Device for performing double curvature sheet bending and forming by utilizing electronic universal testing machine

A universal testing machine and bending forming technology, which is applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems that the double curvature parts are difficult to ensure the curvature accuracy requirements of the formed parts, so as to improve the forming accuracy, ensure the forming accuracy, avoid Effect of multiple disassembly and commissioning procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

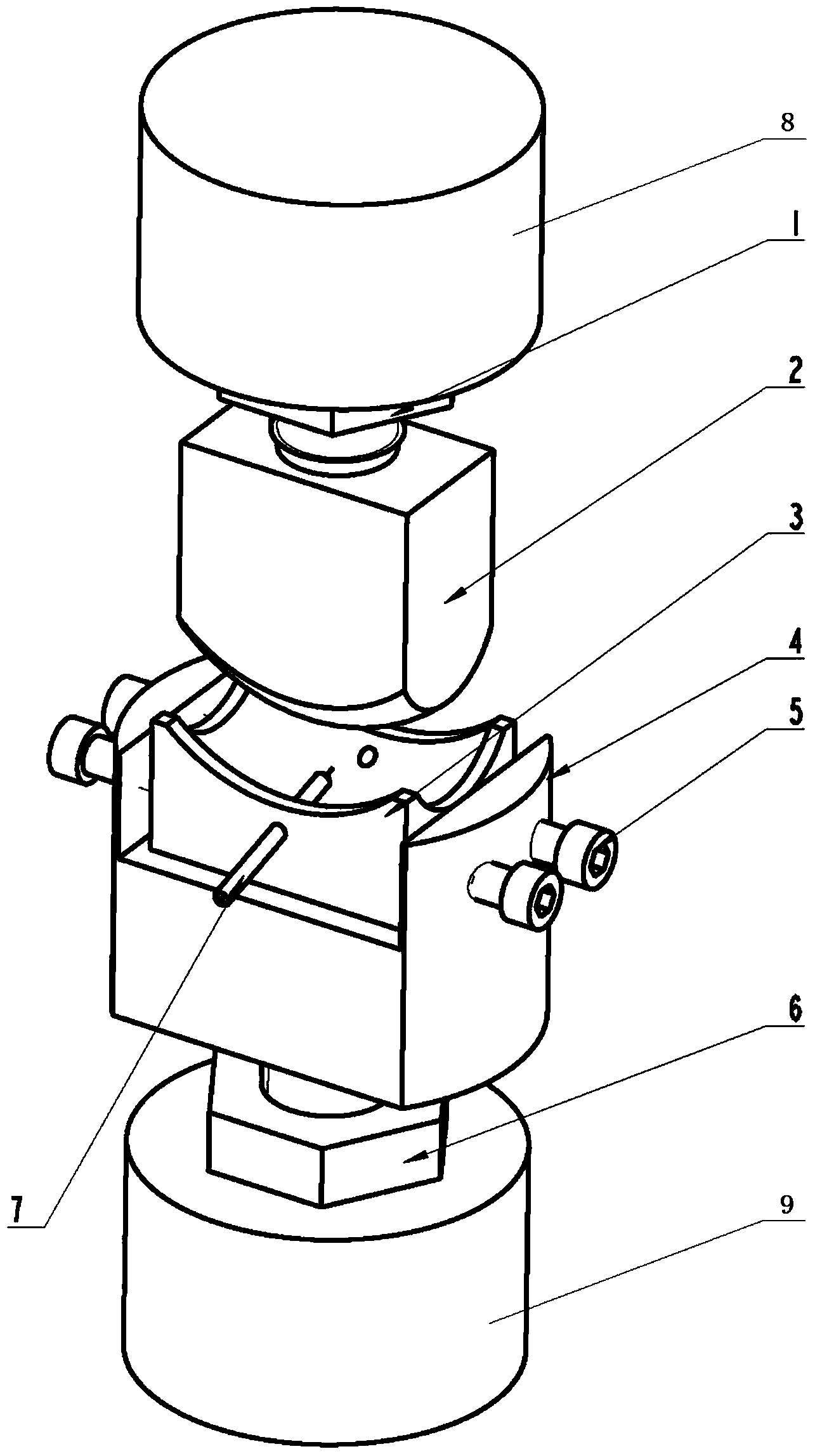

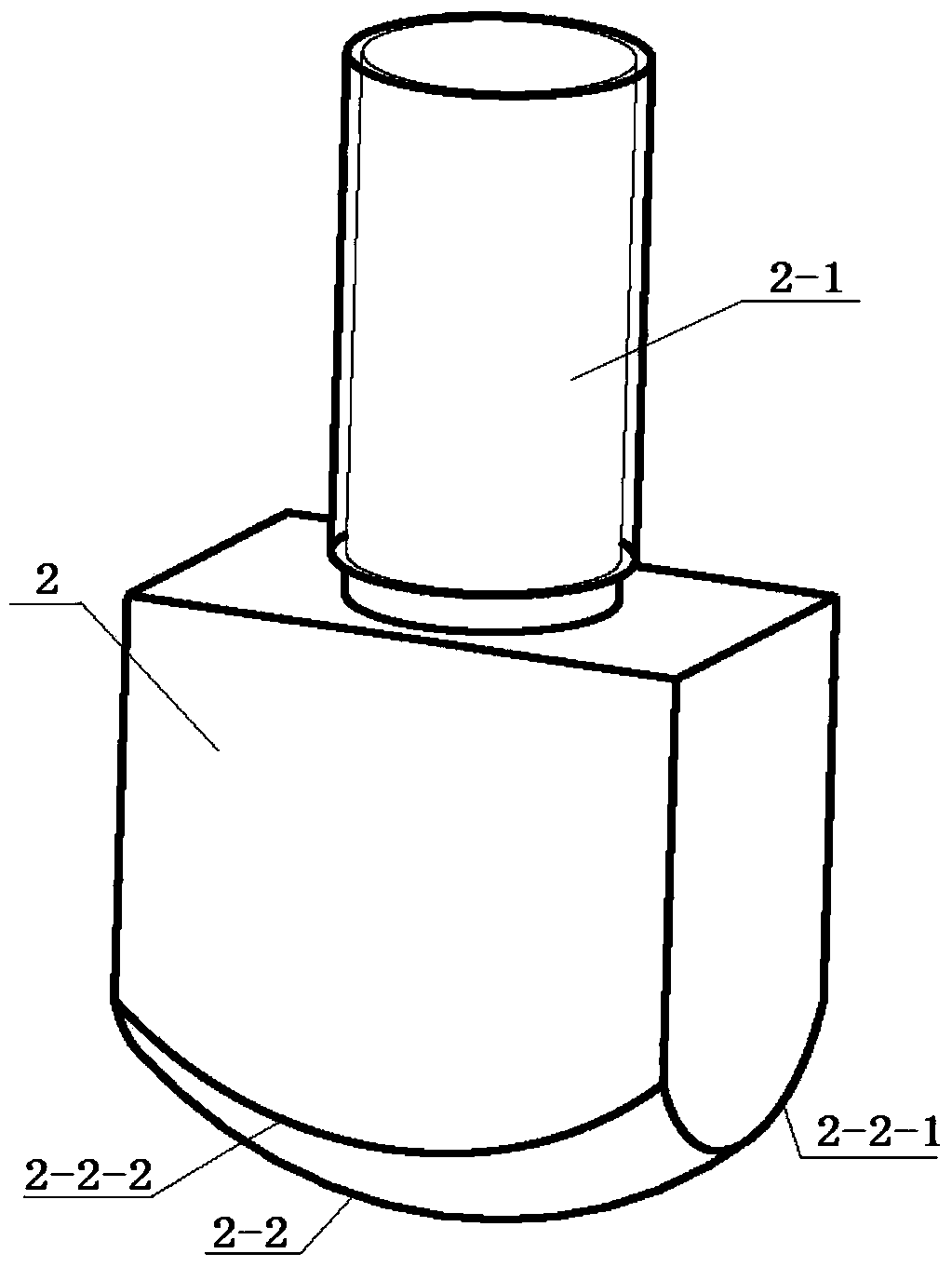

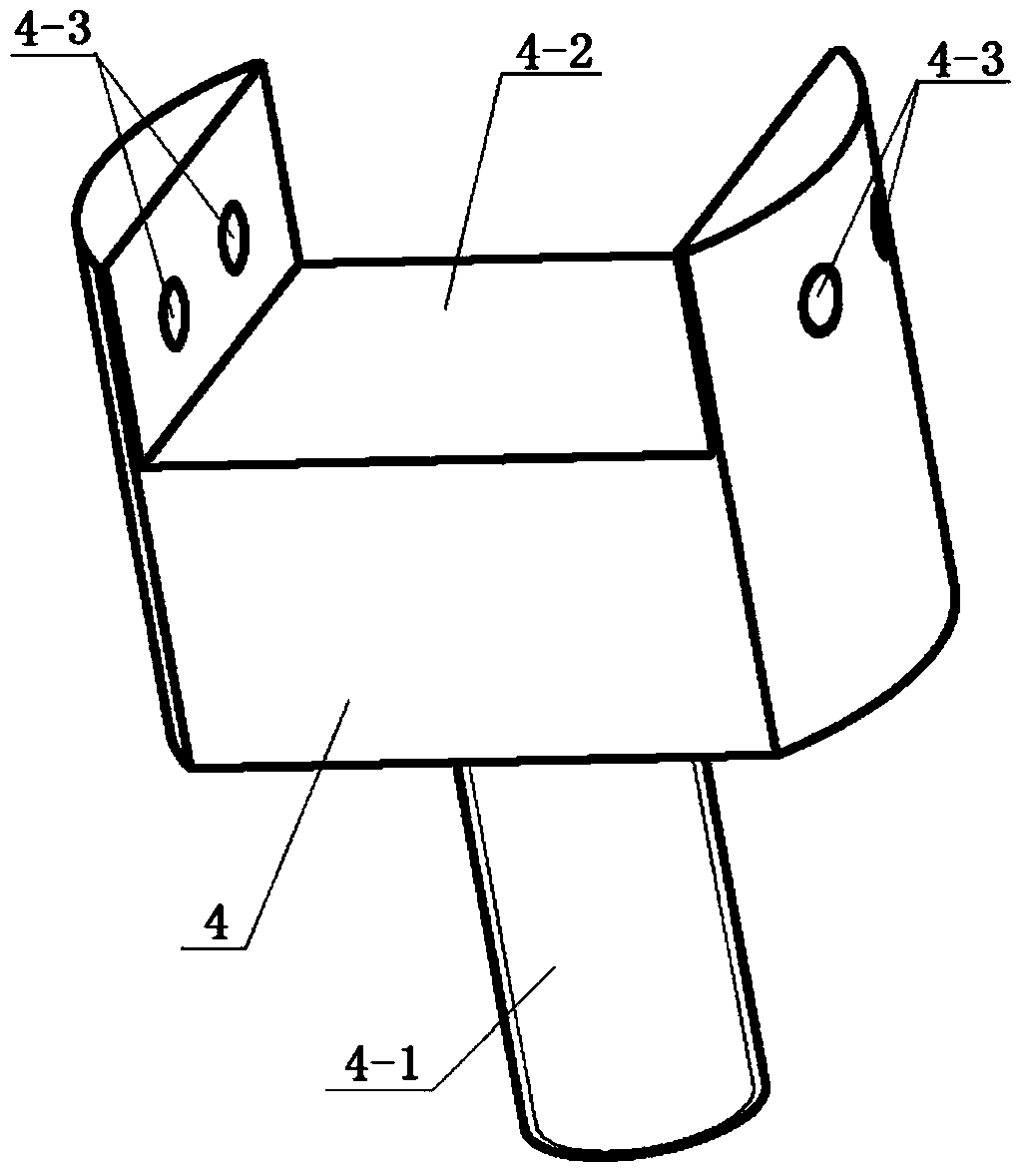

[0012] Specific implementation mode one: combine Figure 1 to Figure 5 Describe this embodiment, this embodiment comprises upper nut 1, punch 2, die 3, die base 4, lower nut 6, ejector rod 7 and four positioning bolts 5, the lower end of die base 4 is provided with lower The connecting bolt 4-1, the upper end of the die base 4 is provided with a die through groove 4-2, and each side wall of the die base 4 corresponding to the die through groove 4-2 is provided with two positioning screw holes 4-3 , the two positioning screw holes 4-3 on the left side wall are in one-to-one correspondence with the two positioning screw holes 4-3 on the right side wall, each positioning screw hole 4-3 is threaded to connect a positioning bolt 5, and the die 3 is set In the die through groove 4-2, the upper end surface of the die 3 is provided with a double-curvature arc groove 3-1, and the double-curvature arc groove 3-1 is provided with a transverse arc groove 3-1- 1. The double-curvature arc ...

specific Embodiment approach 2

[0014] Specific implementation mode two: combination figure 2 and Figure 4 To describe this embodiment, the difference between the radius of curvature of the transverse arc groove 3-1-1 and the radius of curvature of the transverse arc surface 2-2-1 in this embodiment is the thickness of the forming sheet. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0015] Specific implementation mode three: combination figure 2 and Figure 4 To describe this embodiment, the difference between the radius of curvature of the longitudinal arc groove 3-1-2 and the radius of curvature of the longitudinal arc surface 2-2-2 in this embodiment is the thickness of the forming sheet. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com