Low-voltage efficient motor high heat conduction and insulation structure and manufacturing method thereof

A technology of insulating structure and manufacturing method, which is applied in the shape/style/structure of winding insulation, manufacturing of motor generators, chemical instruments and methods, etc., can solve the problem that the insulating structure cannot achieve high-efficiency motors, the thermal conductivity of insulating adhesives is low, and it is difficult to Realize problems such as improving motor efficiency, and achieve the effect of overcoming poor thermal conductivity, decreasing average temperature rise, and decreasing calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

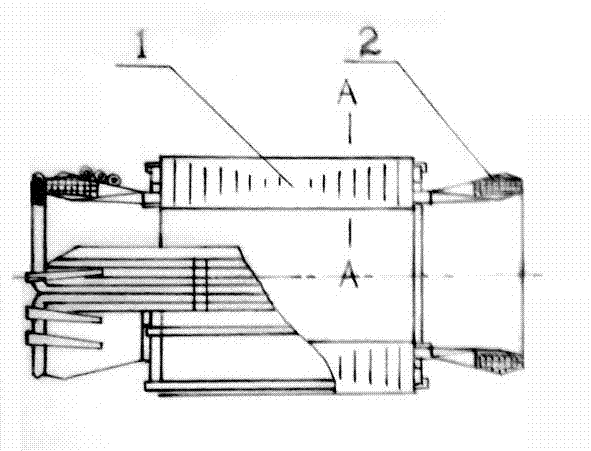

Image

Examples

Embodiment 1

[0039] The high thermal conductivity and insulation composite adhesive described in the present invention, the weight ratio of each component raw material can be: 60 parts of insulating adhesive, 5 parts of aluminum nitride, 5 parts of aluminum oxide, 2 parts of diamond, 2 parts of anti-precipitation agent 1 part, 2 parts of organic soil, its preparation method can be carried out according to the preparation steps of the high thermal conductivity composite insulating glue described in the above-mentioned specific embodiment.

Embodiment 2

[0041] The high thermal conductivity and insulation composite adhesive described in the present invention, the weight ratio of each component raw material can also be: 65 parts of insulating adhesive, 17 parts of aluminum nitride, 17 parts of aluminum oxide, 6 parts of diamond, anti-precipitation agent 3 parts, 3 parts of organic soil, its production method can be carried out according to the production steps of the high thermal conductivity composite insulating glue described in the above-mentioned specific embodiment.

Embodiment 3

[0043] The high thermal conductivity and insulation composite adhesive described in the present invention can also have the weight ratio of each component raw material: 70 parts of insulating adhesive, 30 parts of aluminum nitride, 30 parts of aluminum oxide, 10 parts of diamond, anti-sedimentation agent 4 parts, 4 parts of organic soil, its production method can be carried out according to the production steps of the high thermal conductivity composite insulating glue described in the above-mentioned specific embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com