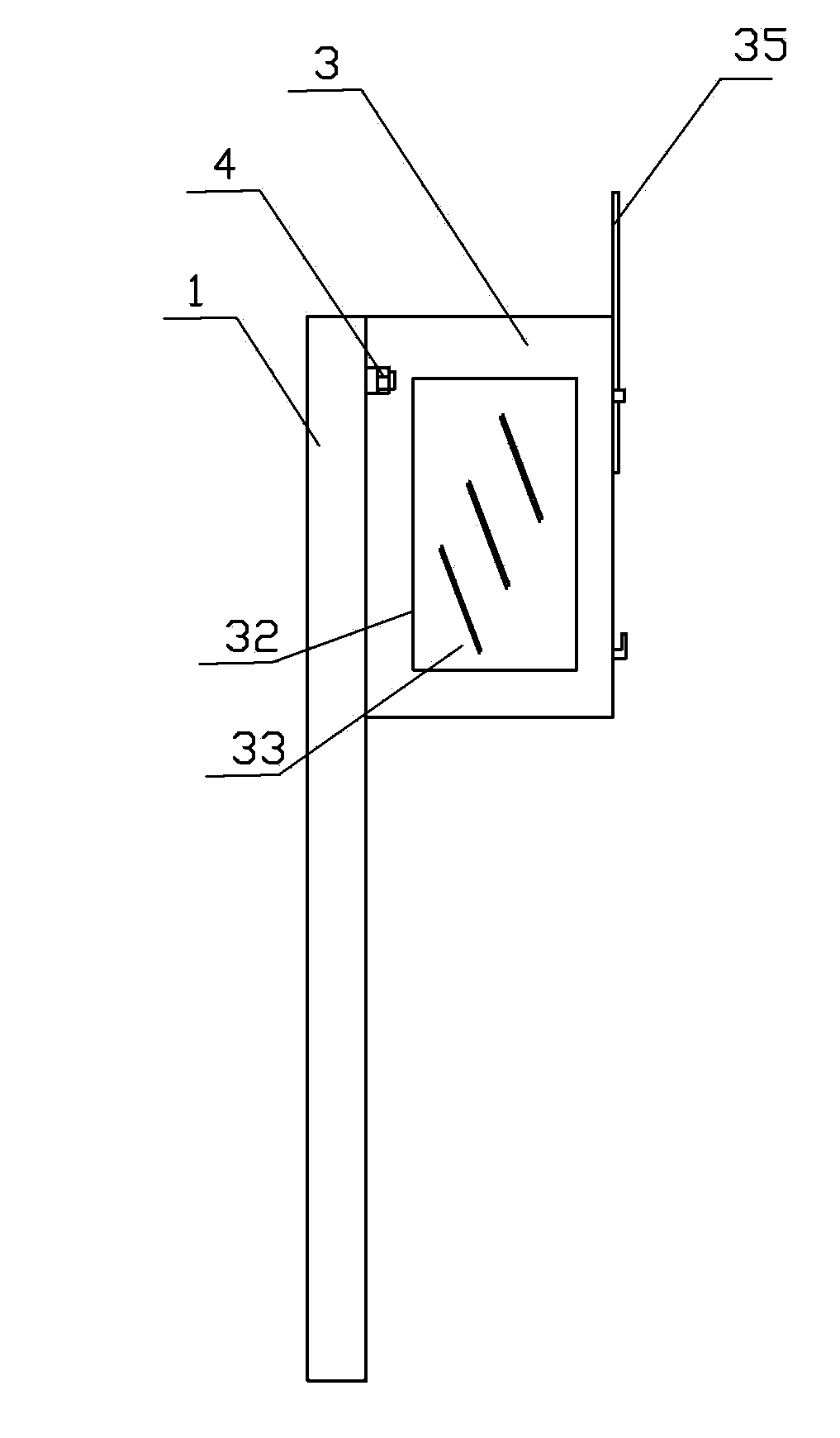

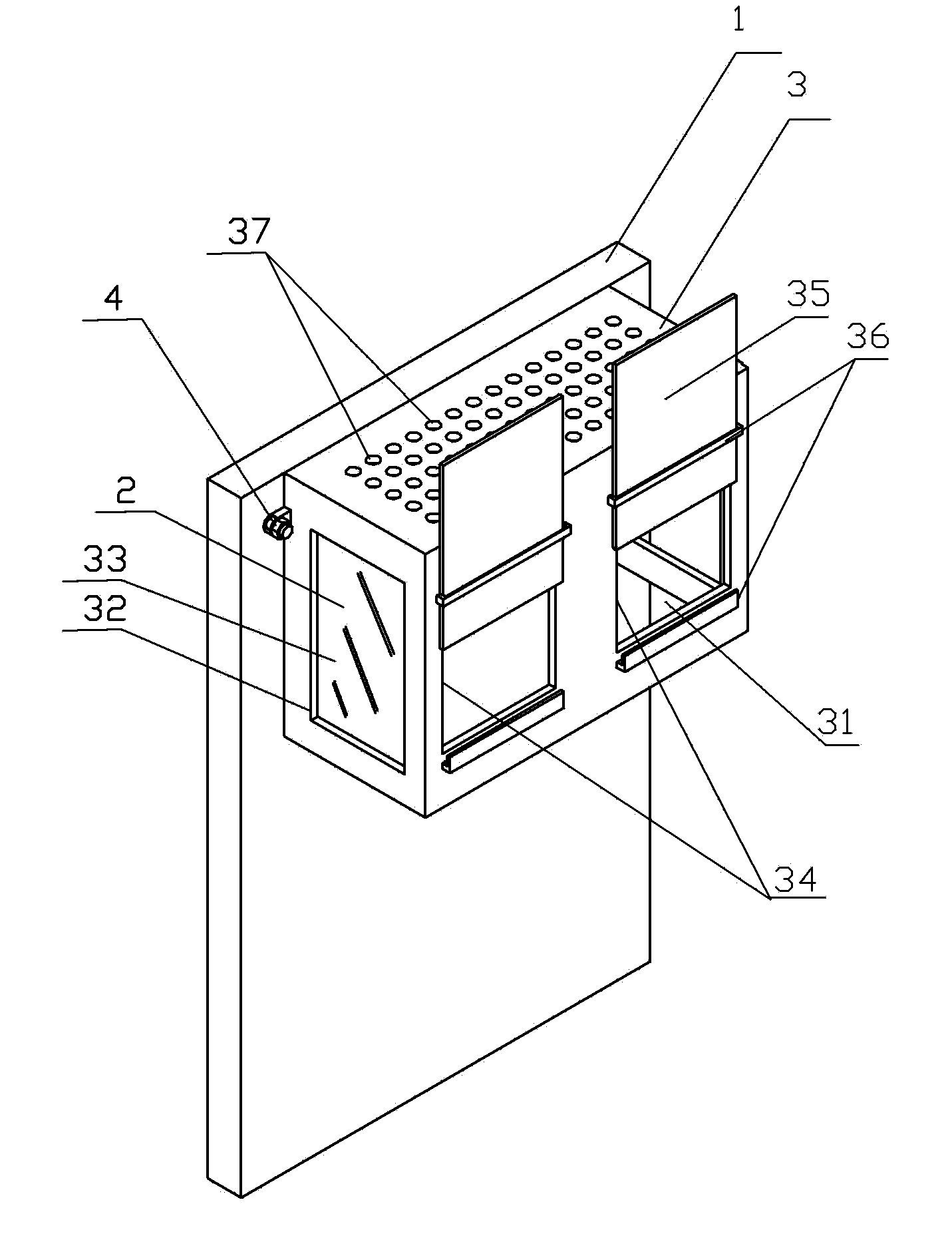

[0025] Such as Figure 2-3 Shown: a cake output protection structure for a screw oil press, which includes a rear end plate 1, a screw shaft 2 and a protective device; There is a cake outlet hole 11 between them (the figure shows a double-screw shaft oil press, and it can also be a single-screw shaft oil press), and the pressed oil cake will be discharged from the cake outlet 11 (the screw shaft 2 and the rear Gap drain on end plate 1).

[0026] Protective device comprises protective cover 3, and protective cover 3 is a cover shape body, can be plastics or iron material, but preferably stainless steel is made, and heat resistance is good on the one hand, intensity is good, not easily deformed, is not easily damaged by oil cake, on the other hand On the one hand, it is not easy to rust and easy to clean. The protective cover 3 is fixedly installed on the rear end plate 1 by bolts or locks and is located at the position of the cake outlet hole 11, which can cover the part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com