Fuel cell stack assembly method

A fuel cell stack and assembly method technology, which is applied to fuel cell grouping, fuel cells, fuel cell additives, etc., can solve the problems of difficulty in guaranteeing the life of the stack, increasing costs, and lack of improvement means, and achieves the benefits of uniform distribution, The effect of ensuring the quality of the stack and improving the assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

[0024] The embodiment is to assemble a stack of 100 single cells.

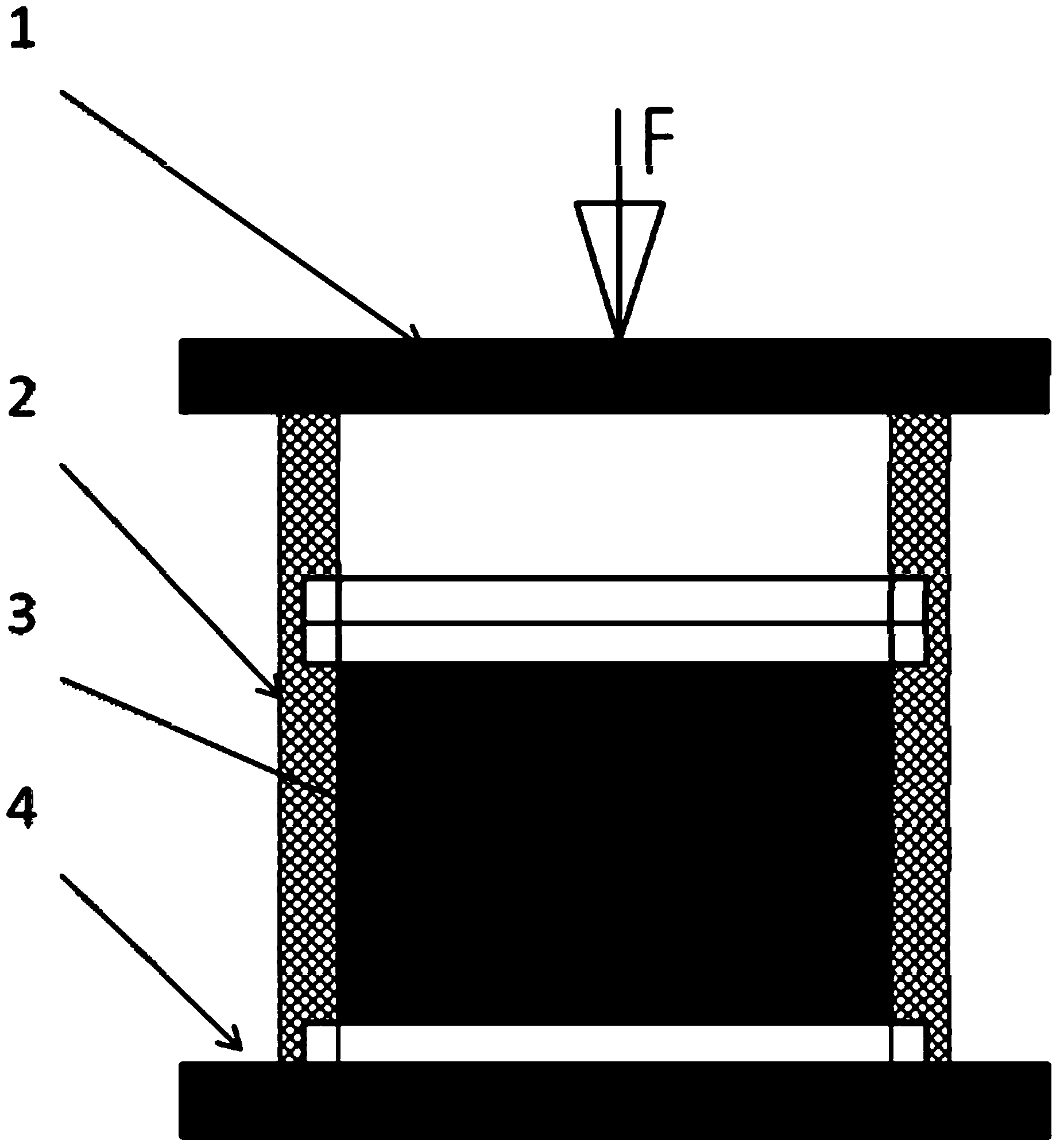

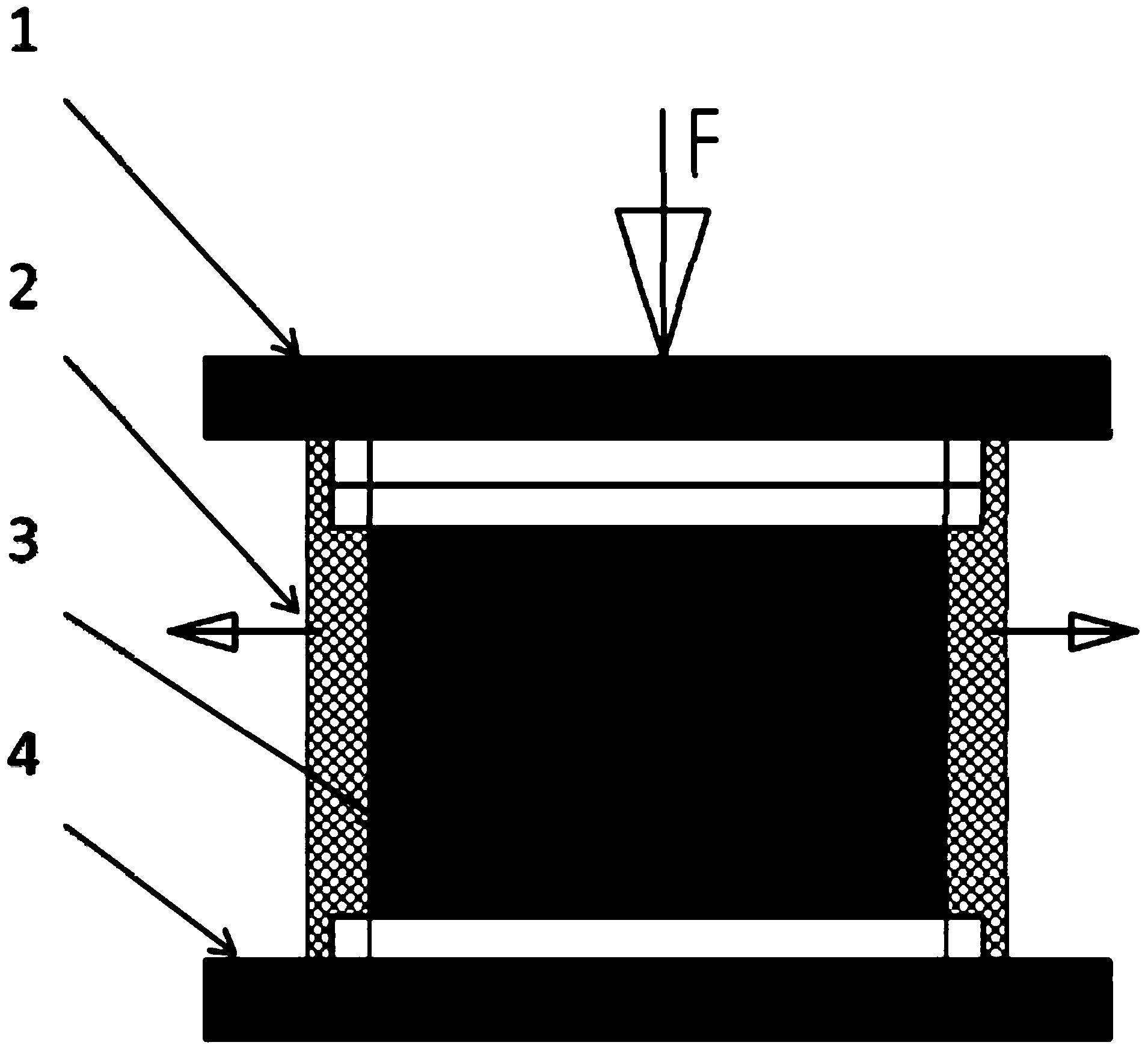

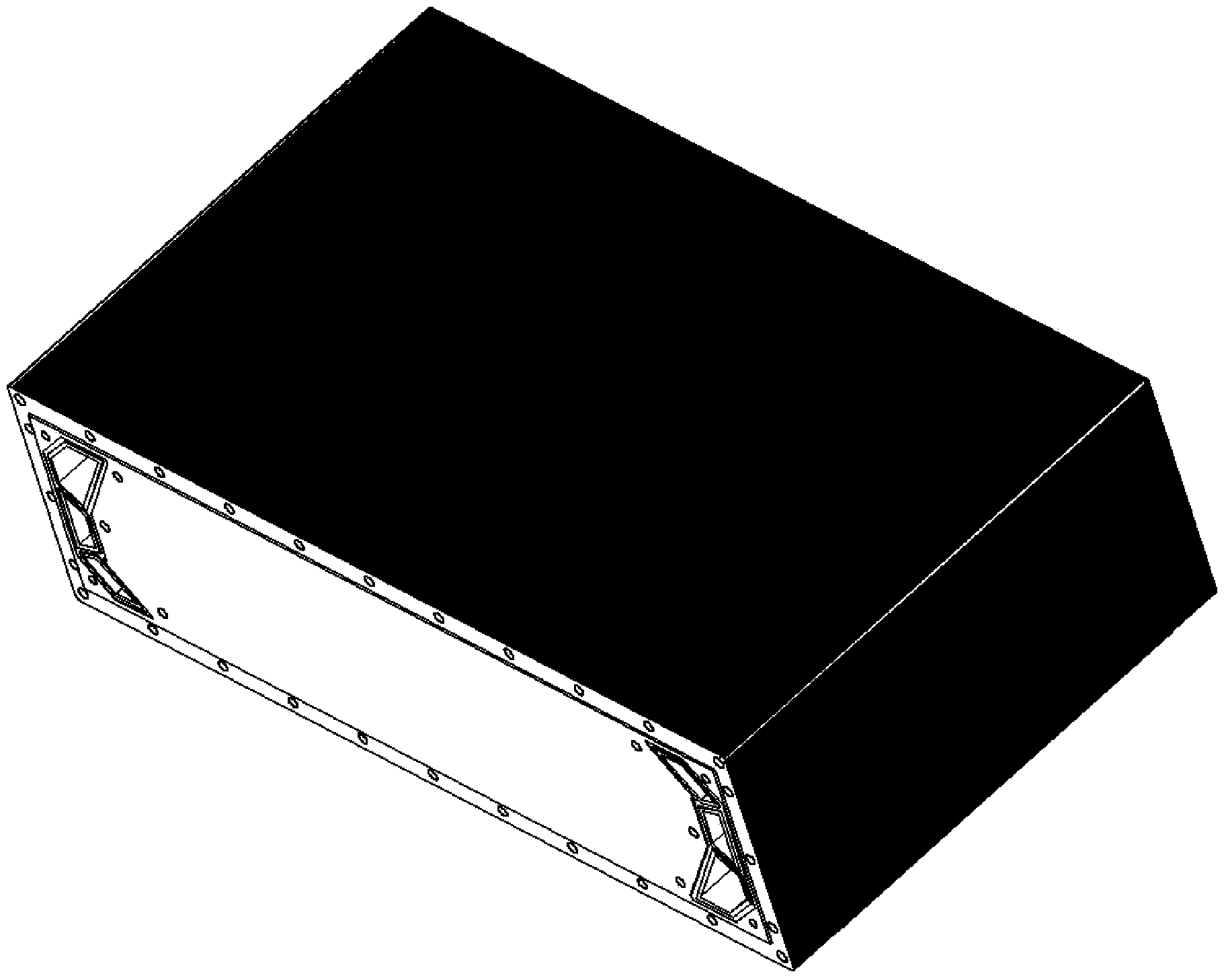

[0025] First, fix the outer positioning tool 2 on the fixed lower plate of the DWD150 universal testing machine; put the lower end plate, lower current collector plate, 100-cell single cell, upper current collector plate, upper end plate, etc. into the outer positioning in order Stack neatly inside the tooling 2; apply an assembly force to the stack to the set value of 50kN through a universal testing machine; remove the outer positioning tooling 2, and fasten the side plates of the 2mm thick 304SS integrated package to the end plates of the stack with screws; slowly Remove the additional stack assembly force of the universal testing machine until the displayed pressure is 0, take out the fuel cell stack 3, and the assembly is complete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com