An end-face contact charging and discharging connector

A connector, charge and discharge technology, applied in the direction of connection, contact parts, two-part connection device, etc., can solve the problems of not having the function of displacement and angle compensation, increasing contact resistance, damaging the coating of contact parts, etc., to reduce the risk of arcing risk, improved contact reliability, and improved mechanical life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

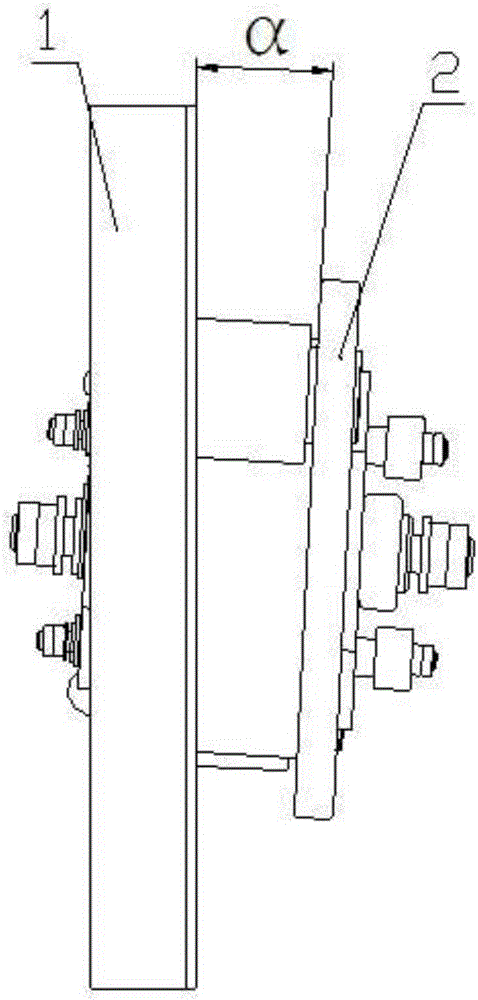

[0025] like figure 1 As shown, an end-face contact charging and discharging connector includes a socket 1 and a plug 2 .

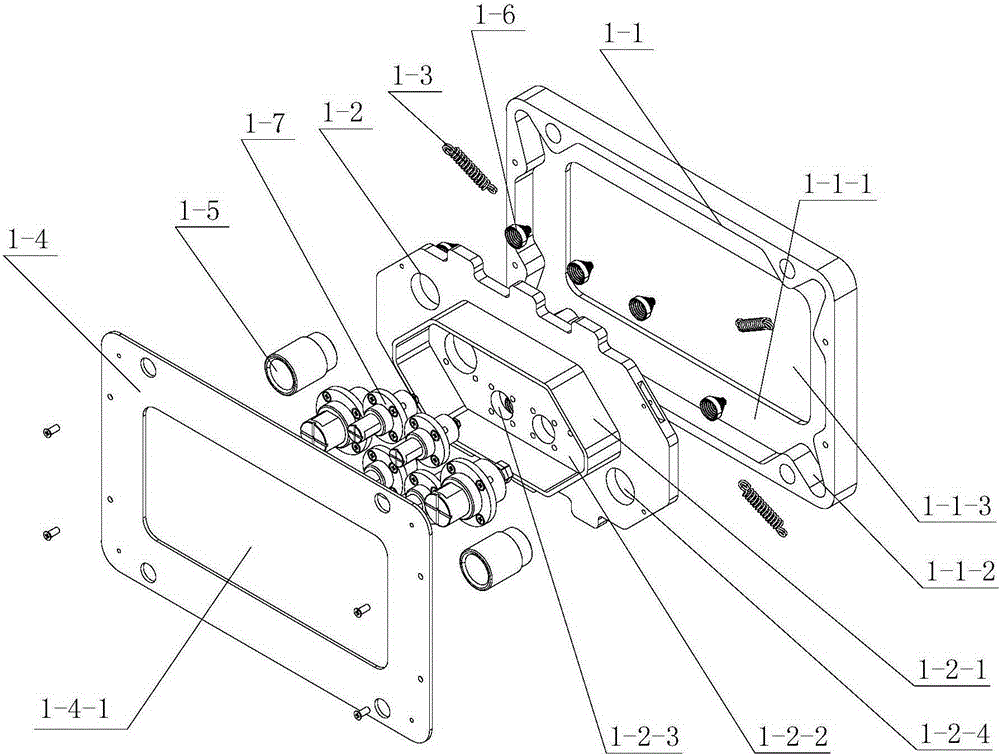

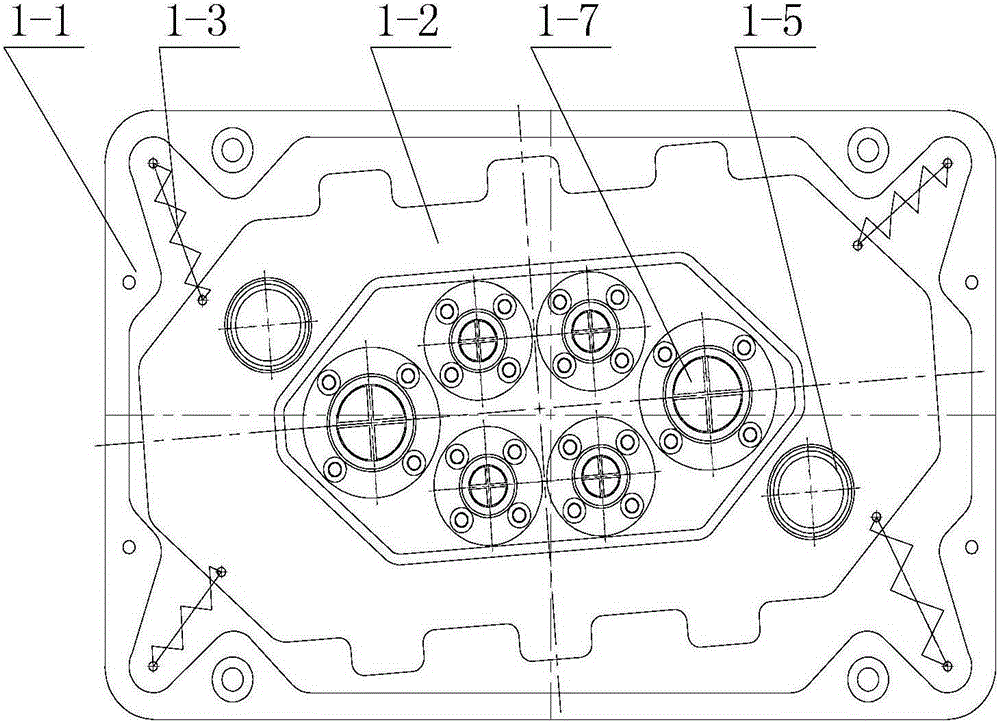

[0026] like figure 2 , 3 As shown in and 4, the socket 1 includes a base 1-1, a floating plate 1-2, an elastic body 1-3, a cover plate 1-4, a guide sleeve 1-5, a tower spring 1-6 and a moving contact assembly 1-7 ; One end of the base 1-1 is provided with a floating plate installation cavity 1-1-1, and the edge of the floating plate installation cavity 1-1-1 is provided with four elastic body installation cavities 1-1-2, each elastic body installation cavity 1-1-2 are all connected with the floating plate installation cavity 1-1-1; the bottom of the floating plate installation cavity 1-1-1 is provided with a moving contact assembly protruding hole 1-1-3, and the moving contact assembly extends The bottom of the outlet hole 1-1-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com