Developer storing container and connecting member

A technology for connecting parts and developing agents, which is applied in the fields of instruments, electrography, optics, etc., and can solve problems such as toner ingress, fitting looseness, and insufficient transmission of driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

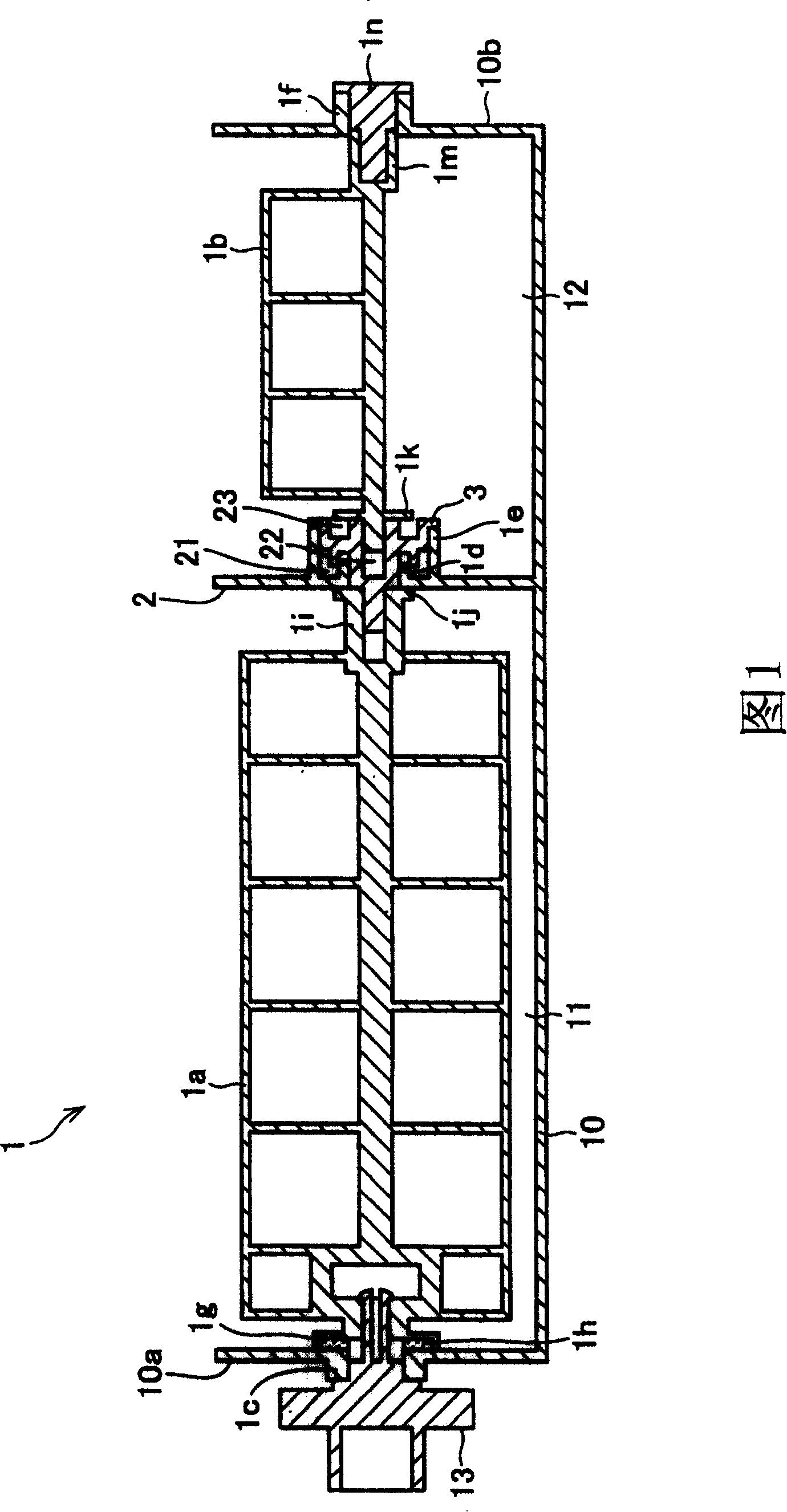

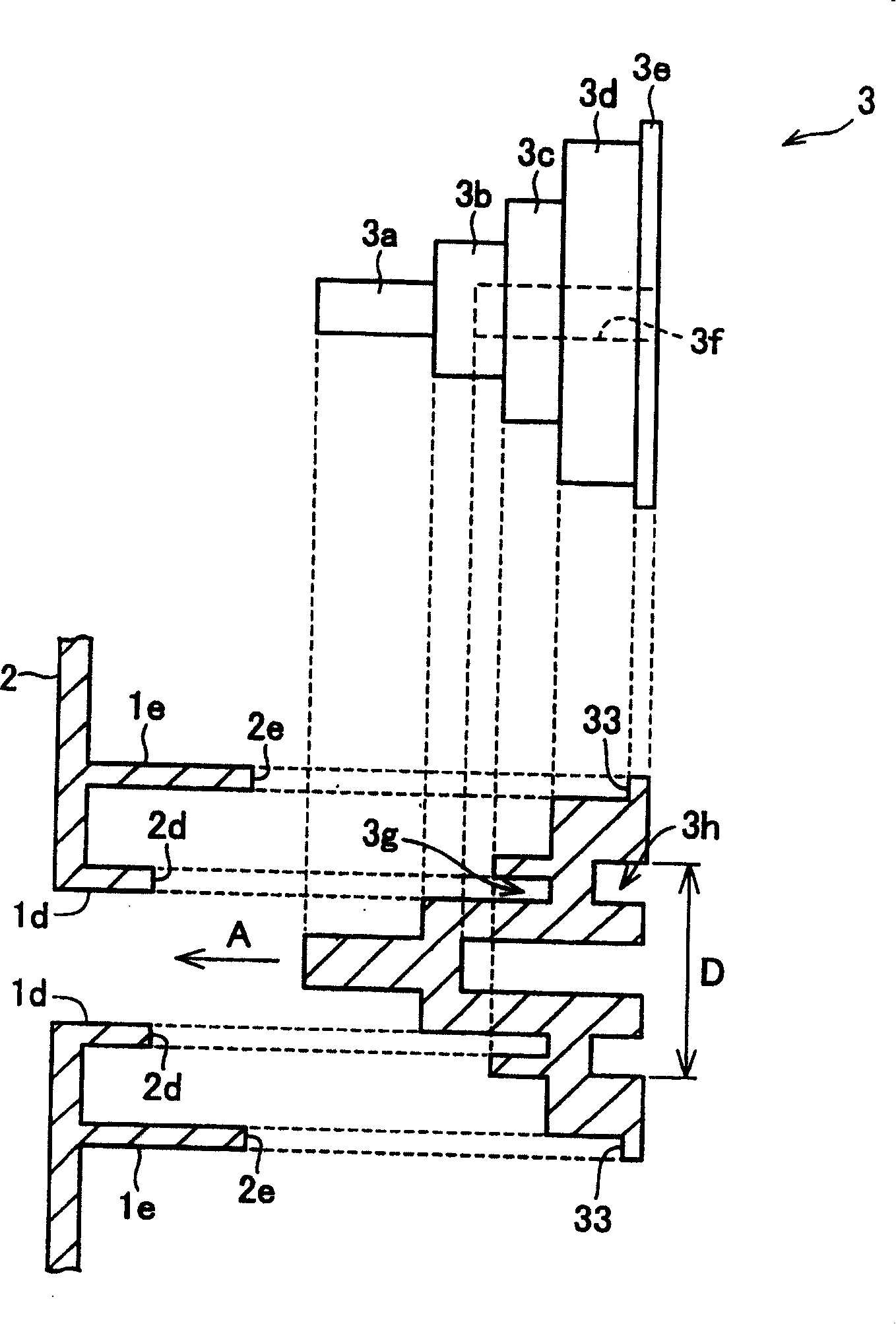

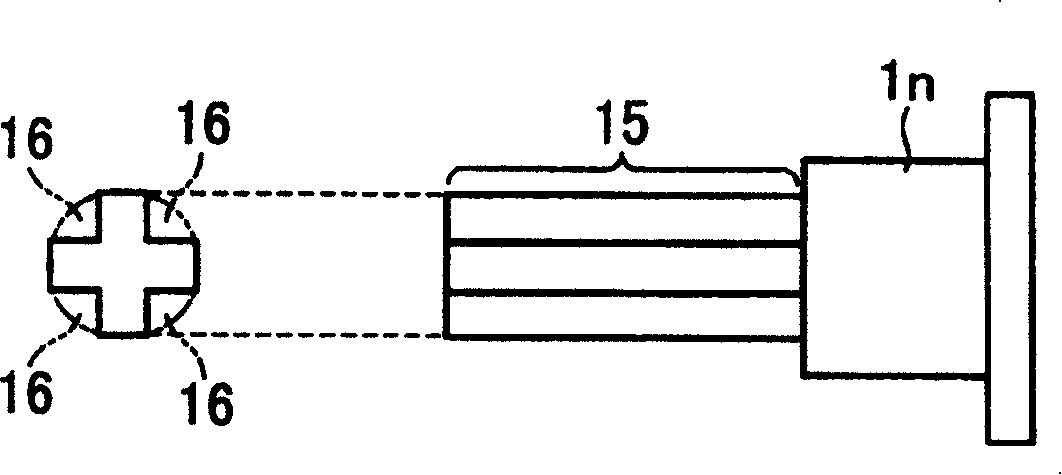

[0022] Below, refer to Figure 1- Figure 4 One embodiment of the present invention will be described.

[0023] FIG. 1 shows the structure of a toner cartridge (developer storage container) 1 according to this embodiment. This figure is a cross-sectional view along the rotation axis of the photoreceptor.

[0024] The toner cartridge 1 has a toner storage portion (developer storage portion) 11 and a waste toner storage portion (waste developer storage portion) 12 . The toner storage portion 11 and the waste toner storage portion 12 are formed by isolating the case 10 of the toner cartridge 1 with a partition wall (fixed wall) 2 and are adjacent to each other in the direction of the rotation axis described later. The partition wall 2 is integrally formed with the housing 10 of the toner cartridge 1 and fixed to the housing 10 . A stirring blade (developer stirring blade) 1 a is provided in the toner storage portion 11 . The stirring blade 1 a is constituted by a planar grid-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com