Method of manufacturing printed circuit board

A technology of printed circuit substrates and base substrates, which is applied in the direction of assembling printed circuits, circuits, and electrical components with electrical components. It can solve the problems of solder ball falling off and difficult to control the position with high precision, and achieve the effect of preventing falling off and preventing aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

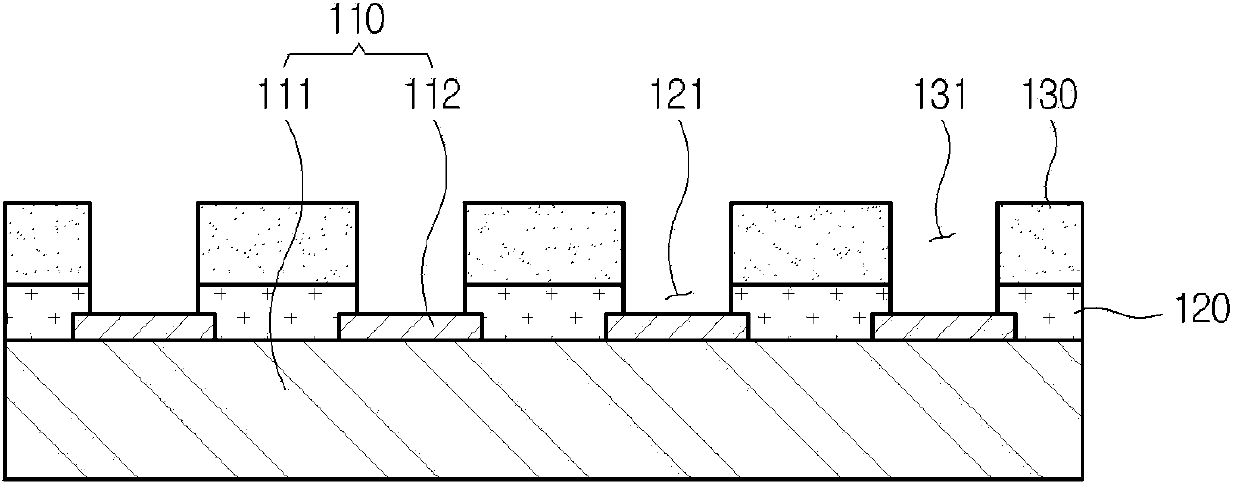

[0035] The purpose, specific advantages, and novel features of the present invention will be further clarified by the following detailed description and preferred embodiments with reference to the accompanying drawings. In this specification, when assigning reference numerals to constituent elements in each drawing, care must be taken to attach the same numerals as much as possible even if the same constituent elements are shown in different drawings. In addition, terms such as "one side", "the other side", "first", and "second" are used to distinguish one component from other components, and the components are not limited by the terms. Hereinafter, when describing the present invention, detailed descriptions related to well-known technologies that may obscure the gist of the present invention will be omitted.

[0036] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

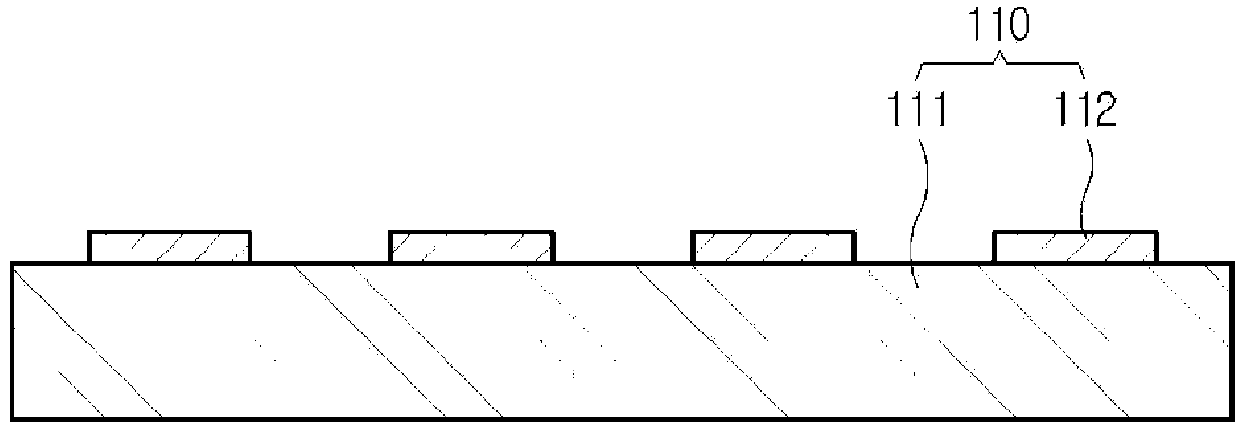

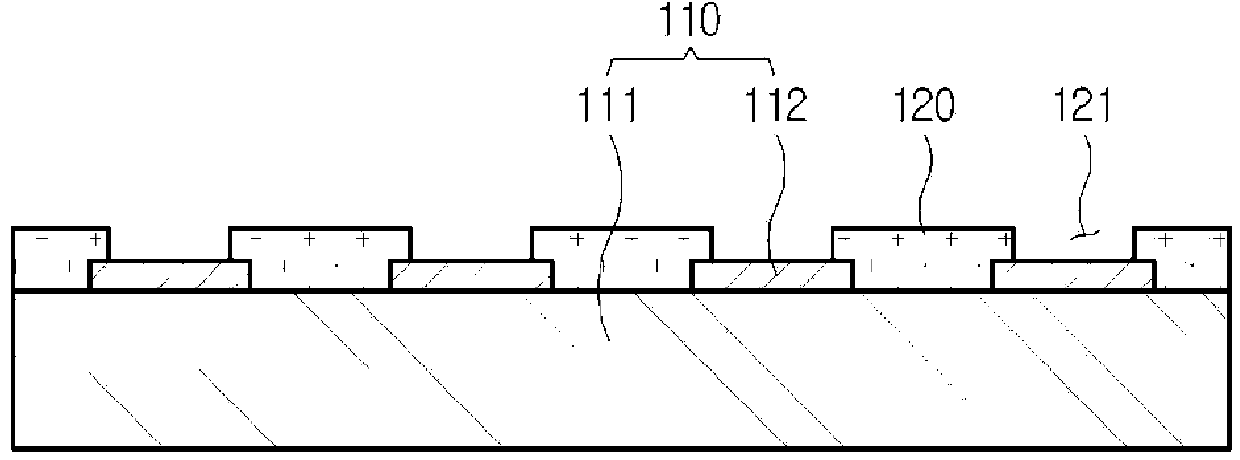

[0037] Manufacturing met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com