Numerical control milling and boring machine

A machine tool, milling and boring technology, applied in the field of processing machine tools, can solve the problems of increasing production costs, wasting resources, and not being able to use both milling and boring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

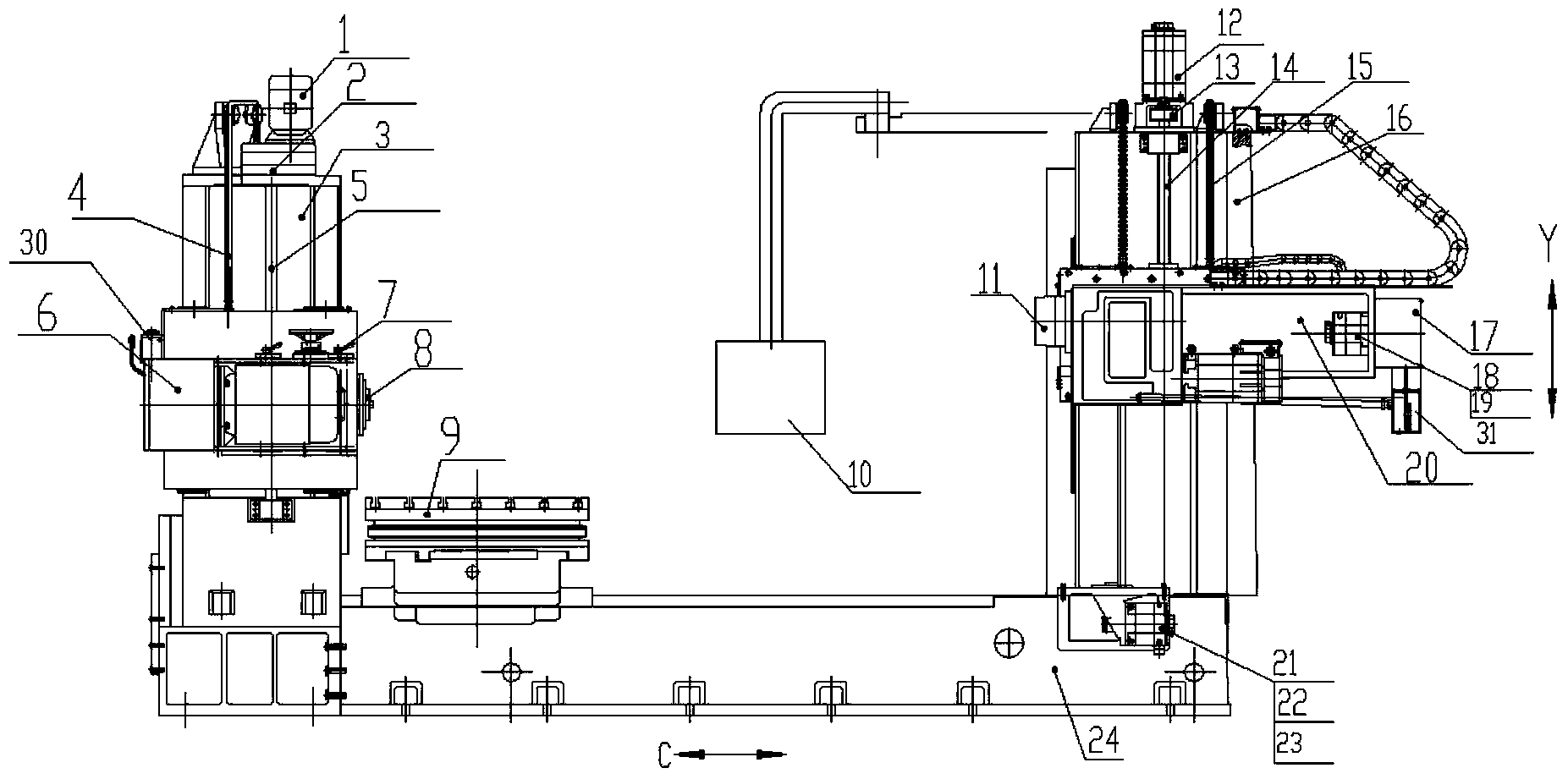

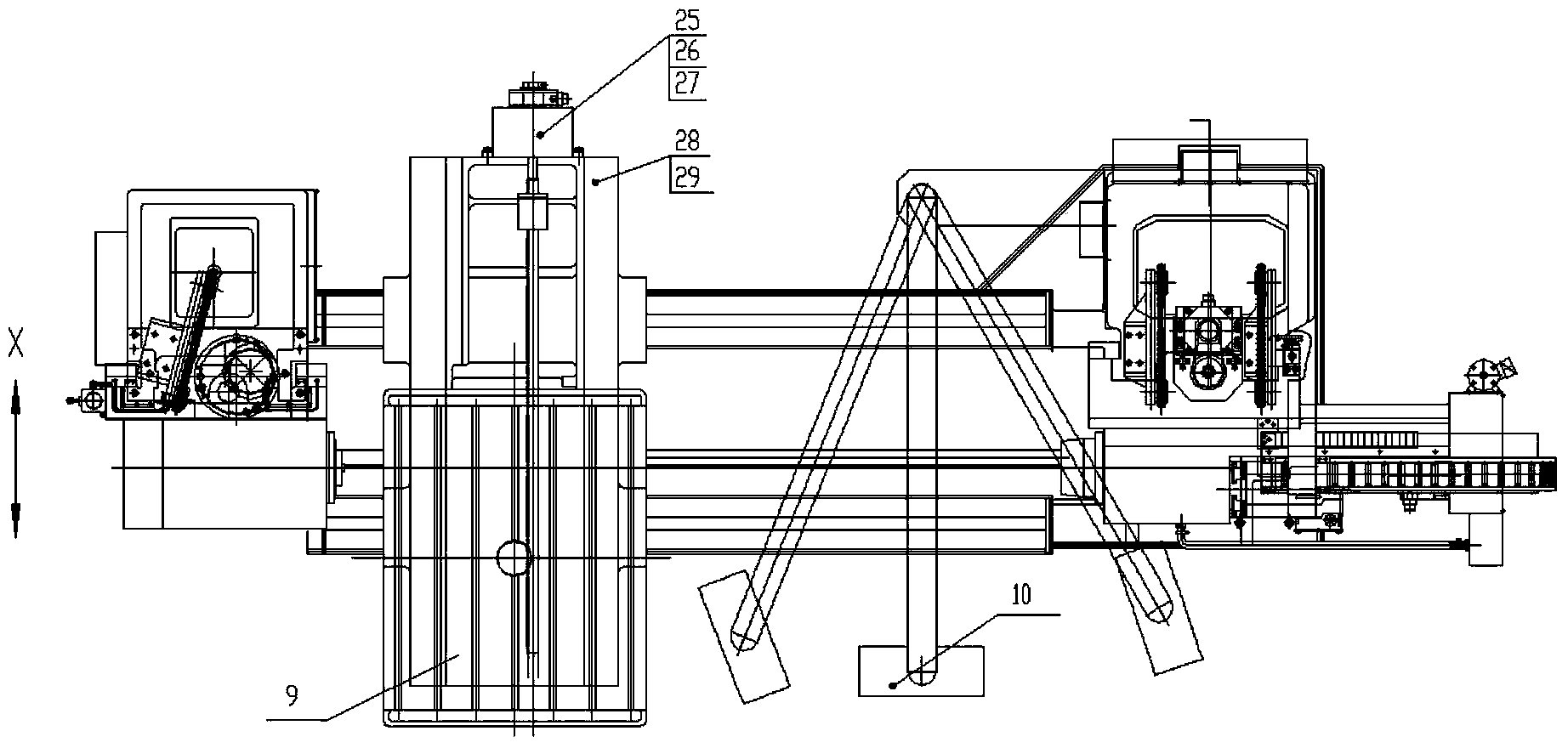

[0012] Such as figure 1 and figure 2 As shown, a kind of numerical control milling and boring machine tool comprises auxiliary column 3, workbench 9, numerical control operation panel 10, column 16, bed 24 and sliding seat 28; Both ends; the workbench 9 is on the slide 28; the slide 28 is on the bed 24, and the slide 28 is also equipped with a servo motor IV 25, a timing belt IV 26, a screw rod Ⅳ27 and protective device 29; the auxiliary column 3 is provided with a motor 1, a reduction box 2, a T-shaped lead screw 7 and a spindle box I6; the column 16 is provided with a servo motor I12, a synchronous belt I13, and a rolling screw Fu I14, balancing device II15, servo motor II17, synchronous belt II18, rolling scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com