Vaporizer type engine with oil saving device

A technology for engines and carburetors, which is applied in the direction of machines/engines, engine components, charging systems, etc., can solve the problems of poor atomization of carburetors, low utilization rate of gasoline, insufficient combustion, etc., to achieve good economy and Effects of social benefit, improvement of mixing ratio, and improvement of utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

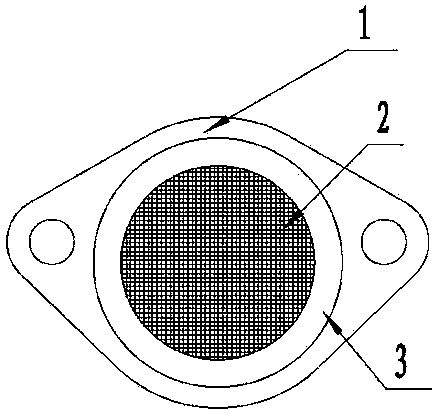

[0011] Such as figure 1 Shown, the present invention comprises carburetor type engine body, and it also has fuel-saving device, and fuel-saving device is made up of fixed plate 1, atomizing net 2 and seal ring 3, and fixed plate 1 is installed on the carburetor and the carburetor of carburetor type engine body Between the engine interface, there is a hole on the fixed plate 1, the hole on the fixed plate 1 is located at the interface between the carburetor and the engine, the atomizing net 2 is installed in the hole of the fixed plate 1, and the periphery of the atomizing net is in contact with the fixed plate A sealing ring is provided between them. The atomizing net 2 is made of corrosion-resistant plastic or metal.

[0012] The fixed plate 1, the atomizing net 2 and the sealing ring 3 are integrated.

[0013] working principle:

[0014] 2. The fuel-saving device is installed between the carburetor and the engine interface. When the engine is running, the mixed airflow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com