Multifunctional foamed concrete composite self-heat-preservation block and forming method thereof

A technology of foamed concrete and self-insulating blocks, which can be applied to building materials, etc., can solve the problems that heat insulation cannot be completed in one step, the product is light but not high-strength, high-strength and heavy-weight, etc. The method is simple and ingenious, reducing masonry Cost, full-featured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

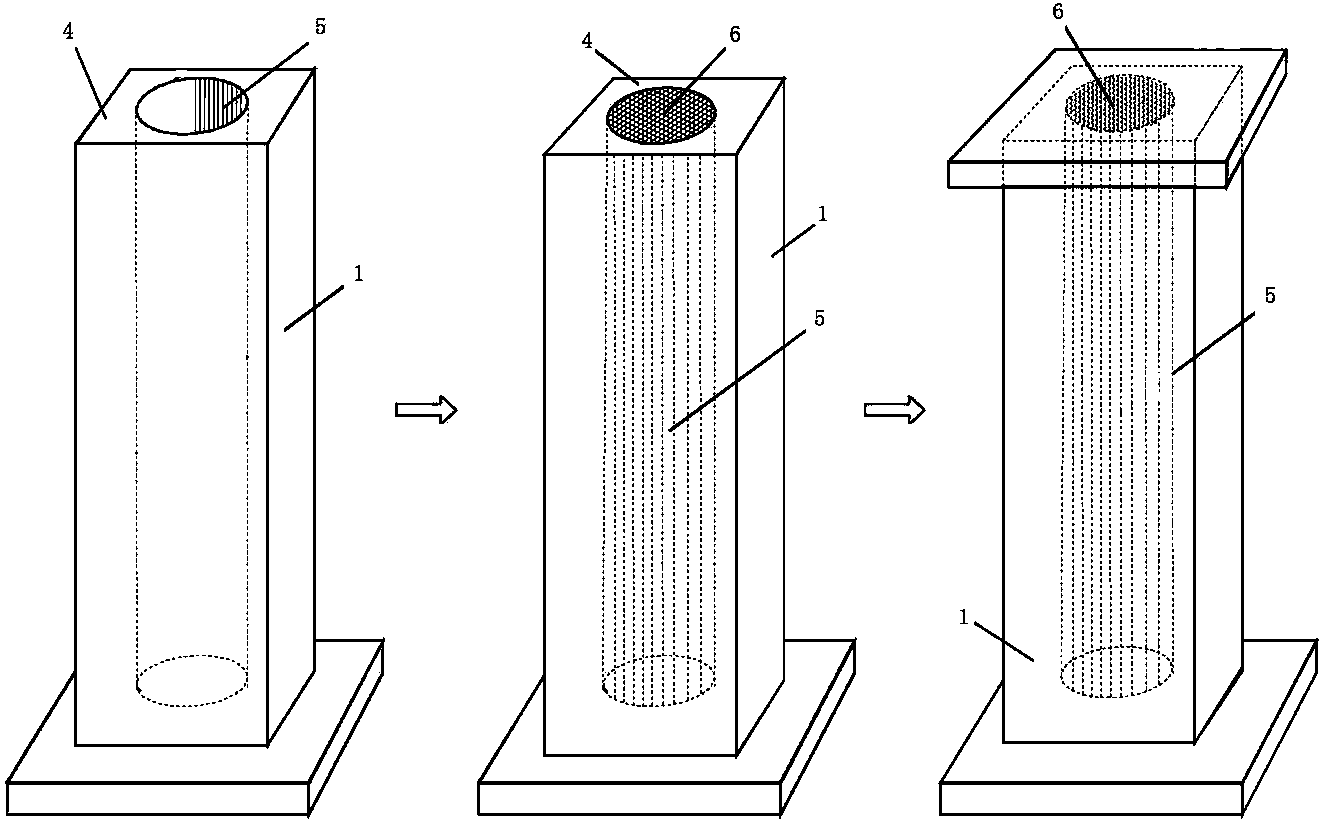

[0039] Depend on Figures 1 to 26 It can be seen that the present invention is a foam block composed of upper, lower, front and rear four side walls 1 and left and right two end faces 4, wherein:

[0040] The center of the block is provided with a middle cavity 5 filled or poured with a foaming material 6, and the middle cavity 5 is a through hole with an opening on the two end faces 4, or a blind hole with an opening on one end face 4, or an opening on one side. Blind holes in side wall 1;

[0041] The foam material 6 fills the middle cavity 5 to form a double foam block, or the foam material 6 fills the middle cavity 5 and shrinks naturally to form a double foam block with a hollow chamber 5'.

[0042] The hollow rate of the block described in the present invention is that the middle cavity 5≤30%, and the cross section of the middle cavity 5 is a circular or square or octagonal through hole or blind hole, such as figure 1 , 9 , 10, 23, 24. The middle cavity 5 is a blind ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com