Modularized thyristor valve block for solid combination switch device

A technology of thyristor valve and compound switch, which is applied to electronic switches, electro-solid devices, electrical components, etc., can solve the problems of a large number of high-frequency energy-transmitting devices, difficult installation of plug-in terminals, and a large amount of processing and installation. Small, consistent, and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

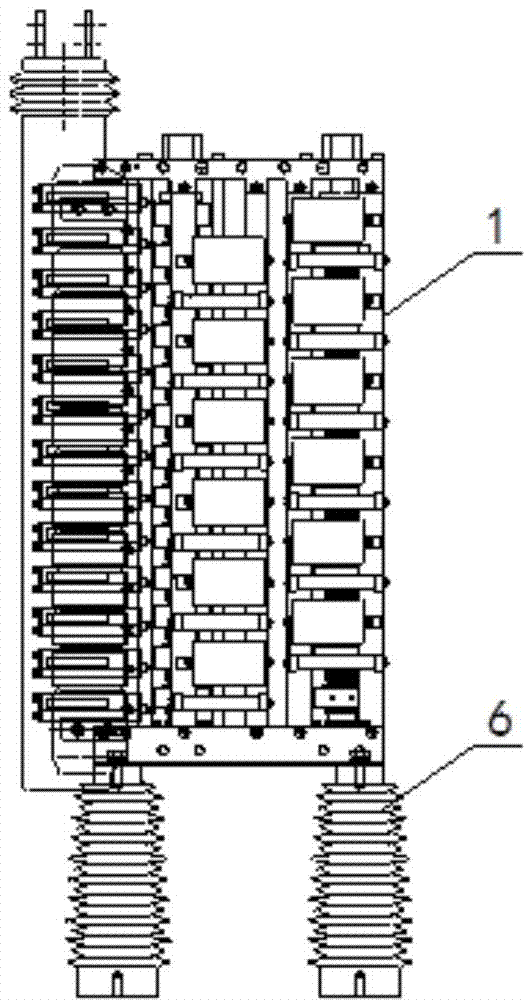

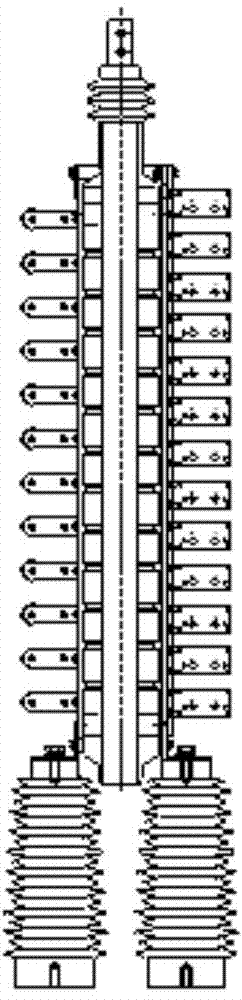

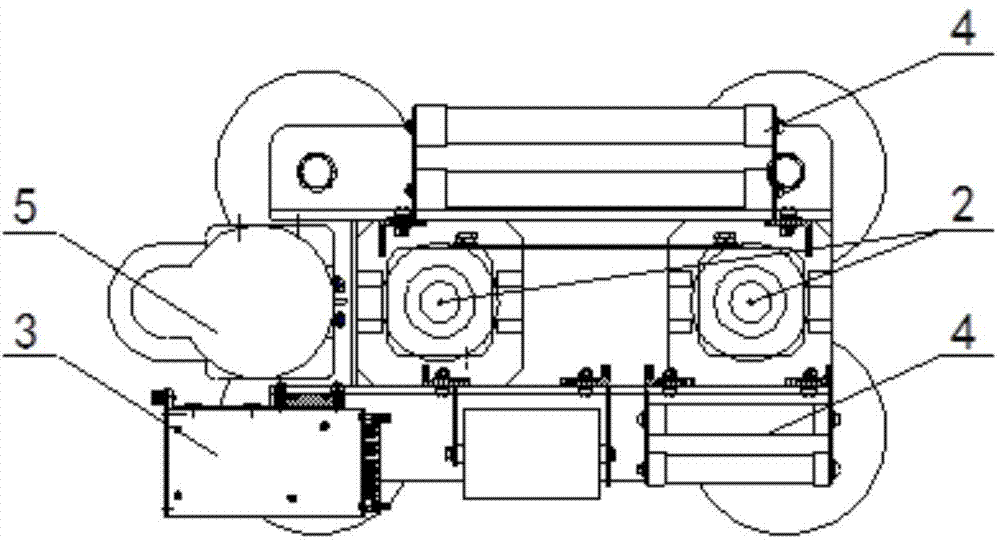

[0039] This embodiment takes the modular thyristor valve group for solid-state composite switchgear as an example, such as Figure 1 to Figure 8 As shown, the modular thyristor valve group for solid-state composite switchgear provided by the embodiment of the present invention includes: modular thyristor valve group 1, thyristor valve string assembly 2, TCU board assembly 3, RC and voltage equalizing assembly 4, high frequency Energy sending component 5, epoxy cast insulator 6, thyristor 7, radiator 8, disc spring mechanism 9, upper flange 10, lower flange 11, epoxy pull belt 12, TCU board card 13, TCU board shielding box 14, Fixed plate 15, connecting terminal 16, voltage equalizing resistor 17, absorbing capacitor 18, supporting fixed plate 19, high frequency energy transmission CT20, fixing piece 21, primary side coil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com