Lead-acid battery curved panel grid

A technology of lead-acid batteries and grids, which is applied in the direction of electrode carriers/collectors, etc., can solve the problems of low bonding strength between active materials and grids, no increase in battery specific energy, and impact on battery life, so as to achieve easy molding and improved Effects of specific energy and life extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

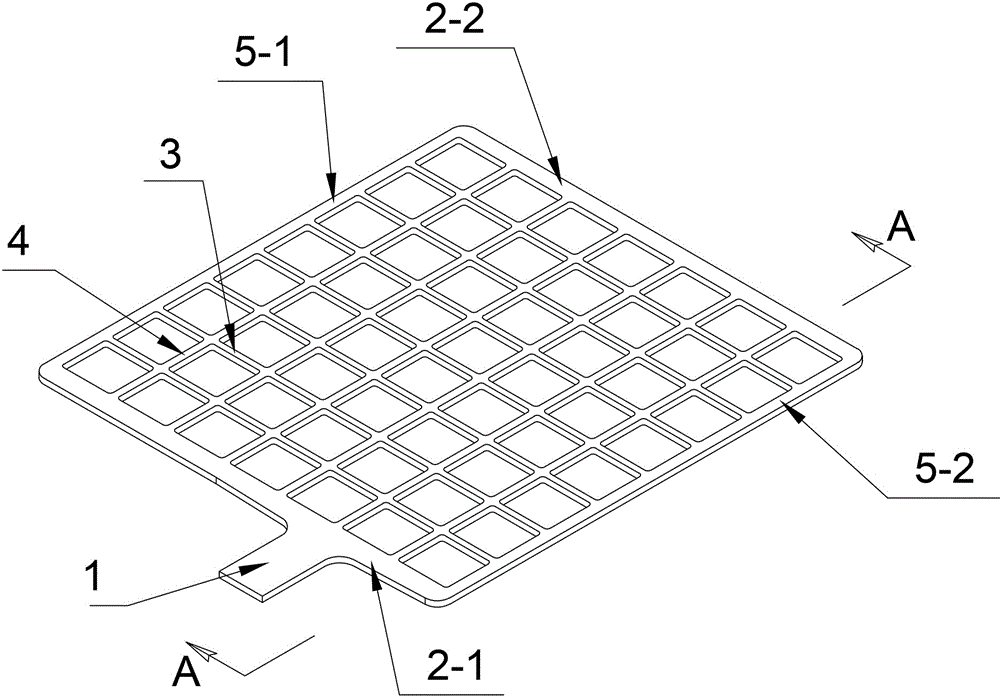

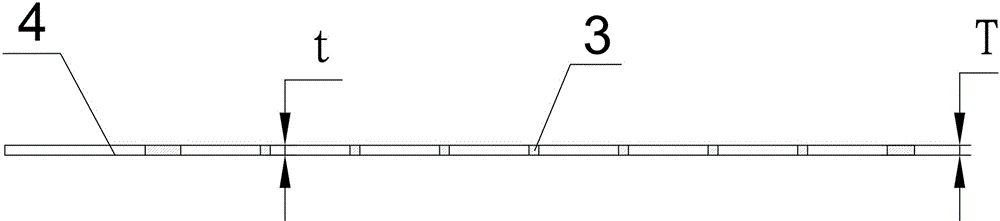

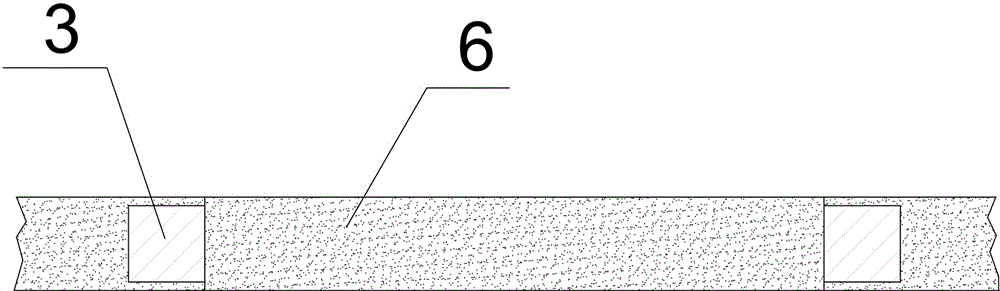

[0032] like Figure 4 and Figure 5 In the illustrated embodiment 1, this embodiment includes a frame, a plurality of ribs and tabs 1 with an integral structure. The frames include horizontal frames 2-11 and 2-21 and vertical frames 5-11 and 5-21, and the ribs include longitudinal ribs 4-1 and transverse ribs 3-1. The longitudinal ribs 4-1 and the transverse ribs 3-1 are interwoven into a rib network, the grid shape is rectangular, and the grid shape can also be rhombus or other shapes. The longitudinal frames 5-11 and 5-21 and the longitudinal ribs 4-1 are continuous arc-shaped curves with obvious crests and troughs, the crests and troughs have the same shape and size, and the arrangement is reversed. The spacing between them is equal, each vertical frame 5-11 and 5-21 and each longitudinal rib 4-1 are on the same position parallel to the horizontal frame 2-21 (that is, parallel lines for the horizontal frame 2-21, each vertical The crests 9 or troughs 10 distributed by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com