Method and device for automatically arranging, stacking and plastically packaging coin rolls

An automatic arrangement and automatic stacking technology, applied in packaging, wrapping paper, transportation packaging, etc., can solve the problems of unable to meet the production needs of coin packaging, reduce labor intensity, and low production efficiency, and achieve simple structure, convenient operation, and high production efficiency. high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (Example 1, a device for automatically arranging and stacking coin rolls for plastic packaging)

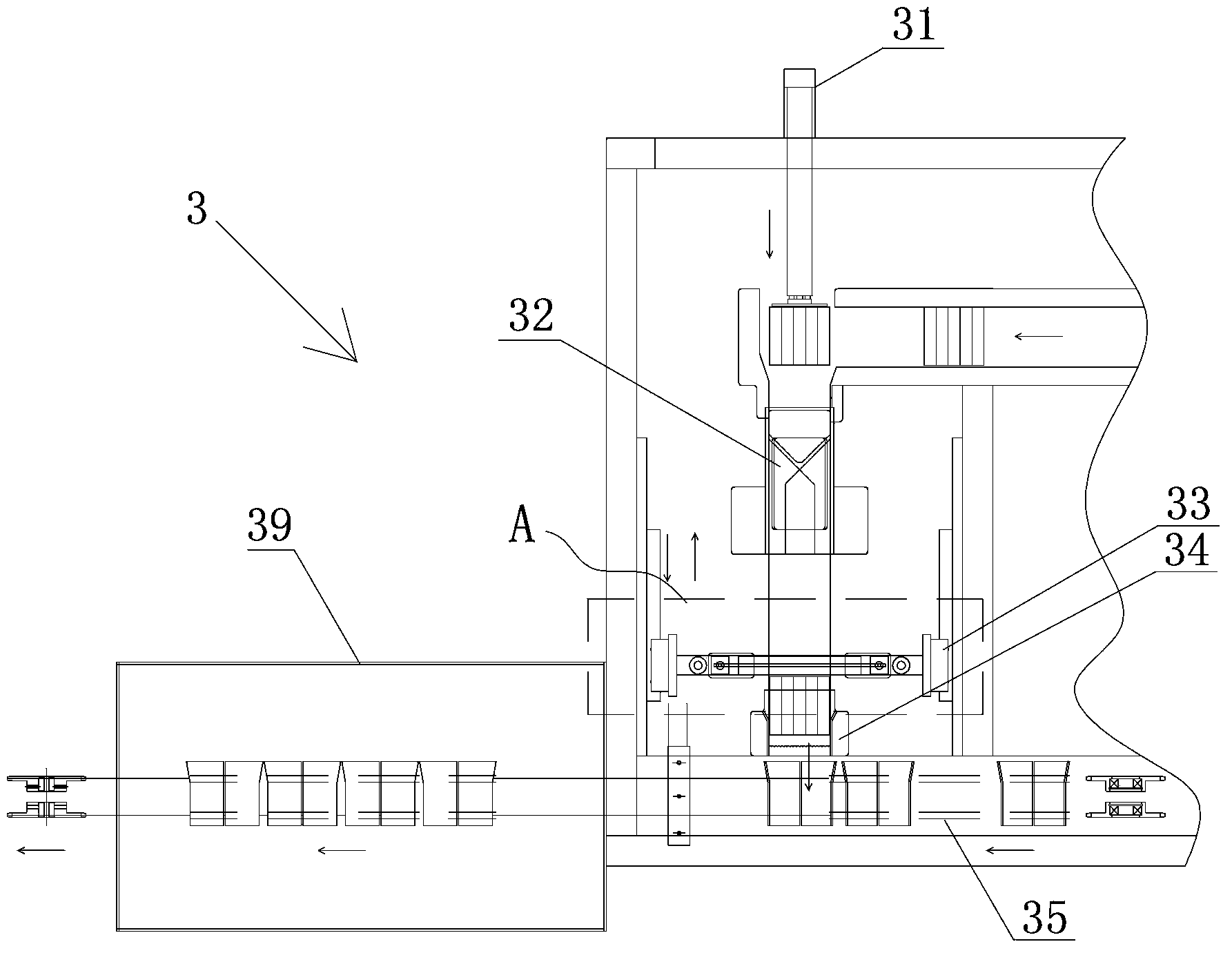

[0030] See Figure 1 to Figure 5 , a device for automatically arranging and stacking plastic packaging of coin rolls, comprising an automatic arranging device 1, an automatic stacking forming device 2 and an automatic plastic packaging device 3 arranged in sequence;

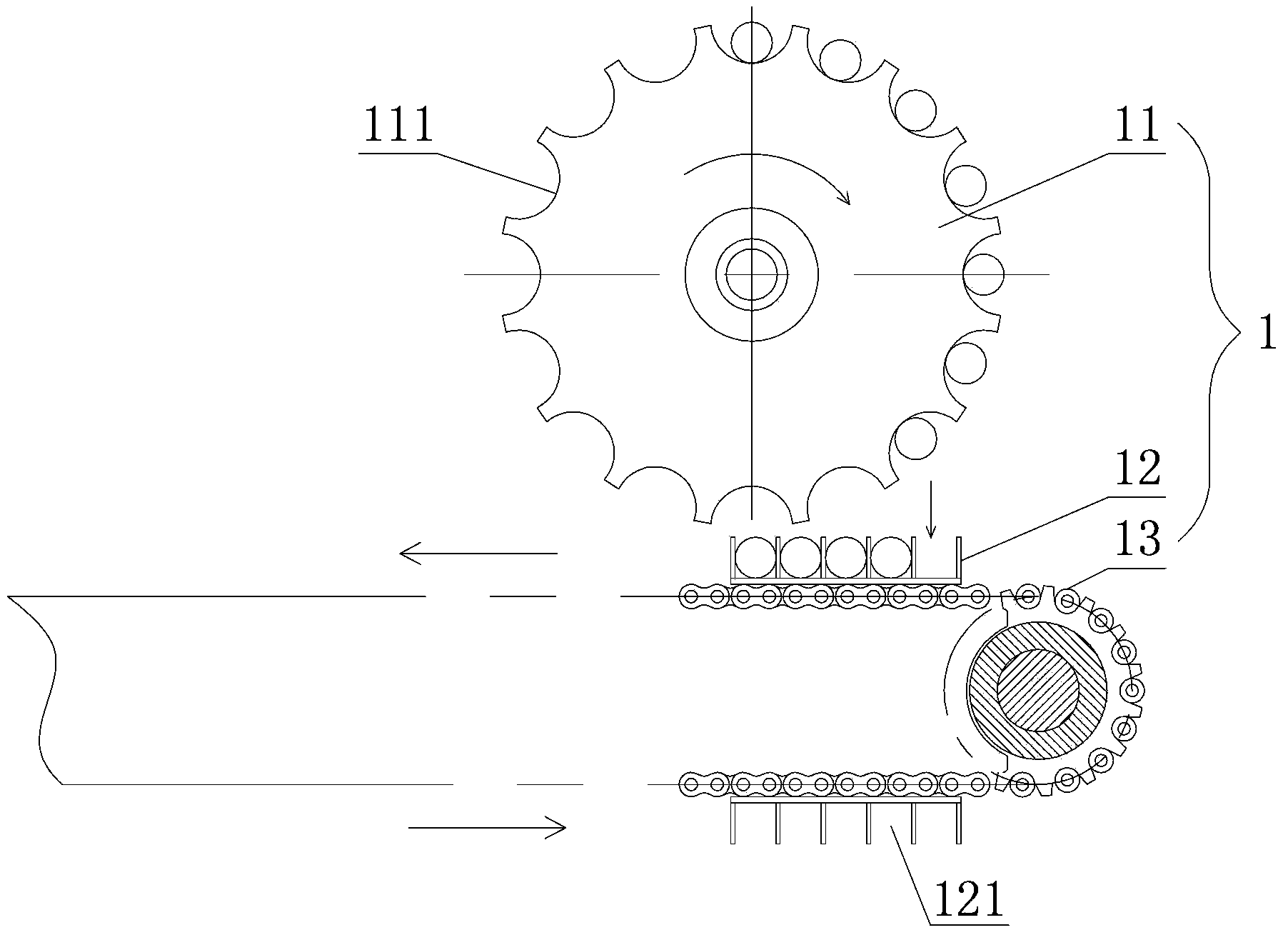

[0031] The automatic arranging device 1 has a coil receiving carousel 11, a coil receiving container 12 and a conveying device 13; the coil receiving carousel 11 is in the shape of a ratchet, and the coil receiving carousel 11 is rotatably arranged above the coil receiving container 12; the coil receiving container 12 is fixedly arranged on the conveying device 13, the transmission device 13 is driven by a sprocket, and there is a storage tank 121 in the coil receiving container 12; the storage tank 121 is set corresponding to the ratchet groove 111 of the coil receiving carousel 11;

[0032] The automatic st...

Embodiment 2

[0034] (Embodiment 2, the method for automatically arranging and stacking plastic packaging of coin rolls)

[0035] A method for automatically arranging and stacking plastic packaging of coin rolls has the following steps:

[0036] a. Regular arrangement of coin rolls: the coin rolls enter the ratchet-shaped take-up turntable 11 that moves in a step-rotation manner through the assembly line, and are placed one by one at the ratchet grooves 111 of the take-up turntable 11. Rotate, the coin rolls fall into the storage slot 121 of the roll receiving container 12 in sequence and automatically arrange regularly, and move to the automatic stacking forming device 2 through the conveying device 13;

[0037] b. Coin roll stacking and forming: push the arranged coin rolls into the first stacking container 22 and the second stacking container 23 row by row through the push roll cylinder 21, and stack them layer by layer into a cuboid stack; The stacked coin rolls are moved to the automa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com