A carbon dioxide capture solution enhanced regeneration system and method

A carbon dioxide and regeneration system technology, applied in chemical instruments and methods, separation methods, inorganic chemistry, etc., can solve problems such as increasing technology application costs, and achieve the effects of reducing degradation loss, consumption, and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

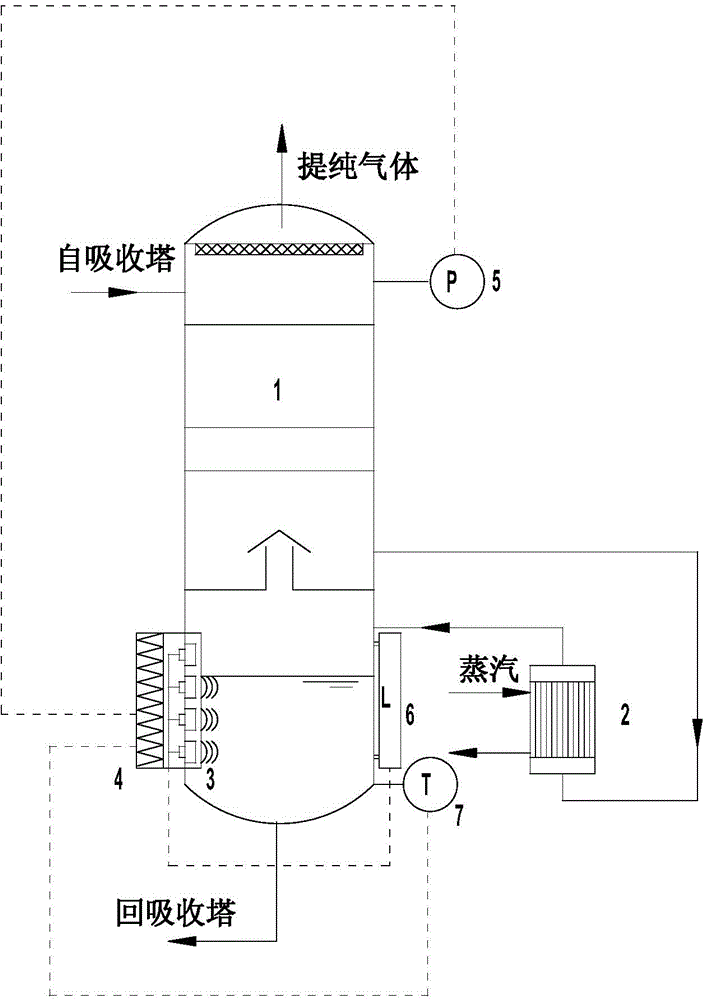

[0025] as attached figure 1 , the regeneration tower 1 is connected with the absorption tower, and the absorption solution reacts with carbon dioxide in the absorption tower to form a rich liquid and leaves the absorption tower, enters the regeneration tower 1 from the top of the regeneration tower 1 and flows to the bottom, and the solution enters the vertical tower connected to the lower part of the regeneration tower 1 side Type or horizontal thermosyphon reboiler 2, reboiler 2 provides heat source from external steam, absorbs solution and returns to regeneration tower 1 after absorbing heat, and maintains temperature and pressure in regeneration tower 1.

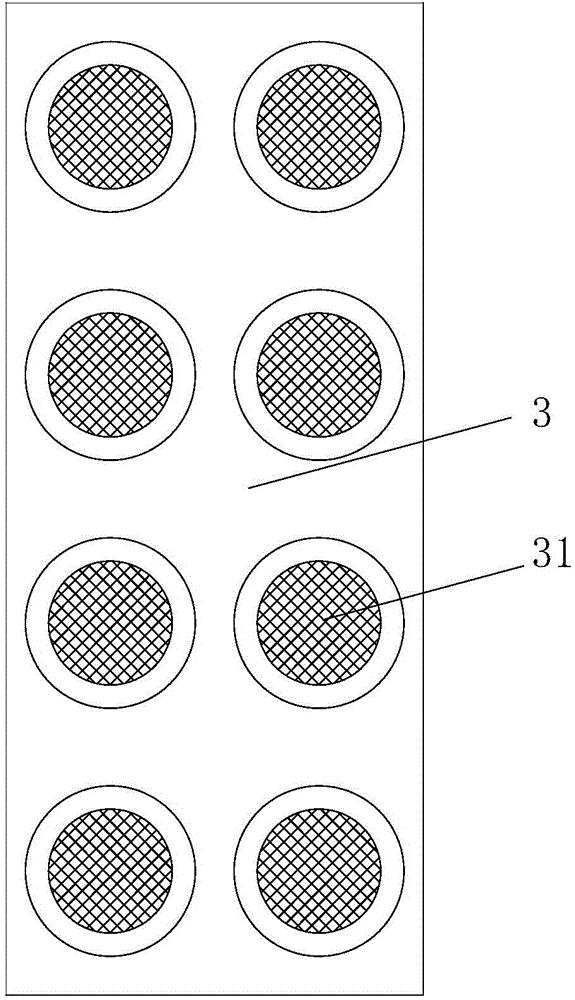

[0026] Two sonotrode panels 3 are parallel and equal in height and stand on both sides of the bottom side wall of the regeneration tower 1, such as figure 2 As shown, the ultrasonic generator panel 3 is composed of multiple sets of ultrasonic vibrators located at different heights. The vibrators output continuous or pul...

Embodiment 2

[0028] The structure of regeneration tower 1 and reboiler 2 is consistent with that of example 1. Ultrasonic generator panel 3 is placed flatly at the bottom of regeneration tower 1, and ultrasonic waves are output from the bottom to the solution, and the solution flowing into regeneration tower 1 from reboiler 2 is completely immersed in ultrasonic generator The ultrasonic generator panel 3, according to the liquid level information at the bottom of the regeneration tower fed back by the liquid level sensor 6, after the liquid level reaches a certain value, the vibrator of the ultrasonic generator panel 3 starts to work, and the number of working vibrators is adjusted according to the change of the liquid level. The ultrasonic controller 4 modulates the output frequency and power of the vibrator on the ultrasonic generator panel 3 according to the feedback values of the pressure sensor 5 and the temperature sensor 7. When the modulation frequency and power range are lower tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com