Aircraft buffer variable damping oil needle

A buffer and variable damping technology, applied in shock absorbers, shock absorbers, mechanical equipment, etc., can solve the problems of energy absorption affecting buffers, monotonous variable damping parameter curves, low buffer efficiency, etc., and achieve efficiency coefficients. Improvement, significant technical effect, full power curve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

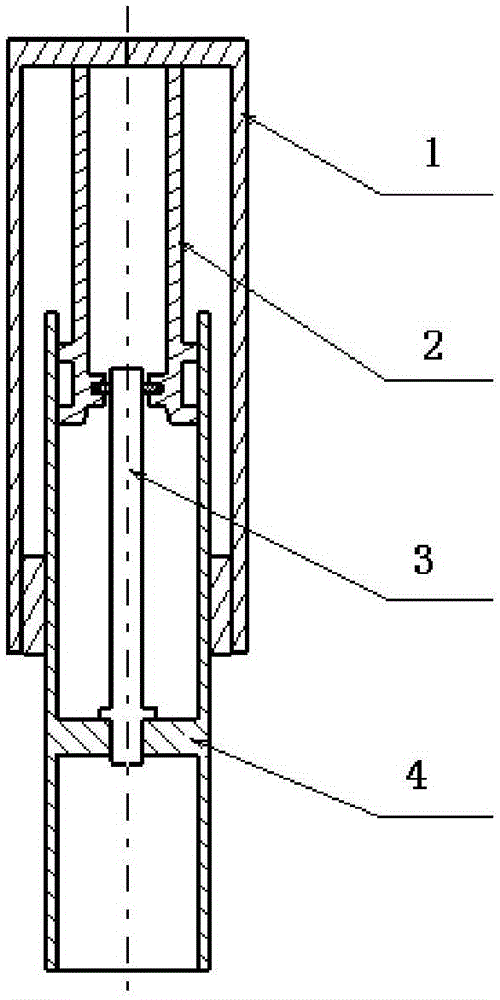

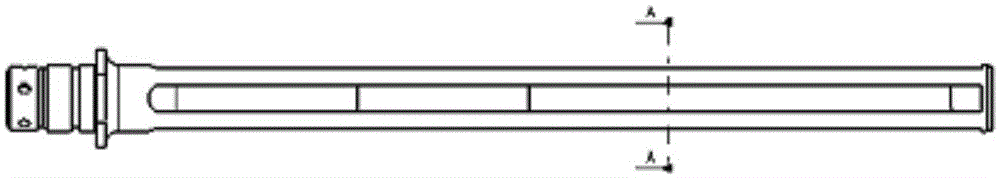

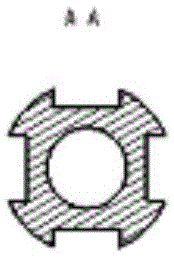

[0017] see figure 1 , which is a schematic diagram of the installation structure of the variable damping oil needle of the aircraft buffer of the present invention. The variable damping oil needle of the aircraft buffer of the present invention, its lower end is installed inside the piston rod 4, and its upper end is inserted into the plunger 2 to form a buffer damping device together. When the buffer is compressed, the piston rod 4 and the oil needle 3 are quickly inserted into the outer Inside the barrel 1, the oil in the piston rod quickly flows through the groove on the surface of the needle body of the oil needle to generate a damping force. The variable damping oil needle of the aircraft buffer of the present invention is a cylindrical needle body. see figure 2 , the outer surface of the needle is provided with several longitudinally distributed gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com