A buoyancy element, riser assembly including a buoyancy element and a method of supporting a riser

A technology of buoyancy components and tube components, which is applied in the direction of drill pipes, casings, buoys, etc., and can solve problems such as moving troubles and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

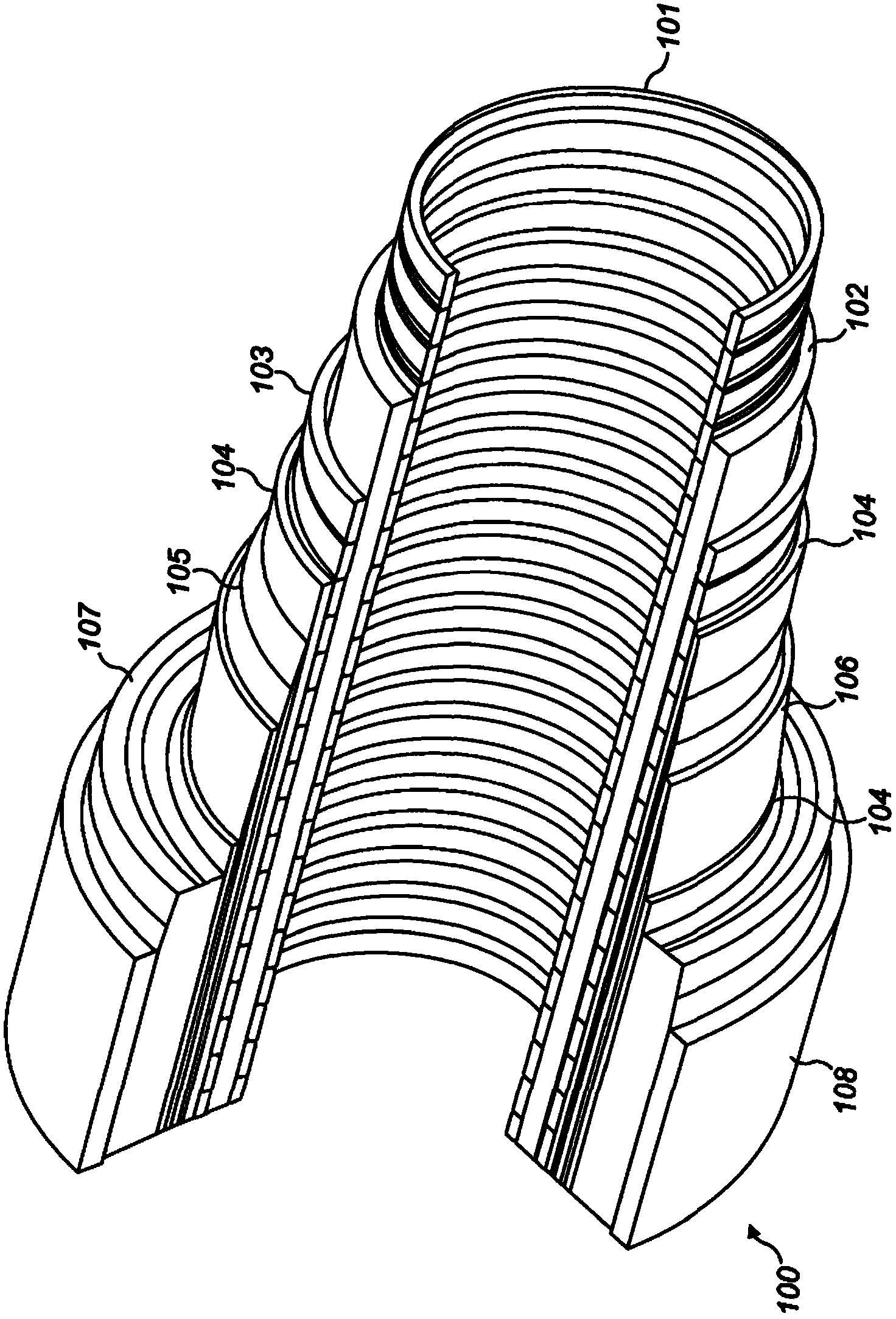

[0033] In this specification, flexible pipes will be introduced. It is to be understood that a flexible pipe is an assembly of a portion of a pipe body and one or more end fittings in each end fitting in which a respective end of the pipe body terminates. figure 2 Illustrated is the manner in which the tubular body 100 is formed from a combination of layered materials forming a pressure-bearing conduit according to one embodiment of the invention. although figure 2 A number of specific layers are shown in , it being understood that the invention is broadly applicable to coaxial tubular body structures comprising two or more layers fabricated from a wide variety of possible materials. Note also that layer thicknesses are shown for illustration purposes only.

[0034] Such as figure 2 As shown, the tubular body includes an optional innermost carcass layer 101 . The carcass provides an interlocking structure that can act as an innermost layer, fully or partially preventing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com