Technological cylinder gasket for machining of cylinder holes of cylinder body of engine

A technology for engine cylinders and cylinder head gaskets, which is applied to engine sealing devices, engine components, machines/engines, etc., and can solve problems such as affecting engine performance and life, increasing wear of piston rings and cylinder bores, and poor cylinder bore roundness. , to achieve the effect of improving performance and life, reducing oil consumption, and not easy to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to further explain the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings.

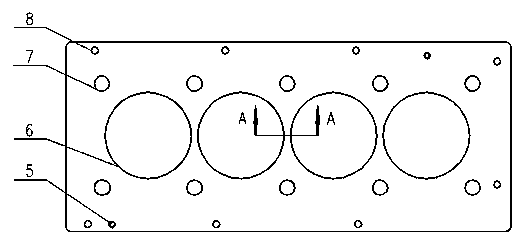

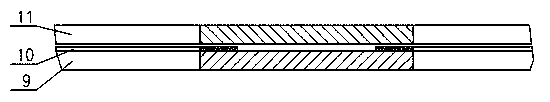

[0013] Such as figure 1 and figure 2 As shown, the process cylinder gasket 2 for processing the cylinder bore of the engine cylinder block includes an upper cylinder gasket plane layer 11 and a lower cylinder gasket plane layer 9 stacked up and down, and the upper and lower cylinder gasket plane layers 11, 9 are passed through the rivets 5 Fixed as a whole, four cylinder holes 6, eight installation holes 8 and ten bolt through holes 7 are opened on the process cylinder head gasket 2, and thickening parts 10 are arranged between the upper and lower cylinder head gasket plane layers 11 and 9 , the thickened part 10 is located around the cylinder bore 6, the thickened layer 10 can be a part of the lower cylinder head gasket plane layer 9, formed by flanging around the cylinder hole on the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com