Device and method for detecting intensity of welding joint of electric resistance welding

A welding joint and strength detection technology, which is applied in the direction of resistance welding equipment, welding power supply, welding power supply, etc., can solve the problems of large fluctuations in the accuracy of measurement results, and a large amount of manpower and material resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

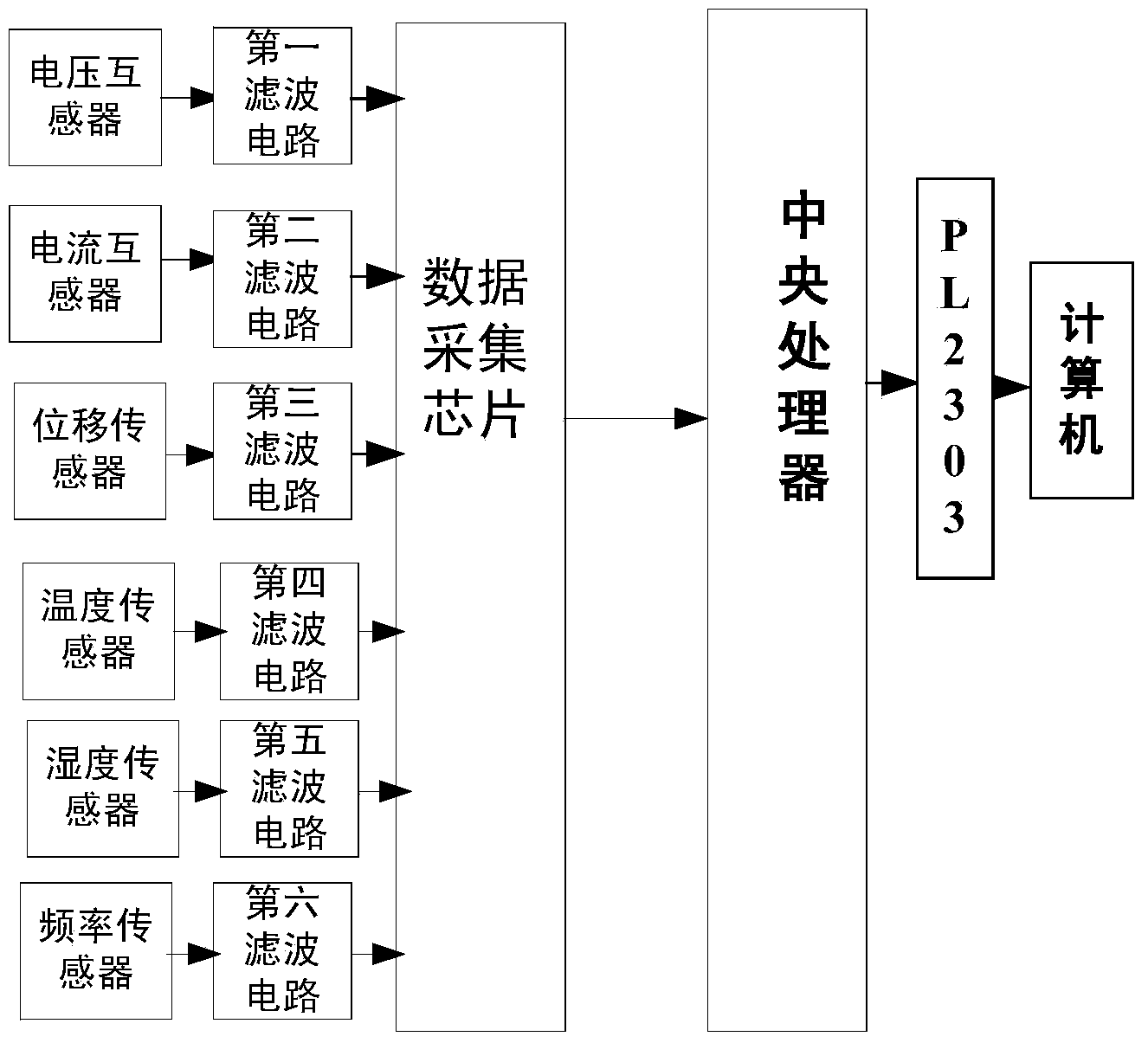

[0053] Such as figure 1 As shown, a resistance welding joint strength detection device includes a voltage transformer for detecting the working voltage of the welding machine, a current transformer for detecting the working current of the welding machine, a displacement sensor for detecting the moving speed of the welding machine, and A temperature sensor for detecting the temperature of the welding rod, a humidity sensor for detecting the ambient humidity, a frequency sensor for detecting the working frequency of the welding machine, a filter circuit, a data acquisition chip, a central processing unit and a computer;

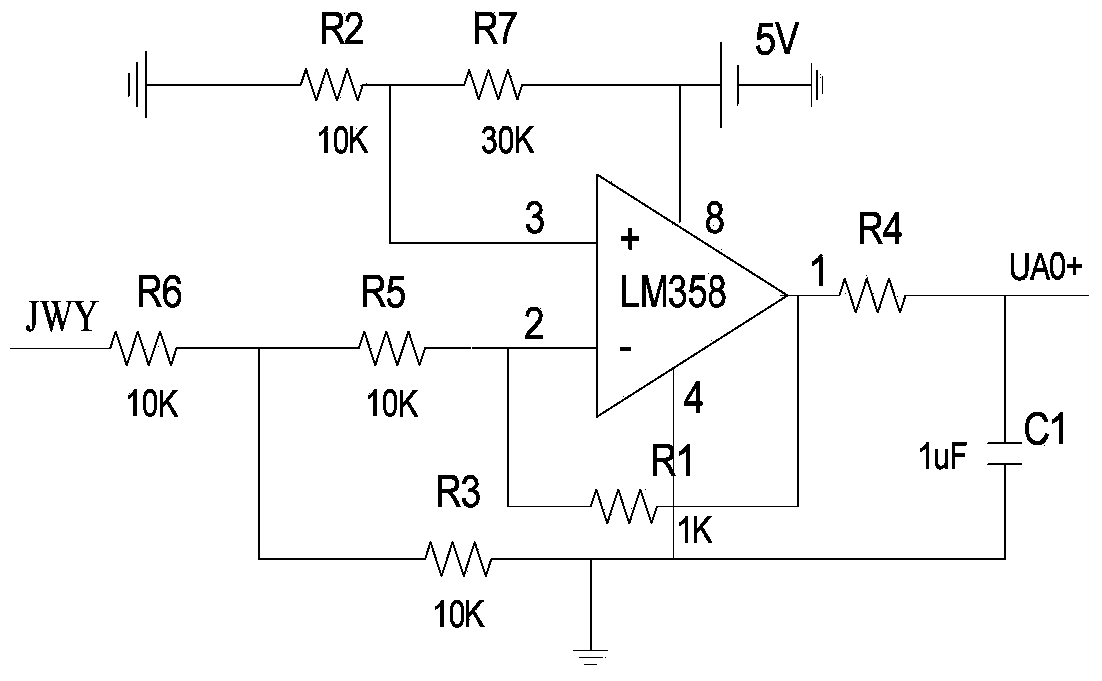

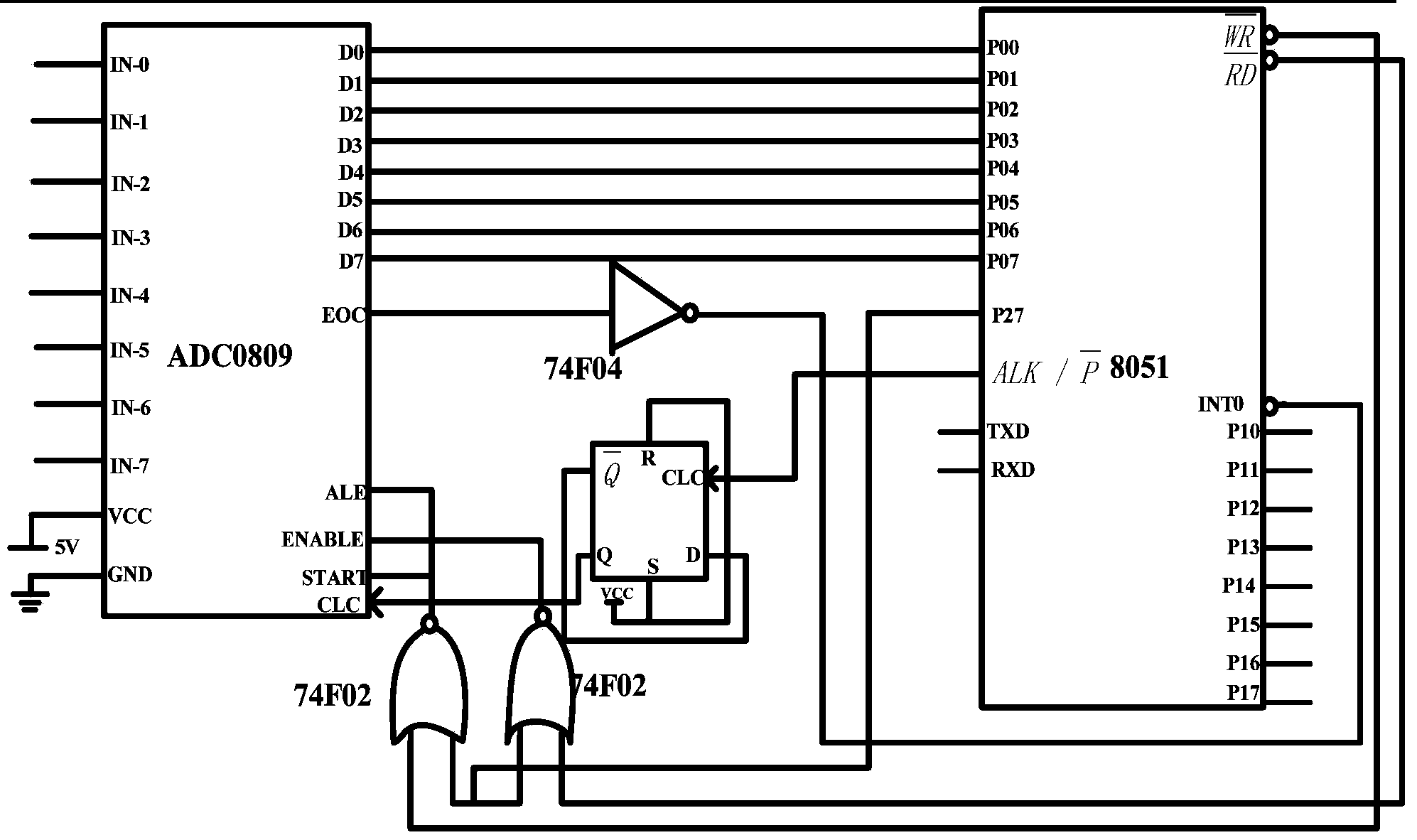

[0054] In the embodiment of the present invention, the JDG4-0.51000 / 100 model and the LZJC-10Q1000 / 5 model are selected for the voltage transformer and the current transformer respectively, and the working voltage and working current of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com