In-place finishing device and method for air bag polishing head

An airbag polishing and dressing device technology, applied in the field of polishing, can solve the problems of unsatisfactory effect, cumbersome preparation work, low polishing accuracy, etc., and achieve the effects of avoiding the influence of position installation errors, simple trimming preparation work, and high polishing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

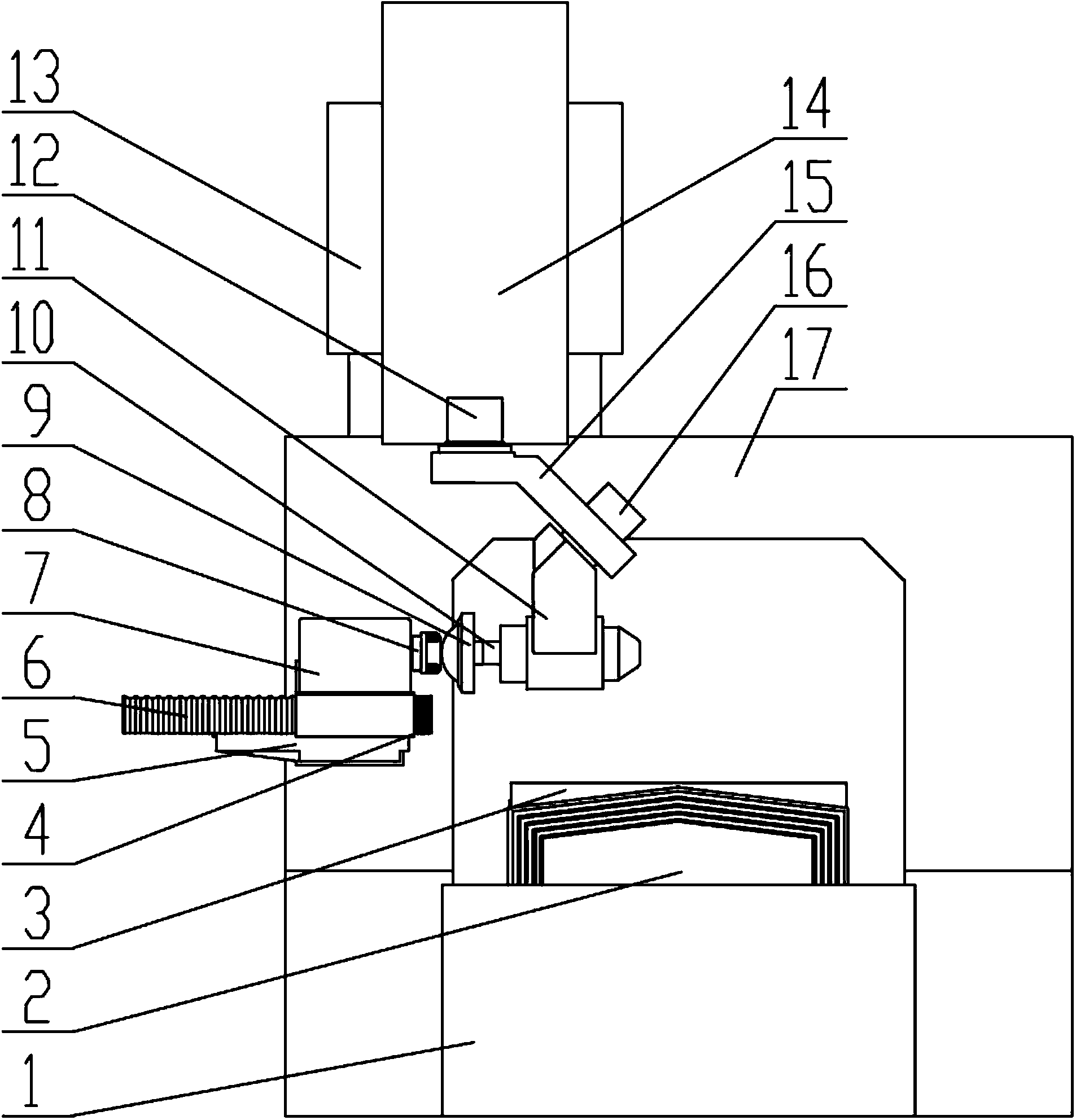

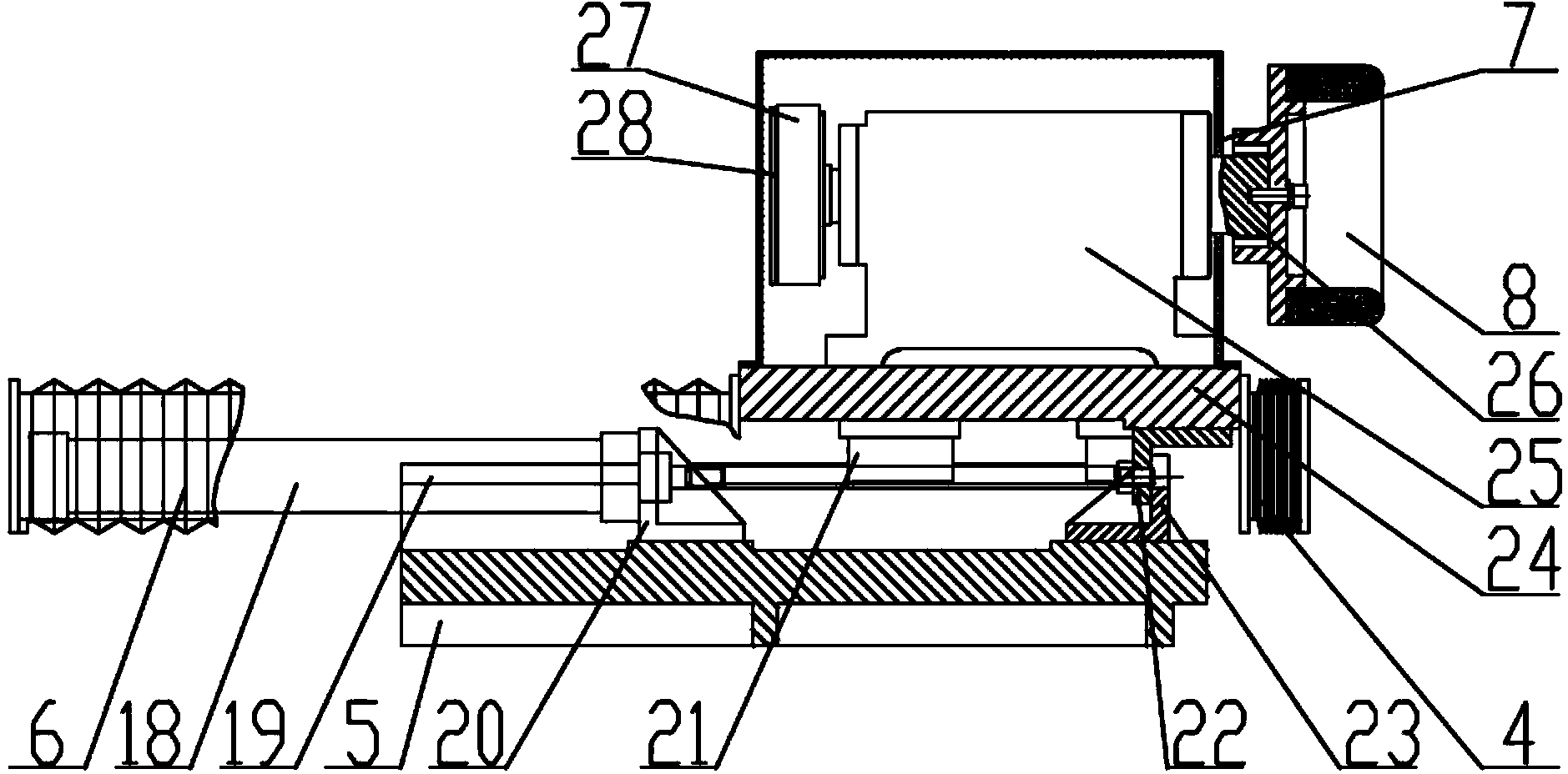

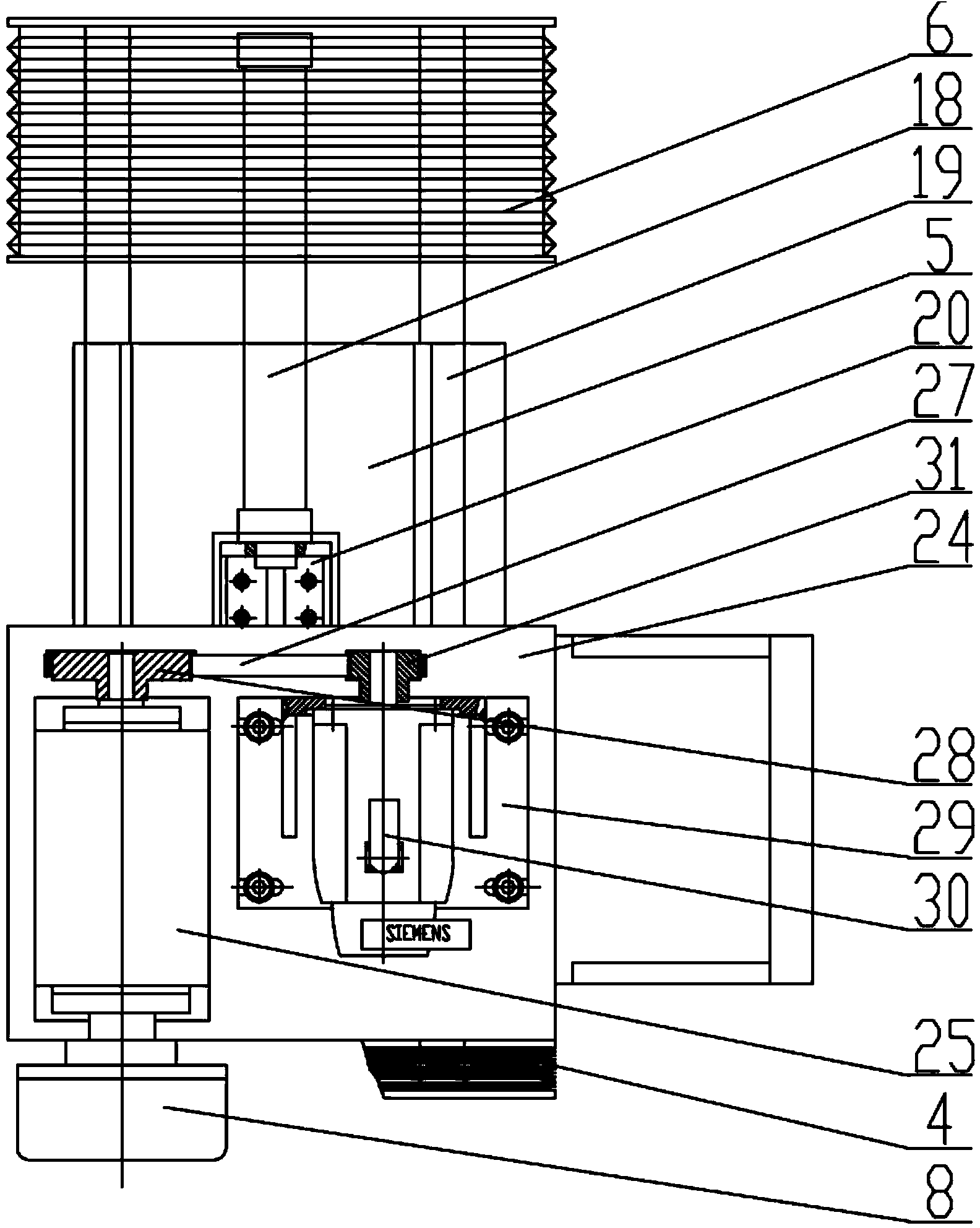

[0037] Embodiments of the present invention, such as figure 1 , figure 2 , image 3 , Figure 4 shown;

[0038]A trimming device for an in-position airbag polishing head. The trimming device includes a trimming device installed on a polishing machine tool and a moving part of the machine tool body. The machine tool body is provided with a base 1, and the base 1 is provided with a workbench 3 and a column 17. , the workbench 3 is provided with a telescopic protective cover 2, and the workbench 3 and the base 1 can move back and forth along the Y direction of the machine tool; the carriage 13 and the column 17 can move left and right along the X direction of the machine tool; The carriage 13 is connected with the carriage 13 to move up and down along the Z direction of the machine tool; the movement, swing and rotation of each part are connected through the signal control of the numerical control system; the A-axis motor 12 arranged at the lower end of the square box 14 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com