Front anti-collision beam assembly assembling tool for vehicle

A technology for assembly of front anti-collision beams and assemblies, which is applied in the direction of manufacturing tools and workpiece clamping devices, can solve the problems of difficulty in assembly in OEMs, low production efficiency, difficulty in ensuring the flatness of assembly surfaces and the accuracy of assembly holes, etc. Achieve the effect of improving assembly efficiency and improving assembly dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

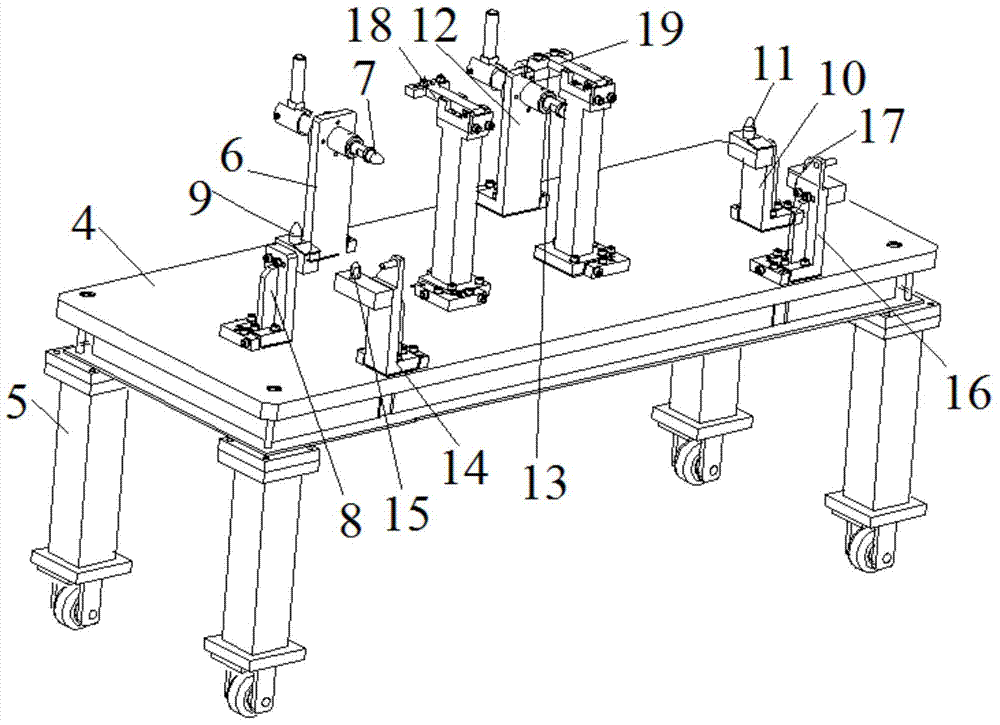

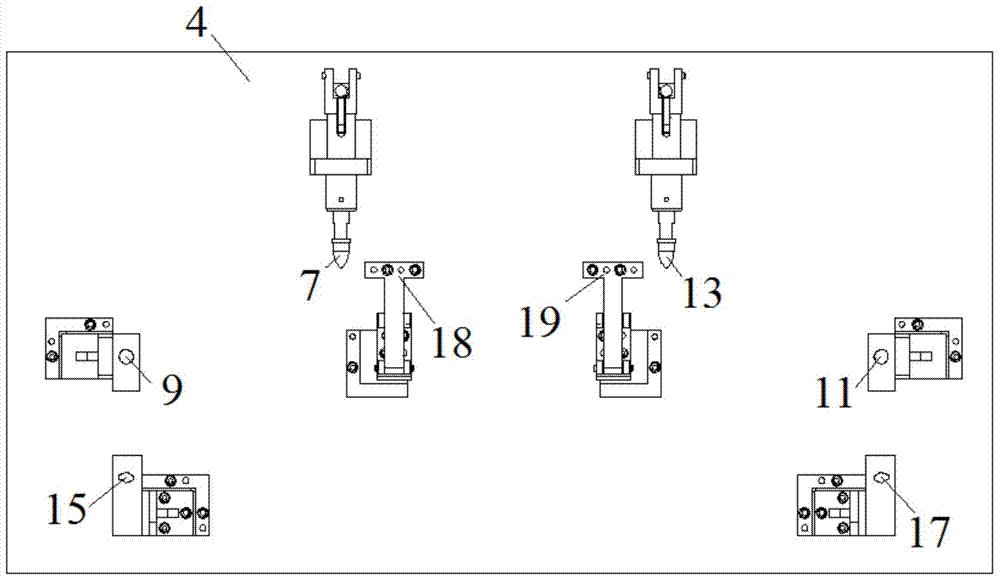

[0016] Such as figure 2 and image 3 Shown, the present invention a kind of automobile front anti-collision beam assembly assembly tooling, is used for the assembling of front anti-collision beam assembly, and front anti-collision beam assembly is as follows figure 1 As shown, it includes an anti-collision beam body 1 and two mounting brackets, the left mounting bracket 2 on the left side of the anti-collision beam body 1, and the right mounting bracket 3 on the right side of the anti-collision beam body 1 . The assembly tooling includes a base, which is provided with a body positioning device for positioning the anti-collision beam body 1 and two bracket positioning devices for positioning the two mounting brackets. The two bracket positioning devices are respectively located on the body positioning device. on both sides.

[0017] Specifically, the base of this assembly tool includes a rectangular base plate 4 and four legs 5 located at the four corners of the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com