Tunnel type car washer

A car washing machine and tunnel-type technology, applied in the direction of vehicle exterior cleaning devices, etc., can solve the problems of poor cleaning effect, insufficient cleaning, waste of water resources, etc., achieve good cleaning effect, good air-drying effect, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific technical solutions of the present invention will be further described below with reference to the accompanying drawings, so that those skilled in the art can further understand the present invention, without limiting their rights.

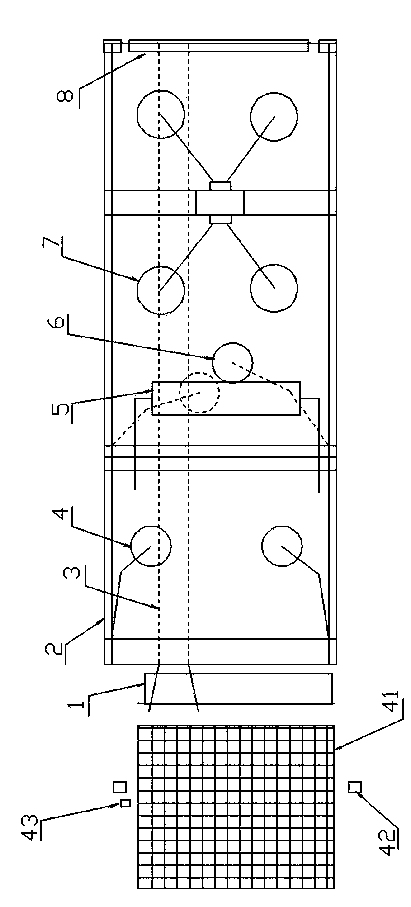

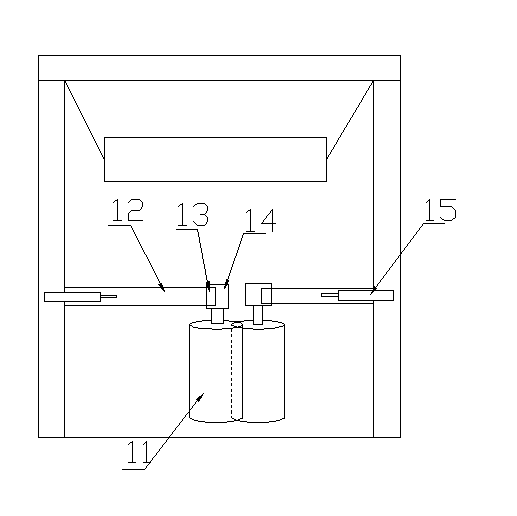

[0020] refer to figure 1 , a tunnel type car washing machine, comprising a tunnel frame 2, the tunnel frame 2 is provided with a wheel guide rail 3 arranged parallel to the axis of the tunnel, and a vehicle adjustment and guiding device 1 is provided at the vehicle inlet end of the wheel guide rail 3, from which the vehicle The left and right wheel brushes 4, the horizontal brushes 5, the left and right license plate vertical brushes 6, the vertical brushes 7 swinging on both sides and the lifting blowing device 8 are arranged successively between the left and right racks of the tunnel from the entrance end to the vehicle exit end.

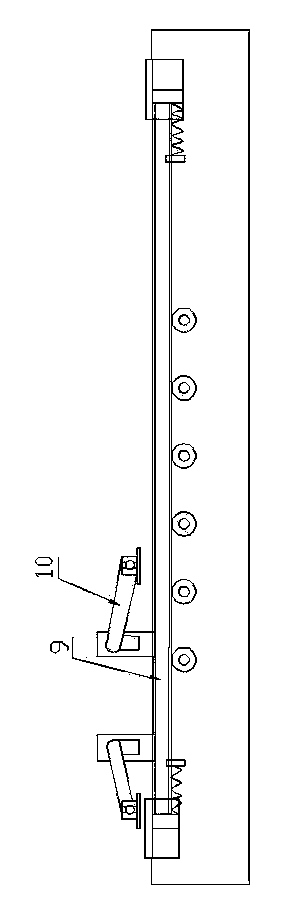

[0021] The vehicle adjustment and guiding device includes a laterally movable slide plate 9 arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com