Composite material laying compression roller with laminating-type rubber covered roller structure

A technology of composite materials and rubber rollers, which is applied in the field of aviation-specific automatic tape laying equipment, can solve the problems of single procurement channels, high prices, and short service life, and achieve the effects of reducing manufacturing costs, ensuring surface characteristics, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

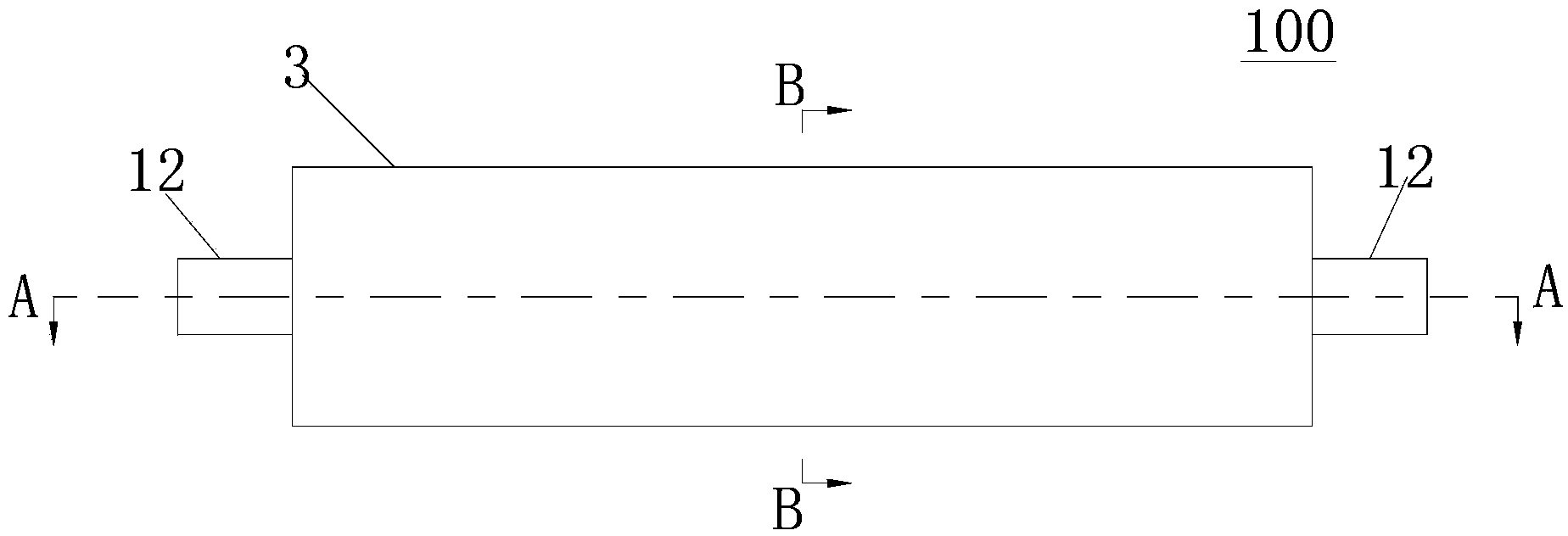

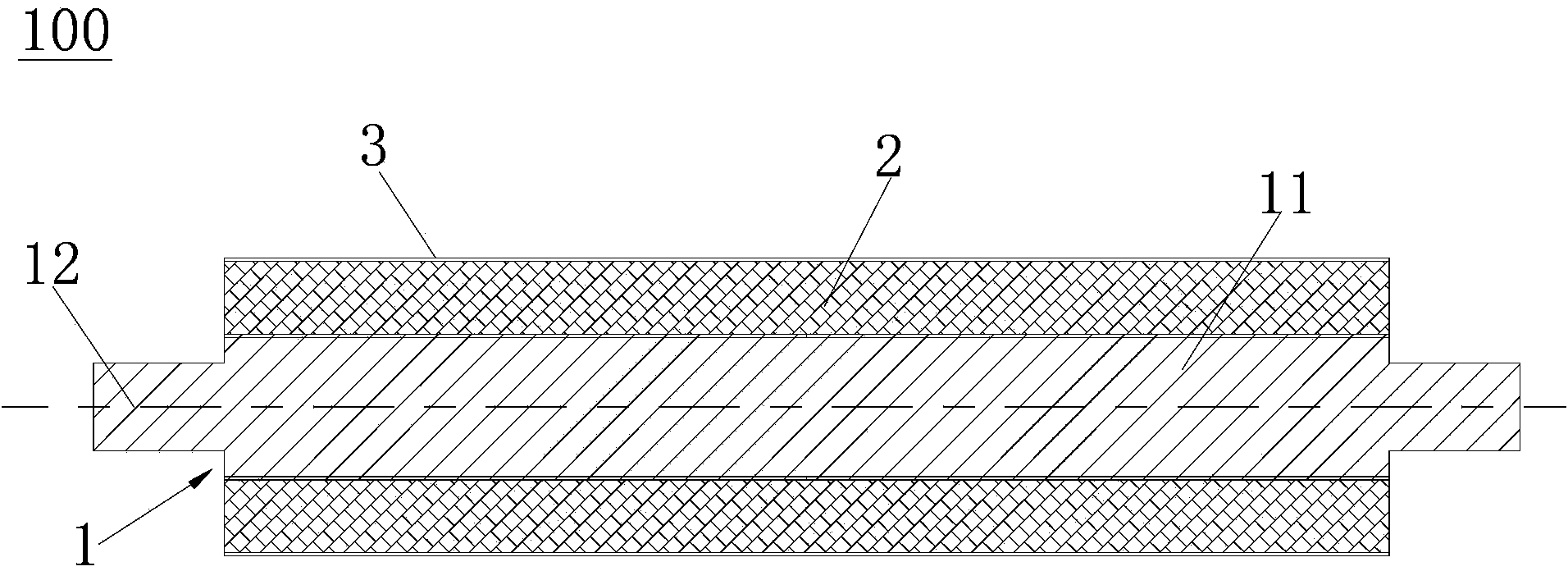

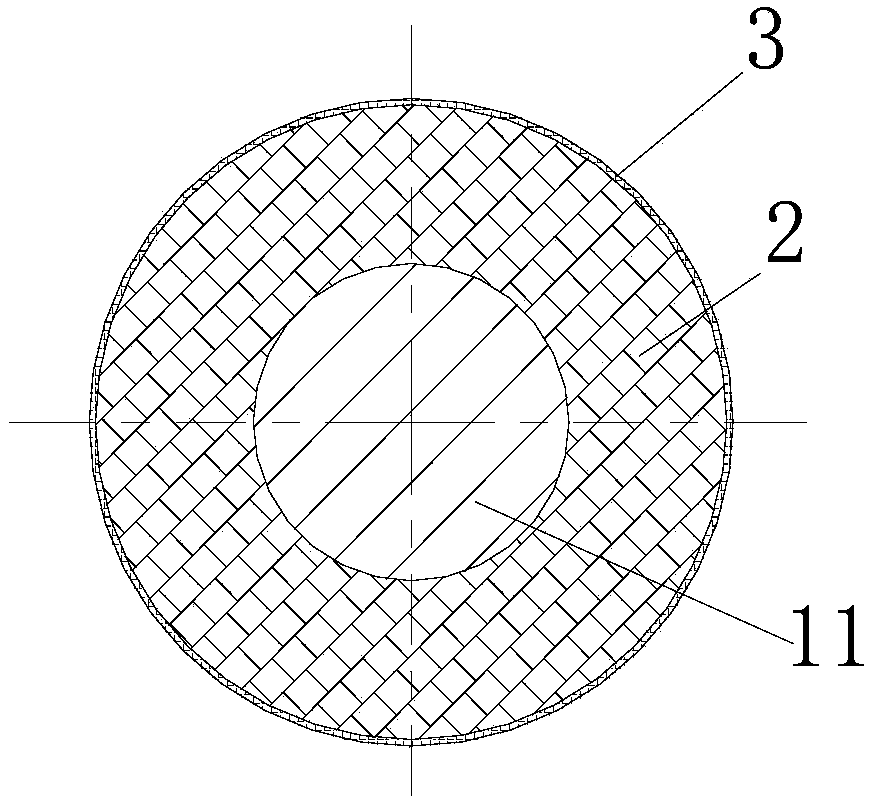

[0026] The invention provides a composite material laying pressure roller with a film-coated rubber roller structure. The metal mandrel includes a cylindrical mandrel body part and two bearing support parts correspondingly arranged at both ends of the mandrel body part. , the bearing support part is arranged coaxially with the mandrel body part, and its outer diameter is smaller than the outer diameter of the mandrel body part, wherein the outer surface of the mandrel body part is covered with an elastic rubber layer, The outside of the elastic rubber layer is covered with a roller surface rubber layer.

[0027] The composite material laying roller with film-coated rubber roller structure of the present invention is convenient for processing and manufacturing, prolongs the service life of the composite material laying roller, improves the maintainability of the composite material laying roller, and reduces the cost of composite material laying. The manufacturing cost of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com