A low-entropy safe high-speed milling cutter design method and high-speed milling cutter

A design method and high-speed milling technology, applied in the direction of milling cutters, milling machine equipment, calculations, etc., can solve the problems of lack of effective communication and connection of high-speed milling cutter macro-mesoscopic motion, and the inability to quantitatively describe the motion state of milling cutter particle swarms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0076] The specific steps of a design method of a low-entropy safe high-speed milling cutter of the present embodiment are as follows:

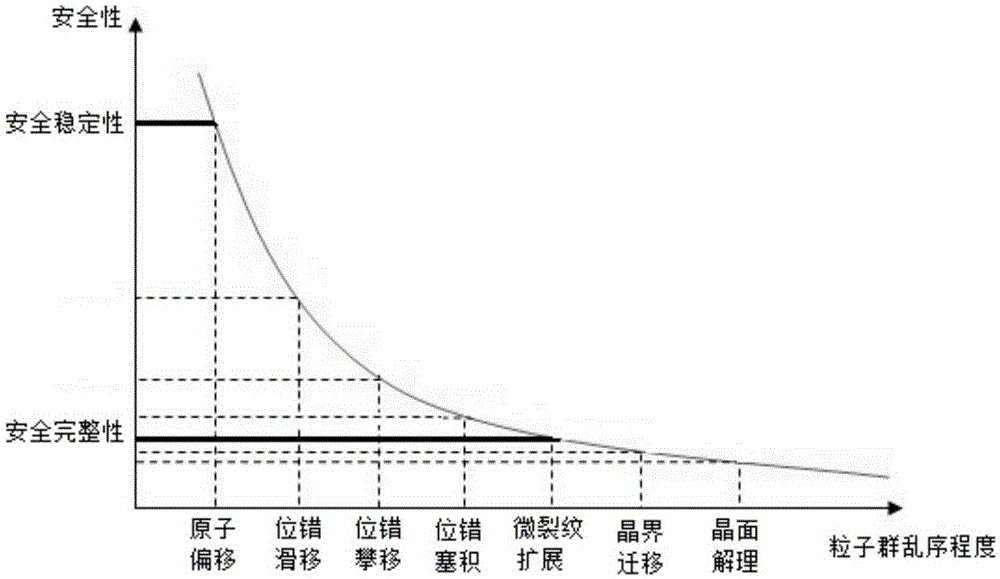

[0077] Step 1. Entropy model of safety decline of high-speed milling cutter

[0078] During the service of high-speed milling cutters, the particle swarm of the milling cutter assembly is in a gapless vibration state. Under the impact load of intermittent cutting, the particles deviate from the original stable position and move irregularly, resulting in the occurrence of disordered movement of the particle swarm; The higher the degree of group disorder, the more fragile the bonding force between the particle groups of the milling cutter component, and the more prone to dislocation slip, dislocation climb, dislocation accumulation, grain boundary migration, microcrack propagation, crystal plane cleavage, etc. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com