Mounting structure of component in large-sized container

A technology for the installation of large-scale containers and components, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. Limits and other issues, to achieve the effect of easy non-destructive testing, greater freedom of work, and improved dimensional accuracy of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

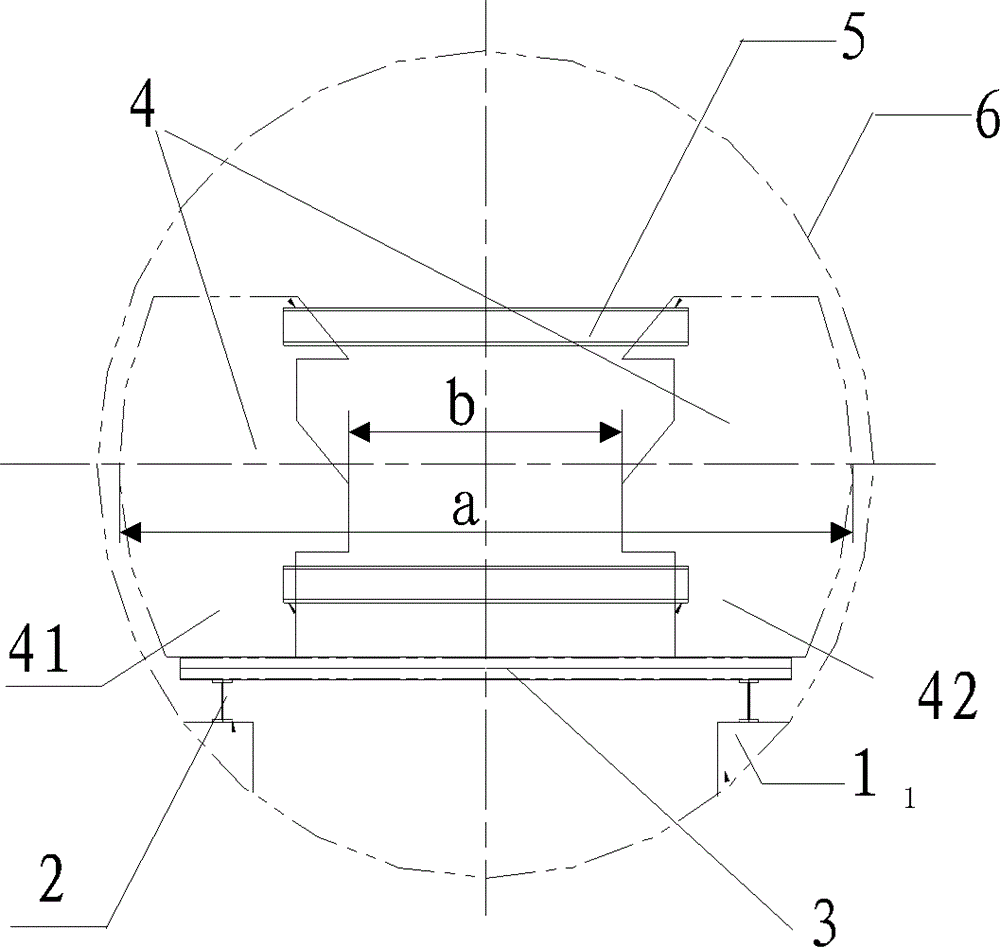

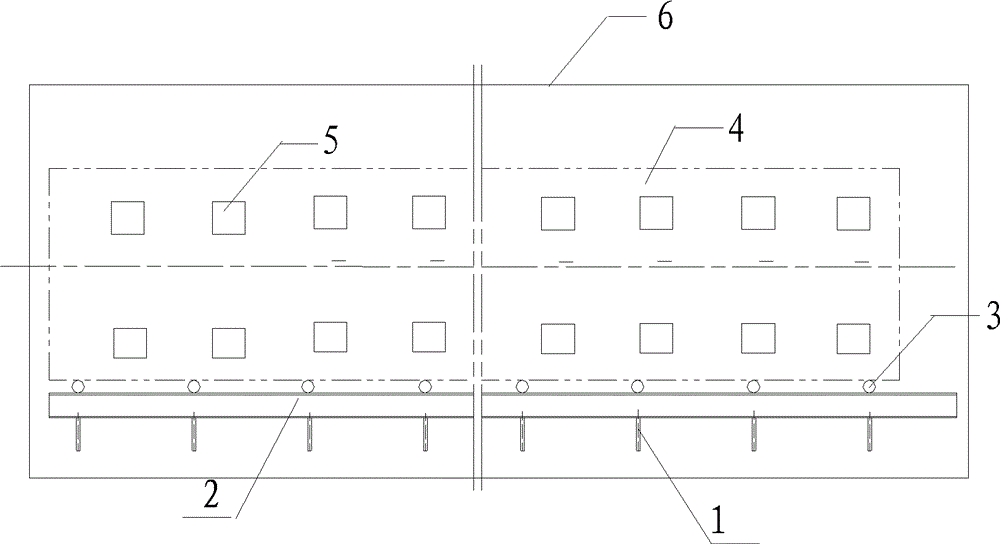

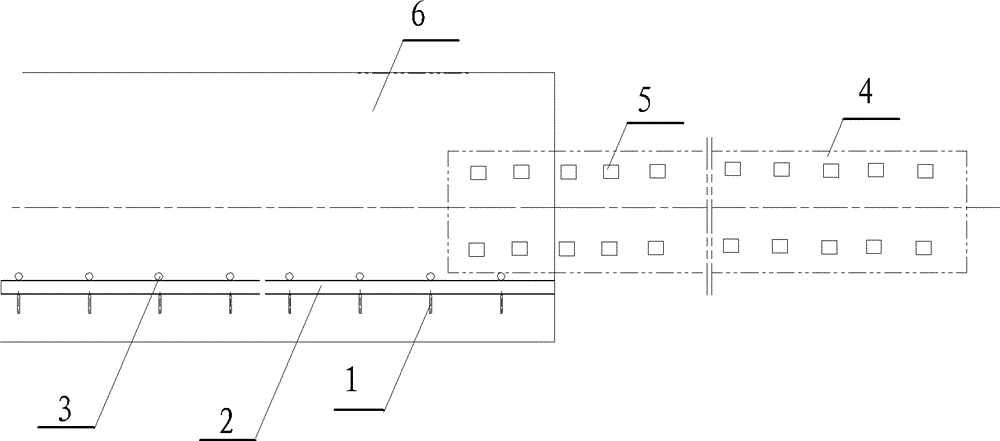

[0018] see Figure 1 to Figure 4 , in order to better understand the technical solution of the present invention, the following will be described in detail through specific embodiments and in conjunction with the accompanying drawings:

[0019] see figure 1 , a large container internal components installation structure of the present invention, including support plate 1, I-beam 2, process steel pipe 3, internal integral components 4 and process channel steel 5. Wherein the support plate 1 and the I-beam 2 constitute a mounting bracket, and the axial direction of the mounting bracket is parallel to the axial direction of the large container.

[0020] The support plates 1 are symmetrically arranged in two rows along the axial direction of the large container 6 on the bottom surface of the inner wall on both radial sides of the large container, and the I-beams 2 are erected symmetrically in two rows along the sides of the large container 6. On the top surfaces of the support pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com